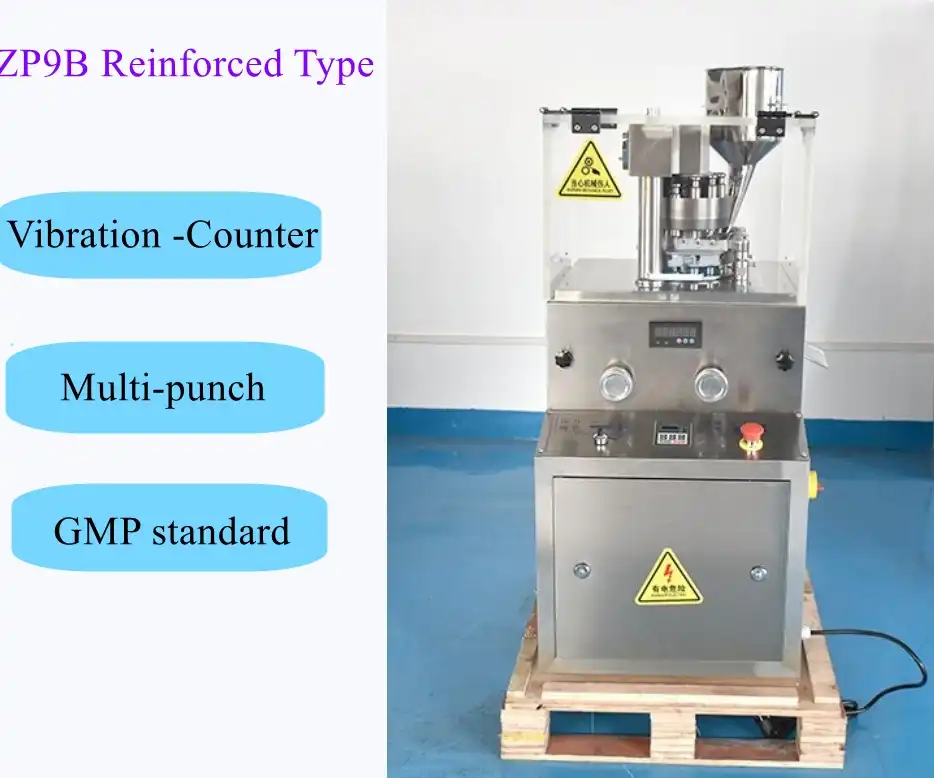

ZP-9 Rotary Tablet Press Machine

Max production capacity: 16200pcs/hour

Suitable: Pharmaceutical, lab, chemical, nutrition & supplements

Max tablet diameter: 20mm

Weight: 220kg

Dimension: 650*480*1020mm

ZP-9 Rotary Tablet Press Machine: Precision Manufacturing for Your Production Needs

Looking for reliable tablet production equipment? The ZP-9 Rotary Tablet Press Machine delivers exceptional performance for pharmaceutical, laboratory, chemical, and supplement manufacturing. This small but strong machine can turn your raw materials into tablets that are always the same quality and shape. This rotating tablet press machine gives you the accuracy and dependability you need to make professional tablets, whether you're running a small lab or adding to your production line.

Zp9 Rotary Tablet Press Introduction

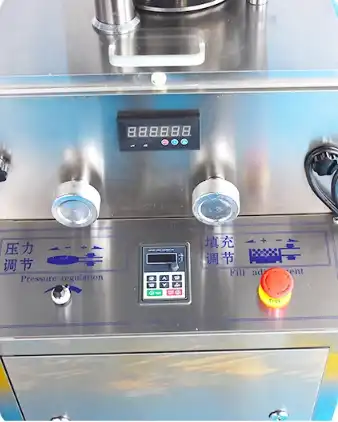

Product Specifications

| Feature | Specification |

|---|---|

| Model | ZP9B Enforced Rotary Tablet Press |

| Max. Pressure | 80 kN |

| Max. Tablet Diameter | 20 mm |

| Max. Depth of Fill | 15 mm |

| Production Speed | 16200 tablets/hour |

| Motor Power | 2.2 kW |

| Tablet Shape | Round, Customizable |

| Weight | 220 kg |

| Dimensions | 620*480*1020 mm |

Superior Performance Specifications

The ZP-9 rotary tablet press has great production features that make it suitable for a wide range of industrial needs. With a production rate of up to 16,200 pieces per hour, you can get a lot done without sacrificing quality.

Key specifications include:

- Maximum tablet diameter: 20mm for versatile tablet sizes

- Compact dimensions: 650×480×1020mm fits most production spaces

- Lightweight design: 220kg for easy installation and relocation

- Multi-industry compatibility: Pharmaceutical, laboratory, chemical, and nutrition applications

This machine handles various tablet formulations efficiently. You can produce tablets for different applications while maintaining consistent results across batches.

