Vitamin tablet press

Model: THDP-6

Tablet diameter: 5-18mm

Suitable: Food factory, vitamin, nutrition and supplement factory

Stock: In stock

Certificate: CE, GMP, ISO9001

Vitamin Tablet Press: Professional Manufacturing Solution for Your Production Needs

Are you looking for a reliable Vitamin tablet press to enhance your production capabilities? Our THDP-6 model delivers exceptional performance for vitamin and supplement manufacturing. This advanced machine ensures consistent tablet quality while meeting strict industry standards. Whether you operate a pharmaceutical factory, health product facility, or supplement production line, our product provides the precision and reliability you need for successful operations.

Main Parameter

| Specification | Details |

|---|---|

| Model | THP-6T Vitamin Tablet Press |

| Max. Tablet Pressure | 60 kN |

| Max. Tablet Diameter | 30 mm |

| Max. Tablet Thickness | 13 mm |

| Production Capacity | 3000 tablets/hour |

| Motor Power | 2.2 kW |

| Weight | 350 kg |

| Dimension | 700*650*1610mm |

Why Choose Our Tablet Press Technology?

Manufacturing high-quality vitamin tablets requires precision engineering and reliable equipment. Our candy produce machine model THDP-6 offers versatile tablet diameter options from 5-18mm, making it perfect for various vitamin formulations.

You'll appreciate the robust construction that ensures consistent tablet compression. The machine handles different powder compositions effectively. This means better production efficiency for your facility.

Our equipment meets international manufacturing standards. You get peace of mind knowing your production complies with regulatory requirements. The design focuses on ease of operation and maintenance.

Advanced Features for Modern Production

The THDP-6 model incorporates cutting-edge technology for optimal performance. You can adjust compression settings to match your specific vitamin formulations. This flexibility allows you to produce different tablet sizes and densities.

Temperature control systems maintain optimal operating conditions. Consistent pressure distribution ensures uniform tablet quality. These features reduce waste and improve your overall production efficiency.

Safety mechanisms protect both operators and equipment. Emergency stop functions and protective barriers create a secure working environment. You can focus on production knowing safety standards are maintained.

