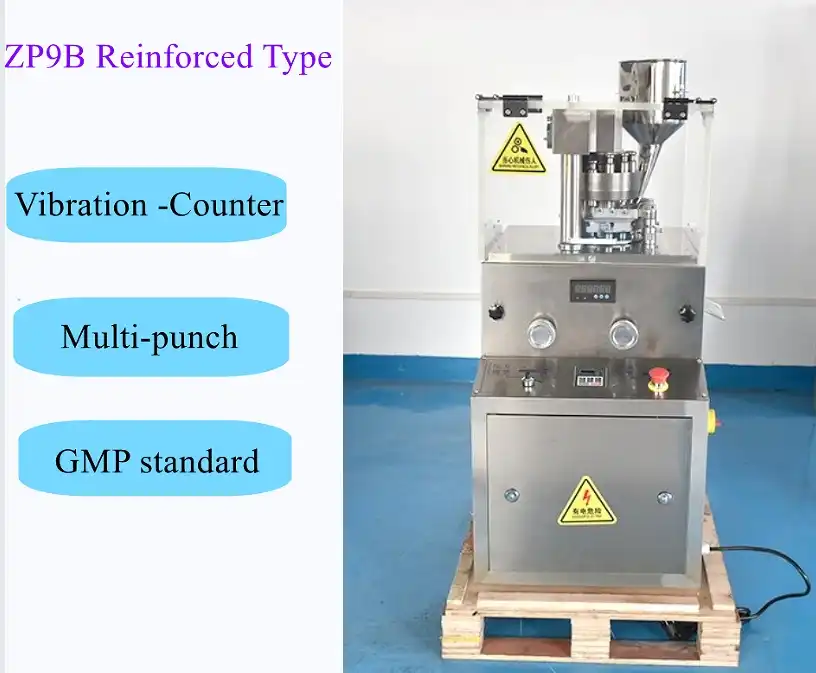

Laboratory tablet press machine

Punch die: 9 sets

Voltage: 110/220/380V, 2.2kw

Function: Enhanced

Stock: In stock

Certificate: CE, ISO9001, GMP standard

Laboratory Tablet Press Machine ZP9B - Professional Pharmaceutical Equipment

Are you looking for a reliable Laboratory tablet press machine to enhance your pharmaceutical production? Pharmaceutical factories, health product factories, and study labs can all get great results from the ZP9B model. This high-tech machine is great for small-scale production and quality testing because it blends precise engineering with easy operation. With 9 punch dies and different voltage settings, you can always get the same tablet shape.

Product Main Parameter

| Feature | Specification |

|---|---|

| Model | ZP9B laboratory tablet press |

| Pressure Control | Precise, adjustable pressure |

| Output Capacity | 16200 tablets per hour |

| Tablet Diameter | 3 mm to 20 mm |

| Motor Power | 2.2 kW |

| Speed | Adjustable, up to 60 RPM |

| Weight | 220 kg |

| Dimensions | 620*450*1020 mm |

| Certification | ISO 9001, CE |

| Warranty | 12 months |

Key Features of Our Laboratory Tablet Press Equipment

Advanced Engineering Design

The structure of the ZP9B type is strong and meets GMP standards. You'll like how the carefully designed parts keep the tablet's weight and hardness constant. The machine works easily and doesn't shake much, which keeps your valuable recipes safe.

