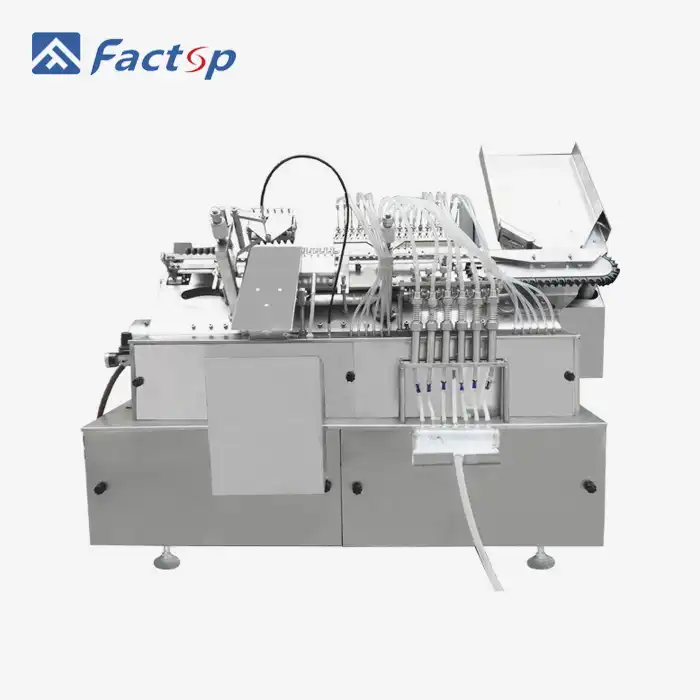

Ampoule Filling System

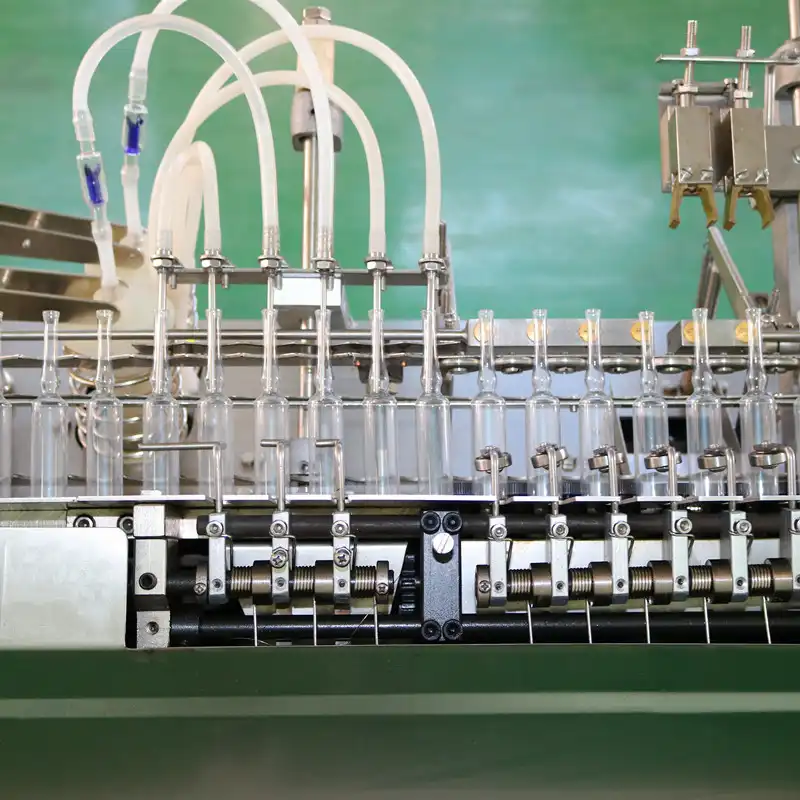

Filling head: 6

Suit bottle: 60-70mm

Suitable: Filling packing

Stock: In stock

Ampoule Filling System: Professional Pharmaceutical Packaging Solution

Looking for a reliable Ampoule Filling System to enhance your pharmaceutical production? For today's pharmaceutical companies, our ALG-6 model offers precise filling technology. Filling your ampoule manufacturing demands has never been easier than with this state-of-the-art machine. Our filling equipment is up to the high standards your business requires, having performed admirably in a wide range of sectors.

