Pharmaceutical capsule filling machine

Material: Stainless steel

Certificates: ISO9001, CE, GMP

Package: Export wooden packing

Appearance: New type finished machine

Warranty time: 24 months

Pharmaceutical Capsule Filling Machine - Premium Quality Manufacturing Equipment

Looking for a reliable pharmaceutical capsule filling machine to enhance your production capabilities? You've come to the right place. When it comes to making medicines, we at Factop International Trade Company know how important accuracy and quality are. Our high-tech pill filler is the right mix of cutting-edge technology and strong engineering. This machine is built to meet the high standards of pharmaceutical companies, health product makers, and hospital prep rooms all over the world. You can trust that our equipment will give you reliable, high-quality results for your capsule production needs because it has worked well in foreign markets before.

Main Parameter

| Model | NJP-3800C Pharmaceutical Capsule Filling Machine |

| Production capacity | 228000pcs/hour |

| Machine weight | 2200kg |

| Dimension | 1395*1180*2260mm |

| Voltage | 220/380V 50HZ |

| Motor | 10.5kw |

| Holes number | 27 holes |

| Vacuum | -0.04 to -0.08MPa |

| Dust | 24.5Kpa, 210m3/h |

| Air compressure | 12m3/h, 0.3-0.4MPa |

| Noisy | 78dBA |

| Accuracy | Empty 99.99%, Full 99.98% |

| Suitable | 000#-5# |

| Filling accuracy | West-medicine 3%, Chines-medicine 4% |

| Filling type | Powder, granule, pellets, tablets |

Why Choose Our Capsule Filling Equipment?

When you buy one of our capsule filling options, you're getting equipment that meets the top standards in the business. Our machines are made with high-quality stainless steel, which makes them last a long time and meet strict cleanliness standards.

The equipment has a lot of different certificates, such as ISO9001, CE, and GMP approval. You can work with trust now that you know your products meet foreign quality standards. We made these tools so that they can work well in a number of different businesses.

Our 24-month guarantee covers your purchase and keeps it safe. This wider reach shows that we're sure of the quality and dependability of our products. We also give you free replacement parts for the first year after you buy from us, which keeps your operating costs low.

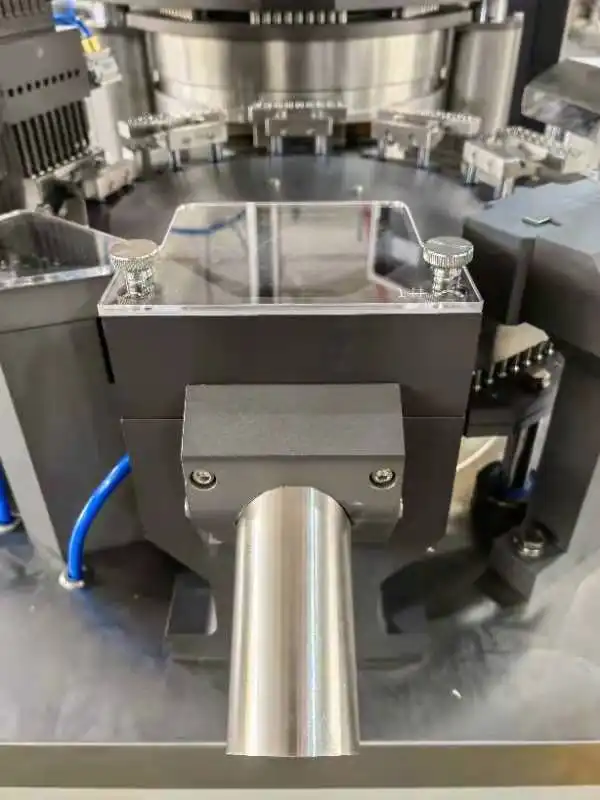

Advanced Features and Specifications

Our pill filler uses cutting edge technology to make sure that the filling process is precise. The stainless steel design makes the machine very resistant to rust and wear, which greatly extends its useful life.

