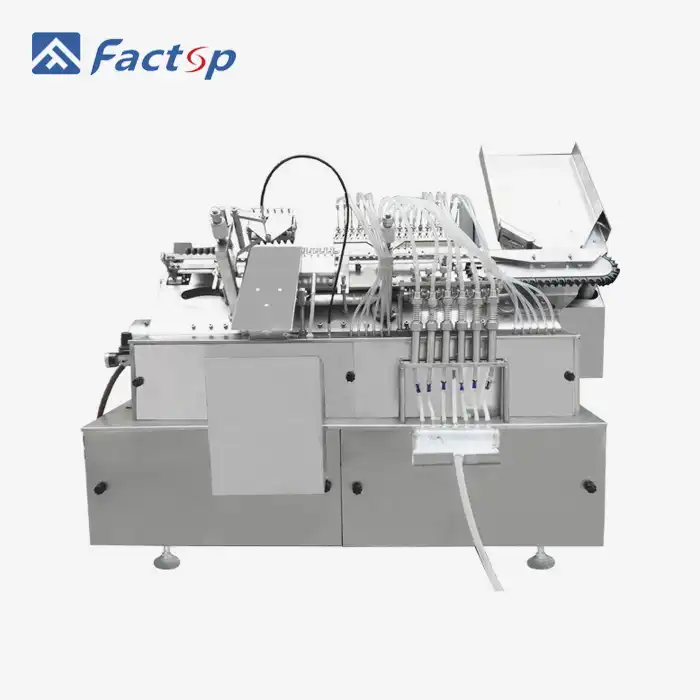

8 head ampoule filling machine

Filling head: 8

Suit bottle: 60-70mm

Suitable: Filling packing

Stock: In stock

8 Head Ampoule Filling Machine - High-Precision Pharmaceutical Solution

When you need reliable, precise filling equipment for your pharmaceutical manufacturing, our 8 head ampoule filling machine delivers exceptional performance. Modern engineering meets intuitive design in this state-of-the-art ALG-8 model. It's ideal for healthcare product manufacturing, pharmaceutical warehouses, and operating rooms in hospitals. The machine guarantees constant precision while upholding the utmost quality standards that your consumers anticipate. You may increase your production capacity by a large margin without sacrificing accuracy or quality control with eight filling heads operating in tandem.

Specifications

| Feature | Specification |

|---|---|

| Filling Heads | 8 Head Ampoule Filling Machine |

| Ampoule type | 1-2ml, 5-10ml, 20ml |

| Capacity | 200-250 ampoule/min |

| Power Supply | 380V / 50Hz |

| Control System | PLC-based with touch screen interface |

| Motor power | 840W |

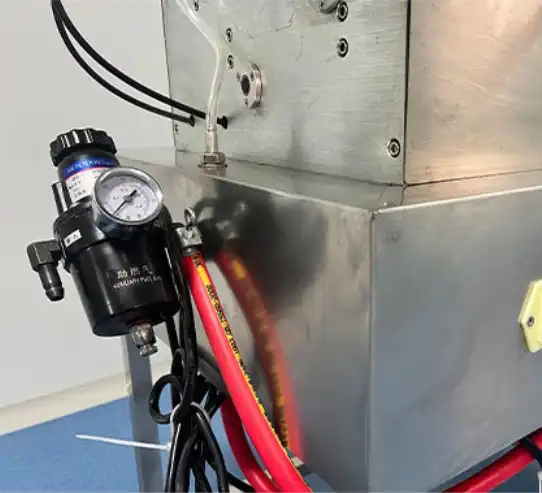

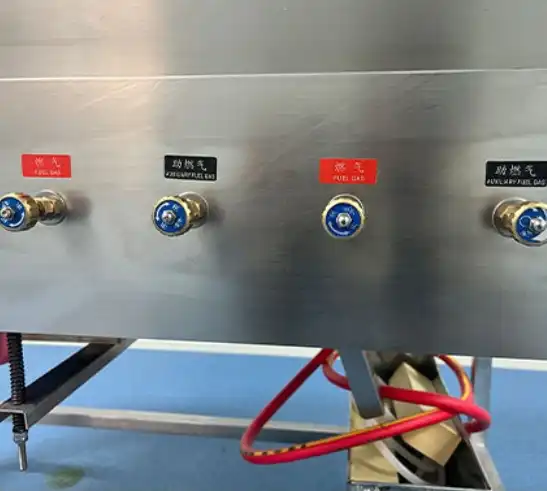

| Sealing gas | a. Gas+oxygen b. Liquefied gas+oxygen |

| Dimensions | 1850*1500*1350 mm |

| Weight | 400 kg |

Key Features That Make the Difference

Because of its exceptional adaptability, our ampoule filling apparatus distinguishes out. The machine is versatile enough to handle a wide range of product lines, since it can handle bottles that are 60-70mm in diameter. Within this range, you can use the same equipment for containers of varying sizes.

