Tablet Pill Press

No. of station: 25 punches

Function: Double-color tablets produce

Delivery time: 20 days

Max pressure: 120KN

Weight: 2100kg

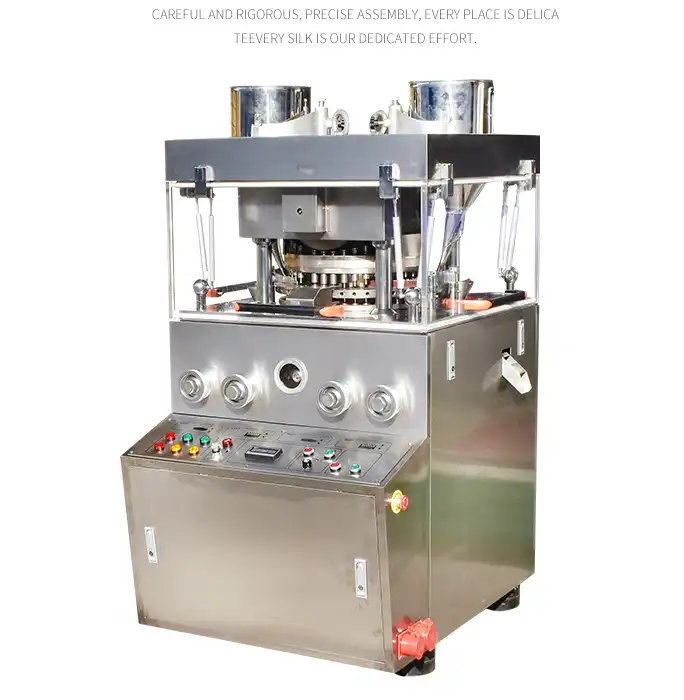

High-Performance Tablet Pill Press - ZP420-25D Double-Color Technology

Looking for a reliable Tablet Pill Press that delivers consistent, high-quality results? You've found the perfect solution. Our ZP420-25D model is perfect for pharmaceutical manufacturers, health product firms, and research centers throughout the world since it combines cutting-edge engineering with easy-to-use operation. With its remarkable accuracy and efficiency, this double-color tablet production equipment guarantees that your tablet manufacturing satisfies the highest industry requirements. This device manages rigorous production schedules while consistently producing tablets of exceptional quality because to its sturdy design and 25 punches.

Product Main Parameter

| Feature | Details |

|---|---|

| Model | ZP420-25D tablet pill maker |

| Output Capacity | 120000 pcs/hour |

| Tablet Weight Range | 0.1g - 100g |

| Die Set Options | 25 punches |

| Maximum Pressure | 100 kN |

| Tablet press diameter | 25mm |

| Dimensions (LxWxH) | 1230*950*1670mm |

| Weight | 1700kg |

ZP-35D make testing before shipping

Advanced Features That Set Our Press Apart

Dual-Color Tablet Production

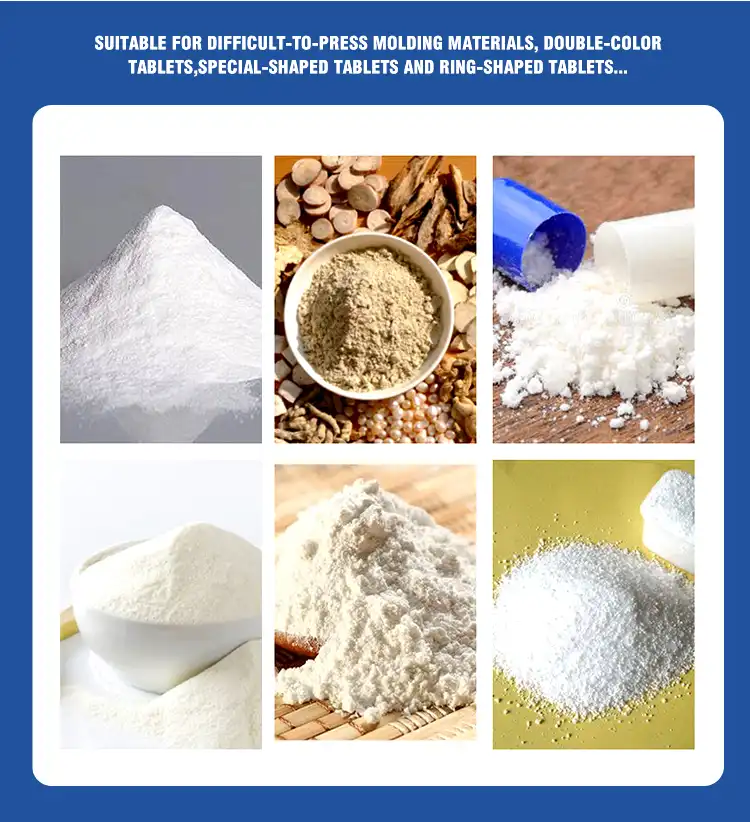

A speciality of the ZP420-25D is producing beautiful double-color tablets. Producing aesthetically pleasing items that stand out in the market is made possible by this feature. Whether you're producing pharmaceutical tablets, vitamins, or supplements, the dual-color capabilities gives your goods a polished appearance.