The new finished machine design is more efficient and easier for people to use. Every part has been carefully designed to keep working the same way over long production runs. This care for detail means that your business will have less downtime and be more productive.

Export wooden packaging ensures your equipment arrives in perfect condition, regardless of shipping distance. We understand the importance of protecting your investment during transportation, which is why we use only the highest quality packaging materials.

Packaging and Transportation

Comprehensive Support Services

Our dedication to your success goes far beyond the buy itself. We help with FAT (Factory Acceptance Testing) approval, which makes sure that your equipment meets all the standards before it is sent to you. You can feel safe and sure about your investment after this thorough testing process.

You can get help with installation and testing on-site to make sure the connection goes smoothly with your current production line. Our skilled expert team can help you through the whole setup process so that it doesn't get in the way of your business.

We maintain an experienced professional team proficient in multiple foreign languages. This capability ensures clear communication throughout your purchasing journey and ongoing support relationship. Our team understands international trade procedures and can navigate complex requirements efficiently.

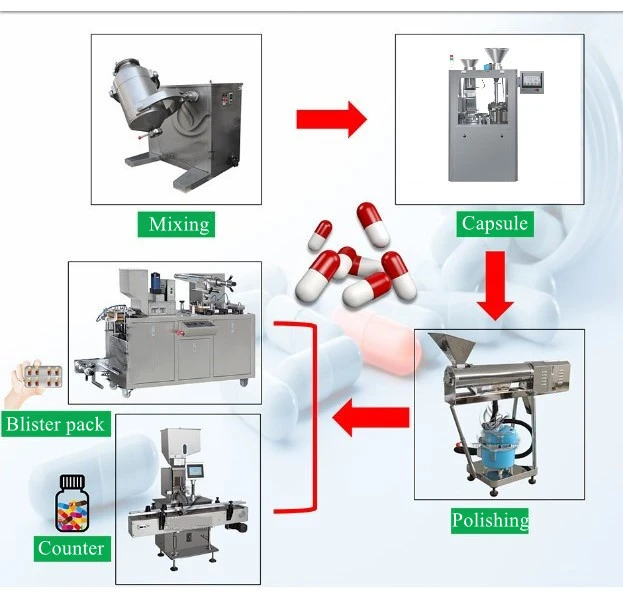

Production Process

Global Reach and Proven Success

Factop has established strong partnerships with customers across multiple continents. Our equipment operates successfully in America, Europe, South Africa, Korea, Philippines, Indonesia, and many other regions. This global presence demonstrates the versatility and reliability of our manufacturing solutions.

Our pharmaceutical capsule filling machine serves diverse applications including pharmaceutical factories, health product facilities, hospital preparation rooms, food factories, and chemical plants. This versatility makes our equipment an excellent choice for various production requirements.

By following GMP standards throughout the whole manufacturing process, we make sure that every machine we use meets the strict needs of making medicines. The best quality standards are kept at our GMP-certified plant, so you can be sure that your tools will work right and follow the rules.

Application Areas

Technical Excellence and Innovation

The tech team at Factop works on all projects with years of knowledge and experience. We make equipment that goes above and beyond what the industry expects by combining tried-and-true technical concepts with new ways of designing things.

The result of a lot of study and development work is our offering. Performance, dependability, and ease of upkeep have been taken into account in every part of the design. This careful attention to detail makes sure that you get the most out of your investment.

Fast delivery capabilities mean you can integrate new equipment into your production schedule quickly. We understand the importance of minimizing lead times and work diligently to meet your project timelines.

Quality Control

Your Partner for Future Growth

Choosing Factop means partnering with a company committed to your long-term success. We believe in building lasting relationships based on integrity, innovation, cooperation, and mutual benefit. Our business philosophy drives us to continuously improve our products and services.

After-Sales Service

Contact Us

Ready to enhance your production capabilities with our premium pharmaceutical capsule filling machine? Contact our expert team at michelle@factopintl.com to discuss your specific requirements and discover how we can support your manufacturing goals.

YOU MAY LIKE