Specifications

| Feature | Specification |

|---|---|

| Model | ALG-6 Ampoule filling machine manufacturer |

| Ampoule type | 1-2ml, 5-10ml, 20ml |

| Production capacity | 150-160 bottle/min |

| Power Supply | 380V, 50Hz |

| Power | 0.84kw |

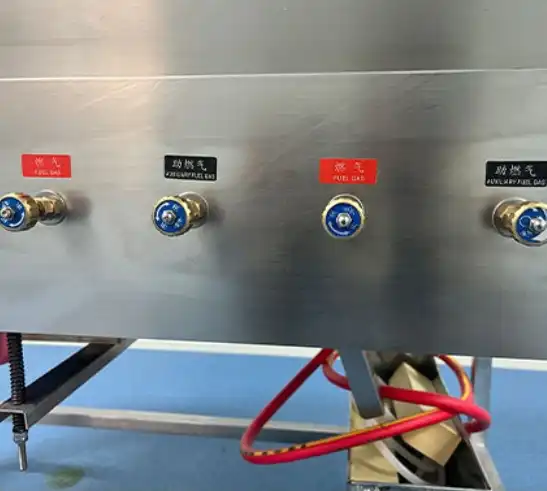

| Sealing gas | Gas/liquefied gas+oxygen |

| Gas volume | LPG/Pied Gas 2-2.5m3/h |

| Machine weight | 300kg |

| Dimensions | 1700*900*1350 mm |

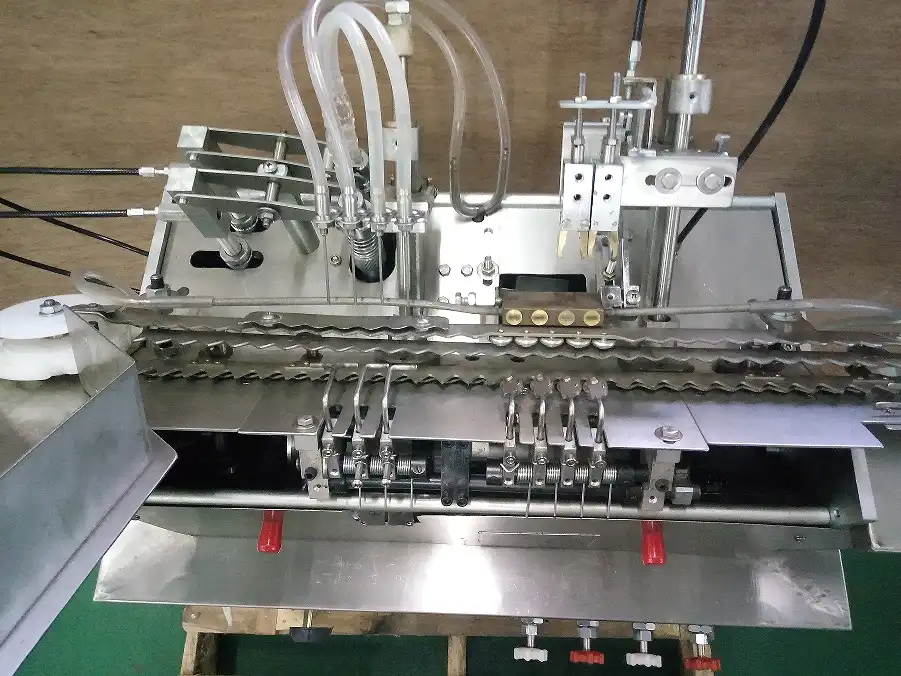

Advanced Technology for Precise Filling Operations

The ALG-6 model features six precision filling heads that deliver exceptional accuracy. Each head operates independently to maintain consistent fill volumes across your production run. Your bottles measuring 60-70mm fit perfectly within this system's specifications.

This equipment handles various liquid formulations with ease. Whether you're processing vaccines, injectable medications, or sterile solutions, the system maintains product integrity throughout the filling process. Temperature-sensitive products remain stable during operation.

The controls on this machine were made by our technical team with the user in mind. Operators don't need a lot of training to swiftly change the filling parameters. Quicker setup and less production delays are the results of the user-friendly interface.

GMP-Certified Manufacturing Excellence

Quality assurance drives every aspect of our manufacturing process. Our GMP-certified facility ensures each machine meets international pharmaceutical standards. Rigorous testing protocols verify performance before shipment.

When shipped internationally, your investment will be protected by the wooden box export packing. All units are certified after passing FAT testing and receiving the appropriate paperwork. This all-encompassing method ensures that your equipment is delivered in an installation-ready state.

Your production facility benefits from our proven technical expertise. Our experienced team understands pharmaceutical manufacturing requirements across different markets. We've successfully delivered solutions to facilities in America, Europe, South Africa, Korea, Philippines, and Indonesia.

Quality Control

Comprehensive Support Services

Installation and commissioning support comes standard with your purchase. Our technicians travel to your facility to ensure proper setup and optimal performance. This hands-on approach minimizes downtime and accelerates production startup.

Free spare parts accompany your investment for the first year. This coverage protects your operation from unexpected maintenance costs. Our fast delivery system ensures replacement components reach you promptly when needed.

Technical support for the Ampoule Filling System extends beyond installation. Our multilingual team provides ongoing assistance throughout your equipment's lifecycle. We understand international trade procedures and can navigate complex logistics requirements efficiently.

Production Process

Versatile Applications Across Industries

Pharmaceutical factories rely on our filling systems for critical medication production. The sterile design prevents contamination while maintaining high throughput rates. Regulatory compliance becomes straightforward with our documented quality processes.

Health product makers value the system's flexibility. Different formulations work well together without having to go through long switching processes. Your production plan works well for all of your products.

Hospital preparation rooms benefit from the compact design and reliable operation. Limited space requirements make installation feasible in existing facilities. Clean-in-place capabilities support stringent hygiene protocols.

For specific liquid goods, food and chemical plants use this technology. The strong construction can handle different chemical makeup and viscosities. Consistently accurate filling cuts down on waste and raises profits.

Application Area

Expert Partnership for Long-Term Success

Our trade logic centers on judgment, advancement, participation, and shared victory. These values direct each client interaction and drive nonstop enhancement in our arrangements. Your victory straightforwardly contributes to our notoriety in the worldwide commercial center.

The skilled foreign trade team at Factop knows how hard it is to do business in your market. We work together with partners to find chances and get past problems. We know the market very well, which helps you stay competitive in fields that change quickly.

Long-term associations characterize our approach to client connections. Or maybe than straightforward hardware deals, we construct collaborative collusions that back your development targets. This item speaks to the starting of our beneficial organization.

Packaging and Transportation

Ready to Transform Your Production

Contact our team today to discuss your specific Ampoule Filling System requirements. We'll provide detailed specifications and customization options for your application. Email michelle@factopintl.com to start your journey toward enhanced pharmaceutical manufacturing capabilities.

YOU MAY LIKE