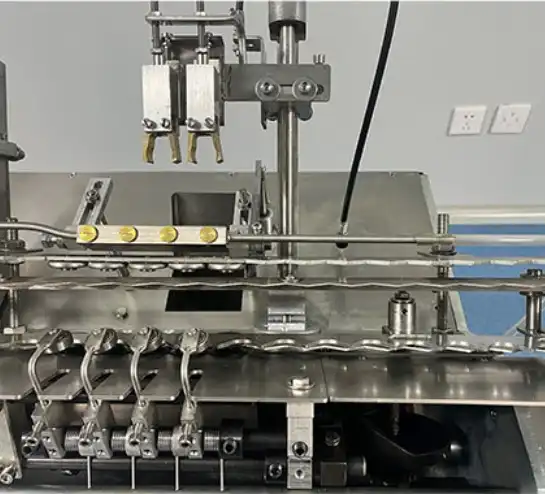

Efficiency is maximized by the eight-head design. The heads work separately to maintain constant fill volumes. This layout lessens the need for repairs and downtime. Thanks to the user-friendly interface and streamlined operation, your production crew will be quite satisfied.

Quality construction meets GMP standards throughout. Every component undergoes rigorous testing before assembly. The stainless steel construction resists corrosion and ensures easy cleaning. You can maintain sterile conditions effortlessly.

Perfect Applications for Multiple Industries

This versatile machine serves various sectors effectively. Pharmaceutical manufacturers rely on it for injectable medications and vaccines. Health product companies use it for liquid supplements and vitamins. Food factories appreciate its precision for liquid products.

Hospital preparation rooms benefit from smaller batch capabilities. Chemical plants find it ideal for precise liquid handling. The machine adapts to different viscosities and product types seamlessly.

Your production requirements determine the optimal setup. The flexible design accommodates various production schedules and volumes. Whether you're running continuous operations or batch production, this equipment delivers consistent results.

Application Areas

Technical Excellence You Can Trust

Precision engineering defines every aspect of this 8 head ampoule filling machine. The filling mechanism ensures accurate volumes every time. Advanced sensors monitor each operation cycle. Automatic adjustments maintain consistency throughout long production runs.

The control system offers intuitive operation. Your operators can quickly learn the functions and adjustments. Clear displays show all operational parameters. Emergency stops ensure operator safety at all times.

Maintenance requirements stay minimal thanks to robust construction. Regular cleaning procedures are straightforward. Replacement parts are readily available when needed. The machine design allows easy access to all components.

Production Process

Complete Support Package

When you choose our equipment, you receive comprehensive support. Our experienced technical team provides installation assistance. On-site commissioning ensures optimal performance from day one. Training helps your operators maximize efficiency.

We include FAT testing and certification documentation. This proves your machine meets all specified requirements. GMP compliance certification supports your quality management system. Wooden box export packaging protects your investment during shipping.

Free spare parts come with your purchase for the first year. This coverage includes commonly replaced components. Fast delivery ensures minimal downtime if replacement becomes necessary. Our global network supports customers worldwide.

Quality Control

Quality Assurance and Standards

Pharmaceutical-grade quality is assured by GMP certification. Prior to distribution, each product is subjected to comprehensive testing. Consistent performance across all units is ensured via quality control measures.

Understanding the ins and outs of international commerce legislation is a huge assistance. We are familiar with the needs of various markets. Your demands for regulatory compliance can be met with the help of documentation packages. Particular geographical needs are met by tailor-made setups.

Quality is of the utmost importance at our factory. Ongoing compliance is confirmed by regular audits. Product dependability is improved by ongoing quality improvement initiatives. Design revisions and adjustments are driven by customer input.

Global Partnership Approach

Relationships with consumers all across the globe are built by Factop. We have worked with clients from all over the world, including the US, EU, SA, Korea, the Philippines, and Indonesia. We are sensitive to cultural and commercial diversity.

Professional teams speak multiple languages fluently. This ensures clear communication throughout your project. International trade expertise simplifies complex procedures. Market knowledge helps identify optimal solutions for your specific needs.

Packaging and Transportation

Contact Us

Ready to enhance your production capabilities? Contact michelle@factopintl.com to discuss your specific requirements and discover how our 8 head ampoule filling machine can transform your manufacturing process.