Size 2 capsule filling machine

Capacity: 12000pcs/hour

Weight: 700kg

Dimension: 1000*700*1900mm

Stock: In stock

Certificate: CE, GMP, ISO9001

Size 2 Capsule Filling Machine - Professional Pharmaceutical Equipment

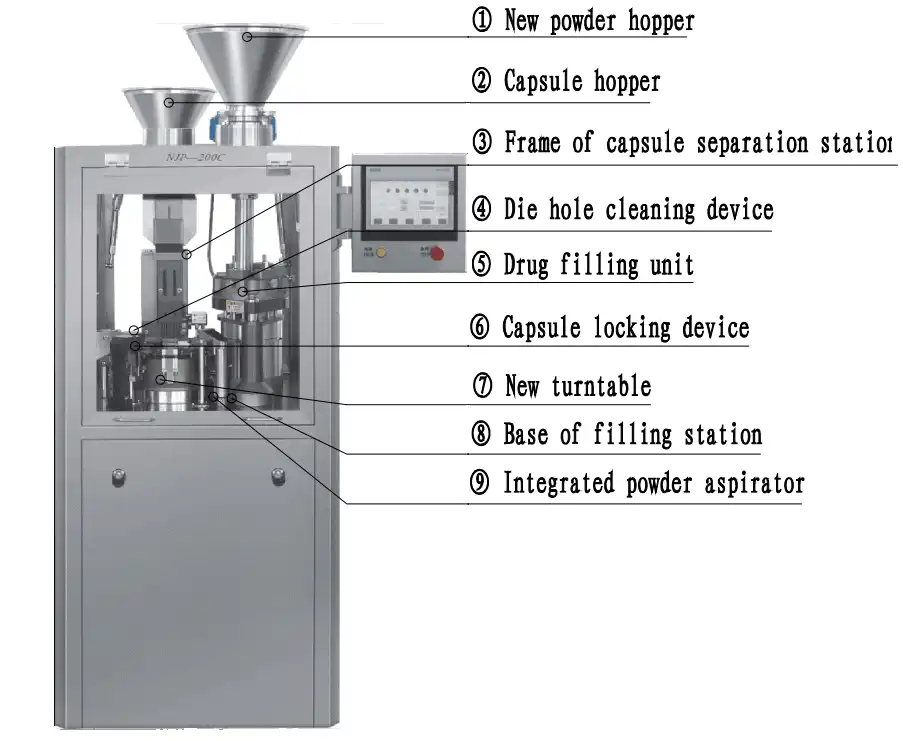

Looking for a reliable Size 2 capsule filling machine that delivers consistent results? You've found the perfect solution. Precision engineering and easy-to-use operation are combined in our NJP-200C capsule filling apparatus. This machine is designed especially to handle Size 2 capsules quickly and accurately. This technology will greatly increase your productivity and simplify your manufacturing process, whether you're operating a hospital preparation room, pharmaceutical plant, or health product facility.

Capsule Filling Machine Main Parameter:

|

Model |

NJP-200 |

NJP-400 |

NJP-800 |

NJP-1200 |

|

Production capacity |

12000pcs/h |

24000pcs/h |

48000pcs/h |

72000pcs/h |

|

Machine weight |

600kg |

600kg |

900kg |

1100kg |

|

Dimension |

1000*710*1900mm |

1000*710*1900mm |

1050*960*1900mm |

1050*980*1900mm |

|

Voltage |

110/220/380V 50HZ |

|||

|

Motor |

Engine 1.1kw, pump 0.75kw, dust 1.1W |

Engine 1.5kw, pump 2.2kw, dust 2.2w |

||

|

Hole |

2 hole |

3 hole |

6 hole |

9 hole |

|

Pump |

20m3/h-0.04-0.08Mpa |

40m3/h-0.04-0.08Mpa |

||

|

Dust |

17.6Kpa 180m3/h |

17.6Kpa 180m3/h |

24.5Kpa 210m3/h |

|

|

Accuracy |

Empty 99.99%, Full 99.95% |

|||

|

Suit capsule size |

#00B, 00, 0, 1, 2, 3, 4, 5 |

|||

|

Suit filling range |

Powder, granules, pellets, tablets |

|||

Why Choose Our Size 2 Capsule Filling Equipment?