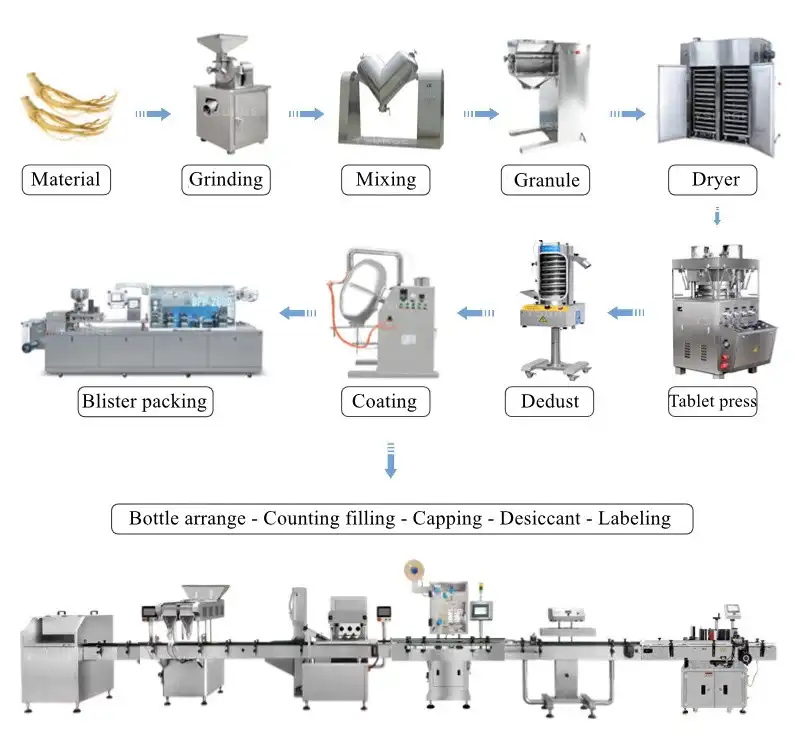

Production Process

Versatile Applications Across Industries

Your manufacturing needs vary depending on your industry. This tablet press machine adapts to multiple sectors seamlessly.

- Pharmaceutical Applications: Make sure that the medicine pills you make meet strict quality standards. The machine makes sure that pharmaceutical-grade goods are compressed properly and that the weight is spread out evenly.

- Laboratory Use: Perfect for research and development projects requiring small to medium batch production. You can test formulations and create samples with professional results.

- Nutritional Supplements: Manufacture vitamin tablets, mineral supplements, and health products with consistent quality. The machine handles various supplement formulations effectively.

- Chemical Industry: Produce chemical tablets for industrial applications. The robust construction withstands demanding production environments.

Application Areas

Quality Manufacturing Standards

Factop International Trade Company maintains strict quality standards throughout the manufacturing process. Our GMP-certified factory ensures every ZP-9 Rotary Tablet Press Machine meets international quality requirements.

You receive comprehensive support with your purchase:

- Free spare parts for one year after purchase

- FAT testing and certification support

- Professional wooden box packaging for secure international shipping

- On-site installation and commissioning services available

Our skilled expert team provides ongoing help to make sure that the machines work at their best. We know how important it is for your business process to have solid tools.

Quality Control

Expert Support and Service

Working with international clients requires expertise in global trade practices. Our professional team speaks multiple languages and understands international trade procedures. This expertise ensures smooth transactions and reliable communication throughout your purchase process.

We've formed relationships with clients in the United States, Europe, South Africa, Korea, the Philippines, and Indonesia. These partnerships show that we care about making our customers happy and providing effective service.

Fast delivery options minimize downtime in your production schedule. Our efficient logistics network ensures timely equipment delivery to your facility.

Packaging and Transportation

Technical Excellence and Innovation

The rotary design makes it possible to consistently crush tablets at different places. This technology keeps production speeds high while making sure that all tablets are of the same quality. You get the benefits of tech that has been used before and always works.

The machine's small size makes the most of the space on your factory floor. Even though it's small, the product works just as well as bigger industrial units for professionals.

Easy operation and maintenance reduce training time for your staff. The intuitive design allows operators to achieve optimal results quickly while minimizing maintenance requirements.

Our Wearhouse Show

Contact Us

Choosing the right tablet press equipment impacts your long-term production success. This machine provides the foundation for consistent, quality tablet production that grows with your business needs.

Our commitment to integrity, innovation, cooperation, and mutual success drives every customer relationship. We're dedicated to providing equipment that creates lasting value for your operations.

Ready to enhance your tablet production capabilities? Contact michelle@factopintl.com to discuss how the ZP-9 Rotary Tablet Press Machine can meet your specific manufacturing requirements and drive your business forward.

YOU MAY LIKE