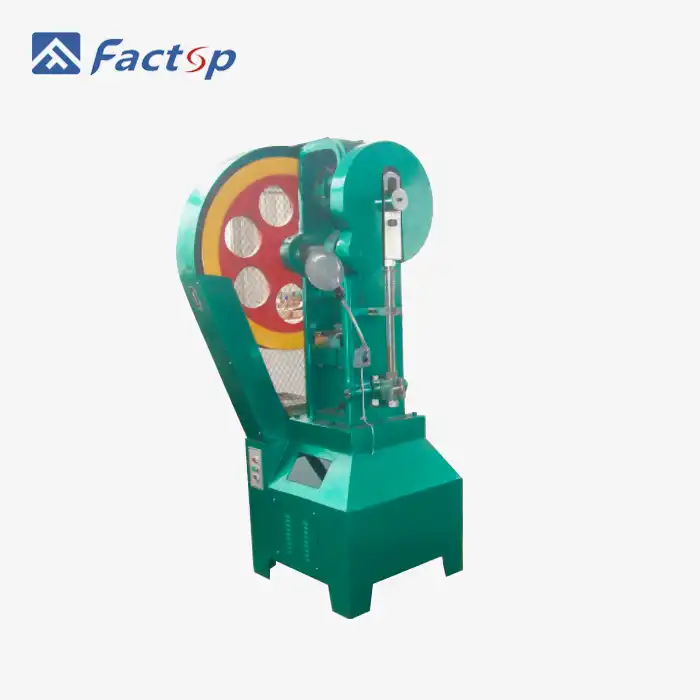

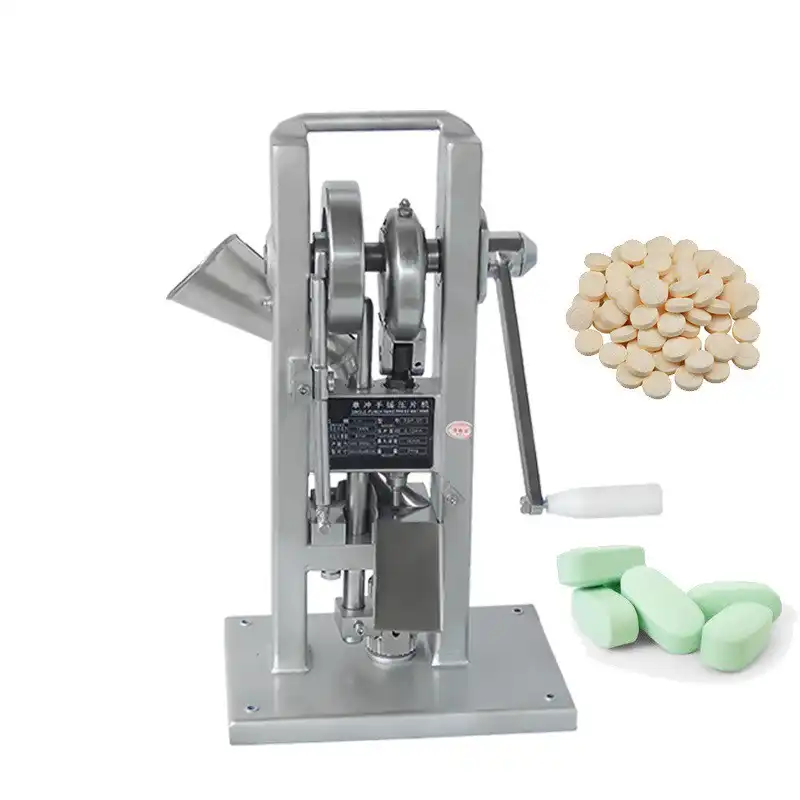

Real Photos Show

Perfect Applications Across Industries

This vitamin tablet press serves multiple industry sectors effectively. Food factories benefit from its versatile design and reliable operation. Nutrition and supplement manufacturers appreciate the consistent quality output.

Hospital preparation rooms find the compact design ideal for smaller batch production. Chemical plants utilize the robust construction for various tablet manufacturing needs. The equipment adapts to different production requirements seamlessly.

Research facilities and development laboratories also benefit from this technology. You can test new formulations and scale up production confidently. The machine supports both small-scale testing and commercial production.

Application Areas

Quality Assurance and Compliance

Our manufacturing facility maintains GMP certification standards. This ensures every machine meets pharmaceutical industry requirements. You receive equipment that complies with international quality standards.

CE certification demonstrates European safety compliance. ISO9001 certification reflects our commitment to quality management systems. These certifications provide assurance for your investment.

Qualification Certification

Wooden box export packaging protects your equipment during shipping. FAT testing and certification support guarantee proper functionality. You receive complete documentation for regulatory compliance.

Comprehensive Support Services

We provide on-site installation and commissioning support for your convenience. Our technical team ensures proper setup and operator training. This minimizes downtime and accelerates production startup.

Free spare parts coverage for one year protects your investment. Our proven technical team offers ongoing support throughout the equipment lifecycle. Fast delivery ensures minimal waiting time for your new equipment.

Multilingual support staff understand international trade requirements. We work with customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. This global experience benefits your project success.

Production Process

Ready Stock and Fast Delivery

The THDP-6 model maintains in-stock availability for immediate shipping. You don't need to wait for manufacturing lead times. Fast delivery gets your production line operational quickly.

Our inventory management ensures consistent equipment availability. Quality control processes verify each machine before shipment. You receive tested and certified equipment ready for installation.

Company Profile

Contact Us

Transform your vitamin manufacturing capabilities with our reliable Vitamin tablet press technology. Contact our experienced team at michelle@factopintl.com to discuss your specific requirements and receive detailed technical specifications for optimal production success.