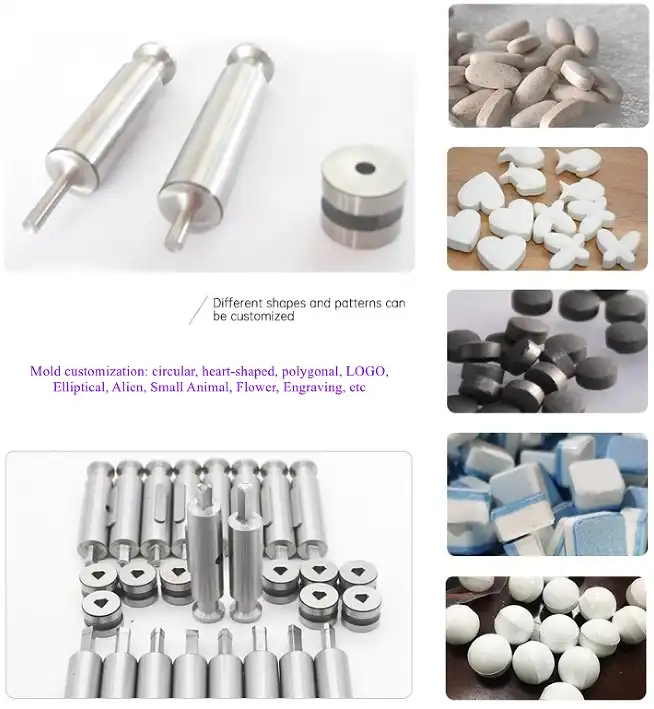

Versatile Operation Capabilities

This equipment easily works with tablets of different sizes and types. You are able to change the squeezing force to suit your needs. The 9-punch die design makes small-batch production quick and easy while keeping quality high.

User-Friendly Interface

It's easy to use the machine, even for beginners. You save time with clear settings and simple upkeep steps. Because it's small, it works perfectly in labs without sacrificing utility.

Tablet machine real detail photos

Technical Specifications

- Model: ZP9B

- Punch Dies: 9 sets

- Power: 2.2kw

- Voltage Options: 110V/220V/380V

- Certification: CE, ISO9001, GMP compliant

- Availability: In stock for immediate delivery

Why Choose Factop's Tablet Pressing Solutions?

Proven Manufacturing Excellence

Factop has years of experience making machines for making medicines. Our technology team knows the specific problems you have to deal with when making tablets. Our name is based on providing reliable tools that goes above and beyond what the business requires.

Global Quality Standards

Every Laboratory tablet press machine undergoes rigorous testing before shipment. FAT testing and certification support ensure you receive equipment that performs flawlessly from day one. Our GMP-certified factory guarantees consistent quality across all products.

Quality Control

Comprehensive Support Services

You receive more than just equipment when you choose Factop. On-site installation and commissioning support help you get started quickly. Our multilingual technical team provides ongoing assistance whenever you need it.

Reliable After-Sales Service

We're confident in our goods, so we offer a full guarantee. When you get free parts for the first year, you don't have to worry. Fast shipping means that if new parts are needed, there will be little downtime.

Applications Across Industries

Pharmaceutical Manufacturing

Research laboratories rely on our equipment for formulation development. Quality control departments use our machines for batch testing and validation. The consistent results help streamline your approval processes.

Health Product Production

Nutraceutical companies appreciate the versatility of our tablet press systems. You can process various supplement formulations with confidence. The equipment handles different powder characteristics effectively.

Food Industry Applications

Food manufacturers use our product for specialty products. The food-grade construction ensures safe processing of edible formulations. Easy cleaning procedures maintain hygiene standards.

Application Areas

Quality Assurance and Compliance

Our manufacturing facility maintains strict quality control protocols. Every component undergoes thorough inspection before assembly. The final testing phase ensures optimal performance under various operating conditions.

Wooden box export packaging protects your investment during shipping. We follow international packaging standards to prevent damage during transit. Detailed installation manuals accompany every shipment.

Packaging and Transportation

Getting Started with Your Equipment

Installation support makes setup straightforward and efficient. Our technicians guide you through the commissioning process step by step. Training ensures your operators understand all safety procedures and operational requirements.

Regular maintenance schedules keep your equipment running smoothly. We provide detailed maintenance guides and ongoing technical support. Replacement parts are readily available through our global distribution network.

Our company and customer

Contact Us

Ready to enhance your tablet production capabilities? Contact our experienced team at michelle@factopintl.com to discuss your specific requirements. We'll help you select the perfect Laboratory tablet press machine configuration for your applications and provide comprehensive support throughout your journey.