Powerful Performance Specifications

This machine is capable of handling even the most difficult tablet formulas, with a maximum pressure of 120KN. The 25-punch setup maintains uniform tablet weight and hardness while guaranteeing effective production speeds. The sturdy design, weighing 2100 kg, ensures stability while in use, minimizing vibration and guaranteeing accurate tablet creation.

GMP-Certified Quality Standards

Strict GMP certification standards are met by our production facilities. This indicates that each machine is put through a rigorous quality test before to being sent. You may be confident in your production procedures since the equipment you get conforms with worldwide pharmaceutical manufacturing standards.

Quality Control

Why Choose Factop's Tablet Manufacturing Solutions?

Proven Expertise and Experience

Factop brings years of specialized experience in pharmaceutical machinery manufacturing. Our technical team understands the unique challenges you face in tablet production. We've helped companies across America, Europe, South Africa, Korea, Philippines, and Indonesia achieve their manufacturing goals.

Comprehensive Support Package

When you invest in our Tablet Pill Press, you receive much more than just equipment. Our package includes:

- Fast 20-day delivery timeline

- Complete wooden box export packaging

- FAT testing and certification documentation

- Free spare parts for one full year

- On-site installation and commissioning support

Global Service Network

Our multilingual professional team understands international trade procedures. We handle export documentation, shipping logistics, and customs requirements. This expertise ensures smooth delivery to your facility, regardless of location.

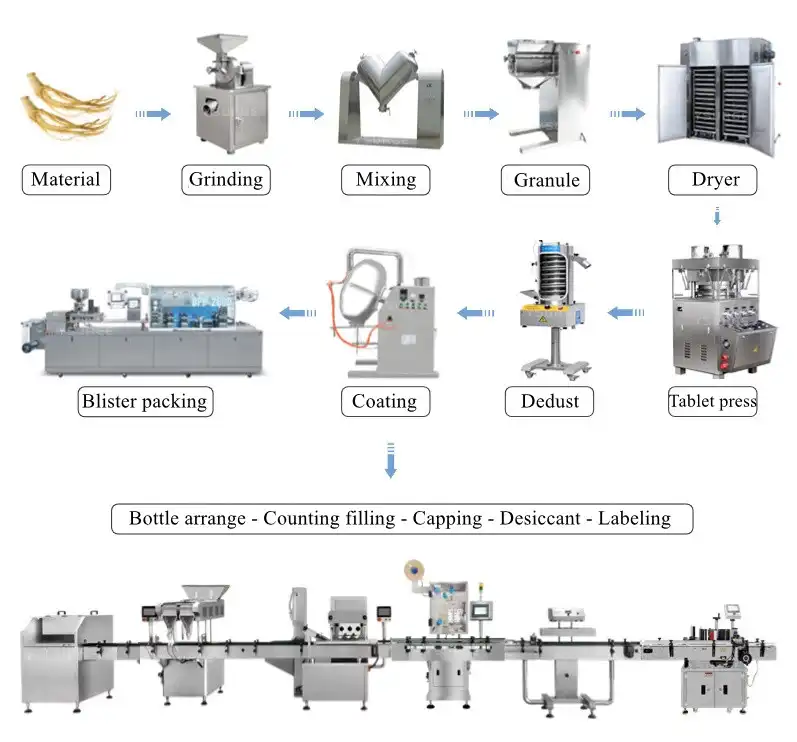

Production Process

Perfect Applications for Your Industry

Pharmaceutical Manufacturing

Pharmaceutical companies rely on our equipment for producing prescription medications, over-the-counter drugs, and specialty formulations. The precise pressure control and consistent tablet formation meet strict regulatory requirements.

Health Product Production

Supplement manufacturers appreciate the dual-color capability for creating attractive vitamin tablets, mineral supplements, and herbal products. The visual appeal helps products stand out on retail shelves.

Hospital Preparation Rooms

Hospital pharmacies use our compact yet powerful systems for preparing custom tablet formulations. The reliable operation ensures consistent medication dosing for patient safety.

Food and Chemical Industries

Food supplement producers and chemical companies benefit from the versatile tablet formation capabilities. The robust construction handles various powder formulations and binding agents.

Application Areas

Technical Excellence You Can Trust

Quality Assurance Process

Every product undergoes comprehensive testing before shipment. Our FAT (Factory Acceptance Testing) protocol verifies all mechanical functions, pressure settings, and safety systems. You receive detailed certification documentation for your quality records.

Installation and Training Support

Our technical specialists provide on-site installation and commissioning services. This hands-on support ensures optimal machine setup and operator training. Your team learns proper operation procedures, maintenance schedules, and troubleshooting techniques.

Long-Term Partnership Approach

Factop believes in building lasting relationships with customers. Our "integrity, innovation, cooperation, and win-win" philosophy guides every interaction. We're committed to your long-term success, not just initial equipment sales.

Our Customer Feedback

Our Company Workshop

Contact Us

Ready to enhance your Tablet Pill Press production capabilities? Contact our expert team at michelle@factopintl.com for detailed specifications, pricing information, and custom configuration options that perfectly match your manufacturing requirements.

YOU MAY LIKE