Automatic capsule filling filler

Model: NJP-3800C

Production capacity: 228000 grains/hour

Machine weight: 2200kg

Machine size: 1395*1180*2260mm

Optional: Powder feeder

Power supply: 220/380V, 50hz, 10.5kw

Number of holes: 27 holes

Certificate: CE, ISO9001, GMP, FAT

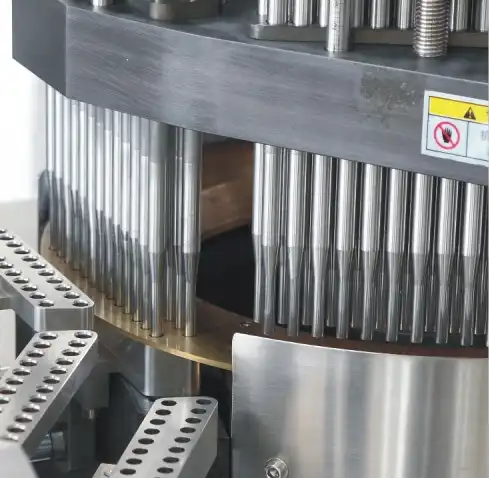

Automatic Capsule Filling Filler: High-Performance Solution for Your Production Needs

Are you looking for a reliable Automatic capsule filling filler to boost your pharmaceutical production? With the ability to hold 228,000 pills per hour, our NJP-3800C type works very well. This high-tech machine blends precise engineering with easy operation. Every time, you get the same results. This equipment is great for any high-demand setting, like a pharmaceutical plant, a health product center, or a hospital preparation room.

Main Parameter

| Feature | Description |

|---|---|

| Model | NJP-3800C Best Automatic Capsule Filling Machine |

| Output Capacity | 228000 capsules/hour |

| Filling Precision | ±1% |

| Applicable Capsule Sizes | #00, 0, 1, 2, 3, 4, 5 |

| Machine Dimensions | 1395*1180*2260mm |

| Power Supply | 220/380V/50Hz |

| Air Consumption | 0.4m³/min |

| Automation Level | Siemens touch screen |

| Filling material | Powder, granules, particles |

Why Choose Us?

Superior Production Capacity

Up to 228,000 pills can be processed by the NJP-3800C every hour. With this fast performance, your production lines will keep running smoothly. You save a lot of time and money on work. All capsule sizes can be filled accurately thanks to the 27-hole design.

Compact Yet Powerful Design

Even though it produces a lot, this machine takes up very little space. With dimensions of 1395 x 1180 x 2260 mm and a weight of 2200 kg, it fits easily into most industrial settings. You make the most of the floor room you have while still being very productive.

Versatile Power Options

Our machine accommodates different power requirements with 220V/380V options at 50Hz. The 10.5kW power consumption delivers excellent energy efficiency. You reduce operational costs while maintaining peak performance throughout extended production runs.

Advanced Features That Set Us Apart

Precision Engineering

Before being put together, each part goes through a series of strict quality checks. The machine consistently makes capsules with little waste. You get accuracy at the medicinal level with every run. Our tech team has made sure that every part is reliable and accurate.

Optional Powder Feeder System

Enhance your production capabilities with our optional powder feeder attachment. This upgrade streamlines your filling process for powder-based formulations. You gain additional flexibility for diverse product lines without purchasing separate equipment.

User-Friendly Operation

The intuitive control panel makes operation straightforward for your team. Training time is minimal, and maintenance procedures are clearly documented. You reduce downtime and keep production schedules on track consistently.

Quality Certifications You Can Trust

Our Automatic capsule filling filler meets international quality standards including CE, ISO9001, and GMP certifications. These credentials demonstrate our commitment to excellence and regulatory compliance. Your facility maintains the highest standards required for pharmaceutical manufacturing.

The FAT (Factory Acceptance Testing) certification ensures every machine performs to specifications before shipping. You receive equipment that's ready for immediate production use.

Quality Control

Comprehensive Support Services

Installation and Commissioning

Our technical team provides on-site installation and commissioning support. We ensure your new equipment integrates smoothly with existing production lines. You minimize startup delays and achieve optimal performance from day one.

Warranty Protection

Every purchase includes free spare parts coverage for one full year. This comprehensive warranty protects your investment and reduces maintenance costs. Our proven technical team stands behind every machine we manufacture.

Expert Technical Support

Our multilingual support team understands international pharmaceutical requirements. We provide guidance throughout the equipment lifecycle. You get answers quickly when questions arise during operation or maintenance.

Our Wearhouse

Ideal Applications

This versatile equipment serves multiple industries effectively:

- Pharmaceutical manufacturing facilities

- Health product and supplement companies

- Hospital preparation departments

- Food processing operations

- Chemical manufacturing plants

The product adapts to various capsule types and formulations. You gain flexibility to expand product offerings as market demands change.

Professional Export Packaging

We protect your investment with GMP-compliant wooden box packaging. This robust protection ensures safe delivery regardless of shipping distance. Your equipment arrives in perfect condition and ready for installation.

Cooperation Cases of Best Automatic Capsule Filling Machine

Contact Us

Ready to Transform Your Production?

Transform your capsule production with our advanced Automatic capsule filling filler. Contact our team at michelle@factopintl.com to discuss your specific requirements. We'll help you select the perfect configuration for maximum productivity and return on investment.

YOU MAY LIKE