Capsule pill filling machine

Model: NF600

Suitable: #00 - #4 gelatin, HPMC

Applicable: Powder, granules, pills, liquid

Stock: In stock

Capsule Pill Filling Machine: Professional Solution for Your Production Needs

Are you looking for a reliable capsule pill filling machine to streamline your pharmaceutical production? Excellent performance is provided by our NF600 Hardgelatin Capsule Liquid Sealing Machine to factories all over the world. This sophisticated machine can handle capsules from #00 to #4. It can also work with HPMC capsules. This equipment can easily handle mixing powders, grains, pills, or liquids, depending on your production needs.

Why Choose Our Capsule Filling Equipment?

Versatile Capsule Compatibility

Our machine accommodates various capsule sizes and materials. You can work with standard gelatin capsules or modern HPMC alternatives. This flexibility allows you to adapt to different product specifications without changing equipment.

Multiple Material Handling

The NF600 processes different material types seamlessly. Powder formulations flow smoothly through the filling mechanism. Granulated materials maintain their integrity during processing. Small pills transfer accurately into capsules. Liquid formulations seal properly without leakage.

Professional Manufacturing Standards

This equipment is made by Factop in a building that is GMP-certified. Before it is sent out, every machine goes through a lot of quality checks. Every unit comes with a FAT (Factory Acceptance Testing) certificate. This makes sure that it will work reliably from the first day it is used.

Product Benefits

Specifications

| Feature | Description |

|---|---|

| Name | Liquid capsule pillfilling machine |

| Output Capacity | 36000 capsules per hour |

| Power | 9kw |

| Filling Accuracy | ±2% |

| Machine Dimensions | 3800*900*1900mm |

| Power Supply | 220V/380V, 50Hz/60Hz |

| Suitable | Oil, liquid, mixing liquid |

| Automation Level | Fully automatic |

| Control System | PLC Control with Touchscreen |

Technical Excellence You Can Trust

Proven Engineering Design

Our experienced technical team designs each component for optimal performance. Years of pharmaceutical machinery expertise guide every engineering decision. The result is equipment that delivers consistent results in demanding production environments.

Quality Construction

Robust materials ensure long-term durability. Precision manufacturing creates smooth operation cycles. Easy-access components simplify routine maintenance tasks. These design elements minimize downtime and maximize productivity.

International Compliance

The machine meets international pharmaceutical manufacturing standards. Wooden box export packaging protects your investment during shipping. Complete documentation supports regulatory compliance in your facility.

Comprehensive Support Services

Installation and Training

On-site installation service ensures proper setup. Our technicians provide comprehensive training for your operators. This hands-on approach guarantees smooth integration into your production line.

Warranty Protection

Free spare parts come included for one full year after purchase. This coverage protects your investment and maintains production continuity. Quick delivery of replacement parts minimizes any potential delays.

Global Service Network

Factop serves customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our international experience helps us understand diverse market requirements. Local support ensures responsive service wherever you operate.

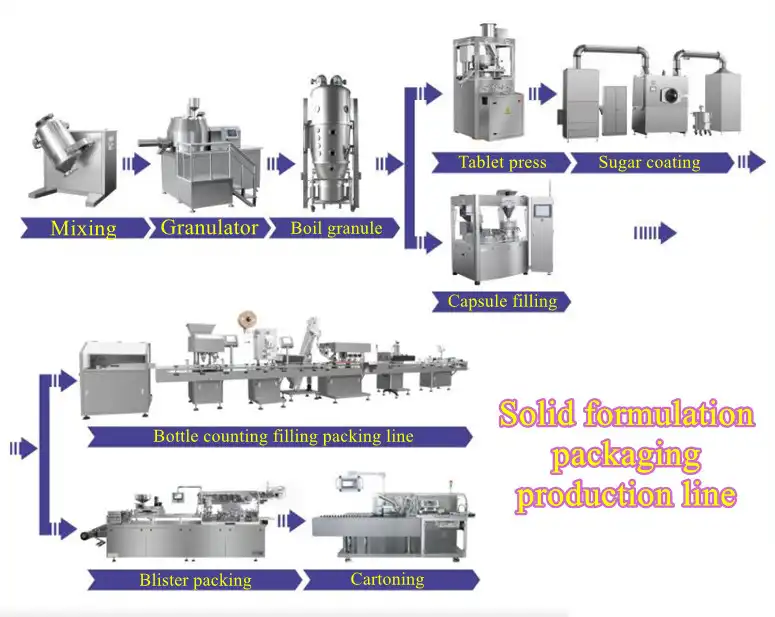

Production Process

Applications Across Industries

Pharmaceutical Manufacturing

Large-scale pharmaceutical companies rely on our equipment for consistent production. The capsule pill filling machine integrates seamlessly into existing production lines. Strict quality controls ensure pharmaceutical-grade output every time.

Health Product Facilities

Supplement manufacturers appreciate the machine's versatility. Different capsule sizes accommodate various product formulations. Consistent filling accuracy maintains product quality standards.

Hospital Preparation Rooms

Smaller-scale operations benefit from the machine's efficiency. Easy operation suits facilities with limited technical staff. Reliable performance supports critical patient care requirements.

Food and Chemical Applications

Beyond pharmaceuticals, the machine serves food supplement and chemical industries. Versatile material handling adapts to different product characteristics. Clean design principles ensure product purity across applications.

Smart Investment for Your Business

Immediate Availability

The NF600 model is currently in stock for immediate shipment. Fast delivery gets your production running quickly. No waiting periods delay your manufacturing schedule.

Cost-Effective Operation

Efficient design minimizes energy consumption during operation. Reliable construction reduces maintenance costs over time. High-speed processing increases overall productivity and profitability.

Future-Ready Technology

Modern engineering ensures compatibility with evolving industry standards. Upgradeable components extend equipment lifespan. This forward-thinking approach protects your long-term investment.

Product Photos Show

Partner with Industry Leaders

Factop's commitment to "integrity, innovation, cooperation, and win-win" guides every customer relationship. Our multilingual team understands international business requirements. We're here to support your success in competitive global markets.

Our Workshop Show

Contact Us

Ready to enhance your production capabilities? Contact our team at michelle@factopintl.com to discuss how our capsule pill filling machine can meet your specific requirements. Let's build a successful partnership together.

YOU MAY LIKE