High-Performance Specifications

With a 12,000 piece per hour capability, our NJP-200C model performs well. With a weight of 700 kg and dimensions of 1000 x 700 x 1900 mm, this powerful machine is small enough for the majority of industrial facilities while yet being sturdy.

The machine features advanced dosing systems that ensure uniform filling every time. You'll appreciate the precise weight control and minimal powder waste. The stainless steel construction meets strict hygiene standards required in pharmaceutical manufacturing.

GMP Certified Quality

Internationally certified equipment is required for your manufacturing plant. Our product is certified by ISO9001, GMP, and CE. Purchasing equipment that conforms with international pharmaceutical production standards is ensured by these certificates.

The GMP certification is particularly important for pharmaceutical applications. It ensures that your capsule filling process maintains the highest quality standards from start to finish.

Key Features and Benefits

User-Friendly Operation

Operating this machine is straightforward, even for new team members. The intuitive control panel allows you to adjust filling parameters quickly. You can easily switch between different powder formulations without complex setup procedures.

The transparent safety guards let you monitor the filling process while maintaining operator safety. Emergency stop buttons are strategically placed for immediate access when needed.

Versatile Applications

This equipment serves multiple industries effectively:

- Pharmaceutical factories producing medications

- Health product manufacturers creating supplements

- Hospital preparation rooms for custom formulations

- Food factories processing nutritional products

- Chemical plants handling powder materials

Reliable Construction

This machine's precision-machined components provide reliable operation every day. The equipment's lifetime is increased and maintenance needs are reduced thanks to its sturdy design.

Quality bearings and motors ensure smooth operation even during extended production runs. You'll experience minimal downtime and maximum productivity.

Complete Support Package

Professional Installation

On-site installation and commissioning assistance is offered by our expert staff. We make sure your computer runs as efficiently as possible right out of the box. Operator training and extensive testing are part of the installation procedure.

Quality Assurance

Every machine undergoes rigorous FAT (Factory Acceptance Testing) before shipment. This testing verifies all functions and performance parameters meet specifications. You receive detailed test reports with your equipment.

Warranty Protection

Your investment in the Size 2 capsule filling machine is protected with free spare parts for one year after purchase. This warranty covers manufacturing defects and normal wear components. Our responsive service team ensures minimal production interruptions.

Machine Real Photos

Technical Excellence

Advanced Dosing Technology

The precision dosing system efficiently manages a range of powder properties. The machine maintains constant fill weights whether you're dealing with granular or fine powders. Efficiency is increased and human intervention is decreased with automatic weight adjustment.

Easy Maintenance

Designed for easy cleaning and maintenance, the machine features quick-release components. Tool-free disassembly speeds up changeover times between products. This design philosophy reduces operational costs and increases productivity.

Production Process

Global Reach and Experience

Factop International Trade Company has established partnerships across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our international experience ensures we understand diverse regulatory requirements and market needs.

Our multilingual technical team provides support in your preferred language. This communication advantage eliminates misunderstandings and ensures smooth project execution.

Packaging and Transportation

Our Cooperation Cases from Customers

Contact Us

Investing in our Size 2 capsule filling machine means choosing proven technology backed by comprehensive support. The NJP-200C model is currently in stock and ready for immediate shipment.

Our wooden box export packaging protects your investment during international shipping. All necessary documentation and certificates accompany each shipment for smooth customs clearance.

Ready to discuss your specific requirements? Contact our team at michelle@factopintl.com for detailed quotations and technical specifications. We're here to help you select the perfect capsule filling solution for your production needs.

YOU MAY LIKE