wet mixing granulator

Suitable: Powder, solid

Applicable: Chemical, pharmaceutical, food

Stock: In stock

Brand: Factop

High-Speed Wet Mixing Granulator Machine - Professional Pharmaceutical Equipment

Looking for reliable granulation equipment for your pharmaceutical production? Our high-speed wet mixing granulator delivers exceptional performance for powder and solid materials. Mixing and granulating are both done efficiently by this high-tech machine. You'll get particles of the same size and better flow qualities for your goods. You can use this tools to make granules whether you are working with chemicals, food products, or pharmaceutical compounds.

The small form fits right into production lines that are already in place. Your workers will like how easy the settings are to use and how safe the machine is. The granulator machine makes sure that the mixture is mixed evenly and that the quality of the product is maintained throughout the process.

Specifications

| Feature | Specification |

|---|---|

| Model | GHL-50 |

| Volume | 50L |

| Working volume | 12-36L |

| Loading capacity | 6-18kg |

| Max inside diameter | 498mm |

| Rotational speed of stiring paddle | 50-500rpm |

| Stirring motor | 5.5kw |

| Rotational speed of cutter | 50-3000mm |

| Cutting motor | 1.5kw |

| Discharge in left | Length 2100mm, Width 780mm |

| Height of discharge cutter | 725mm |

| Machine height | 1500mm |

| Weight | 420kg |

Key Features and Benefits

Superior Mixing Performance

The high-speed impellers in our grinding tools make the best conditions for mixing. The bowl form was carefully chosen to make sure that all the material moves freely. You always get the same granules with the same amount of wetness spread out.

The variable speed control allows precise adjustment for different formulations. Your production team can easily optimize settings for various materials and batch sizes.

Robust Construction and Design

Built with pharmaceutical-grade stainless steel, this machine meets stringent industry standards. The smooth interior surfaces prevent product contamination and enable easy cleaning. All contact parts comply with GMP requirements for pharmaceutical manufacturing.

The sealed mixing chamber prevents dust emission during operation. Your facility maintains a clean working environment while protecting operator safety.

Versatile Application Range

This equipment handles diverse materials across multiple industries:

- Pharmaceutical: Tablet granulation, capsule fillings, and powder blends

- Food Industry: Seasoning mixes, instant products, and nutritional supplements

- Chemical Processing: Detergent powders, agricultural chemicals, and specialty compounds

The adjustable spray system accommodates different binder solutions and granulation liquids. You can process both water-based and solvent-based formulations effectively.

Application Areas

Technical Specifications and Performance

Capacity Options

Available in multiple bowl sizes to match your production requirements. Batch capacities range from laboratory scale to full production volumes. The wet mixing granulator processes materials efficiently regardless of batch size.

Control System

Advanced PLC control system provides precise parameter monitoring. Touch screen interface displays real-time processing data including:

-

Mixing speed and time

-

Spray rate control

-

Temperature monitoring

-

Safety status indicators

Safety Features

Multiple safety interlocks protect operators and equipment. Emergency stop functions halt operation immediately when needed. The enclosed design contains any potential splashing or spillage during processing.

Why Choose Factop International Trade Company?

Manufacturing Excellence

Factop specializes in pharmaceutical machinery with decades of industry experience. Our GMP-certified factory ensures every machine meets international quality standards. You receive equipment that performs reliably in demanding production environments.

Global Service Network

We serve customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our multilingual technical team understands international trade requirements and local regulations.

Comprehensive Support

Every purchase includes:

-

Factory Acceptance Testing (FAT) certification

-

Wooden box export packaging for safe shipping

-

Free spare parts for one year

-

On-site installation and commissioning support

-

Technical training for your operators

Quality Assurance

Our proven technical team ensures each product undergoes rigorous testing before shipment. We stand behind our equipment with comprehensive warranties and ongoing technical support.

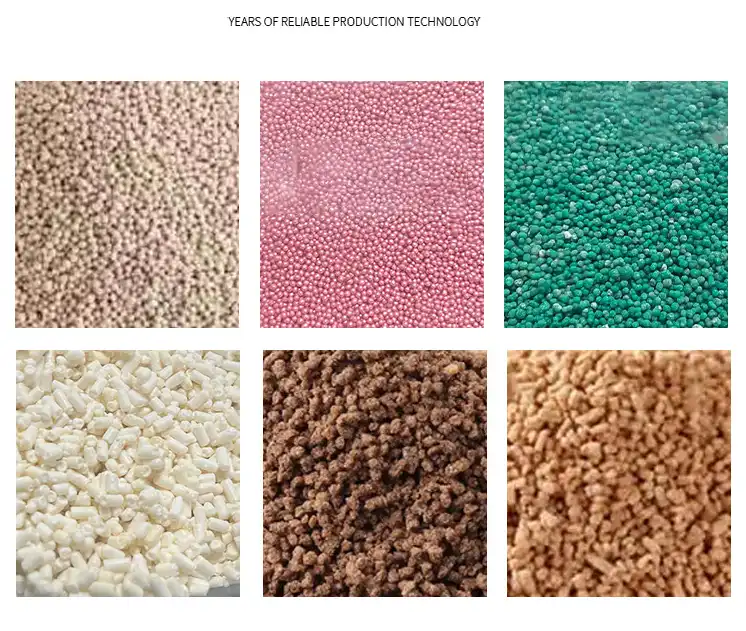

Production Process

Applications Across Industries

Pharmaceutical Manufacturing

Ideal for tablet production facilities, capsule manufacturing, and hospital preparation rooms. The equipment handles active pharmaceutical ingredients safely while maintaining product potency.

Food and Supplement Production

Perfect for health product factories and food processing facilities. Create uniform granules for instant drinks, seasoning blends, and nutritional supplements.

Chemical Processing

Suitable for specialty chemical production requiring precise mixing and granulation. Handle various chemical compounds with confidence in product consistency.

Contact Us

Ready to enhance your production capabilities? Our wet mixing granulator delivers the performance and reliability your operation demands. Contact our expert team at michelle@factopintl.com to discuss your specific requirements and receive a customized solution for your facility.

YOU MAY LIKE