Bottle cartoning machine

Working type: Fully automatic

Suitable: Pharmaceutical, food, chemical

Brand: Factop

Material: Stainless steel 304/316

Bottle Cartoning Machine - Professional Packaging Solution for Your Production Line

Looking for a reliable packaging solution for your bottles? For the pharmaceutical, food, and chemical sectors, our Bottle cartoning machine performs exceptionally well. Your packing procedure will be streamlined with this completely automated system while upholding the highest standards of quality. Our equipment is built to last and satisfies stringent industry standards thanks to its quality stainless steel 304/316 construction. The way this cutting-edge technology improves your production efficiency and lowers the cost of manual labor will be appreciated.

Product Specifications

| Feature | Description |

|---|---|

| Model | 130 type Automatic Bottle Cartoning Machine |

| Speed | Up to 120 cartons per minute |

| Capacity | 1-6 bottles per carton |

| Power Supply | 220V/50Hz |

| Air Consumption | 0.6 m³/min |

| Machine Dimensions | 3400*1200*1800mm |

| Weight | 1300kg |

| Materials Supported | Plastic, Glass Bottles, Metal Containers |

| Certifications | ISO9001:2015, CE, GMP |

Key Features and Benefits

Robust Construction

Our equipment is built with high-quality stainless steel that can survive harsh industrial settings. Excellent corrosion resistance and ease of cleaning are guaranteed by the 304/316 grade steel. Your production line's long-term dependability is ensured by this design decision.

Versatile Application

Whether you're packaging pharmaceuticals, food products, or chemicals, this machine adapts to your needs. The flexible design accommodates various bottle sizes and carton dimensions. You can easily switch between different products without extensive reconfiguration.

Fully Automatic Operation

The system operates with minimal human intervention. Simply load your bottles and cartons, then let the machine handle the rest. This automation reduces labor costs and minimizes packaging errors.

Application Areas

Technical Specifications

The machine incorporates advanced technology for precise bottle placement and carton sealing. Its user-friendly control panel allows easy operation and monitoring. The compact design fits seamlessly into existing production lines without requiring extensive floor space modifications.

Speed and accuracy define this equipment's performance. You'll notice improved throughput compared to manual packaging methods. The consistent packaging quality helps maintain your brand's professional image.

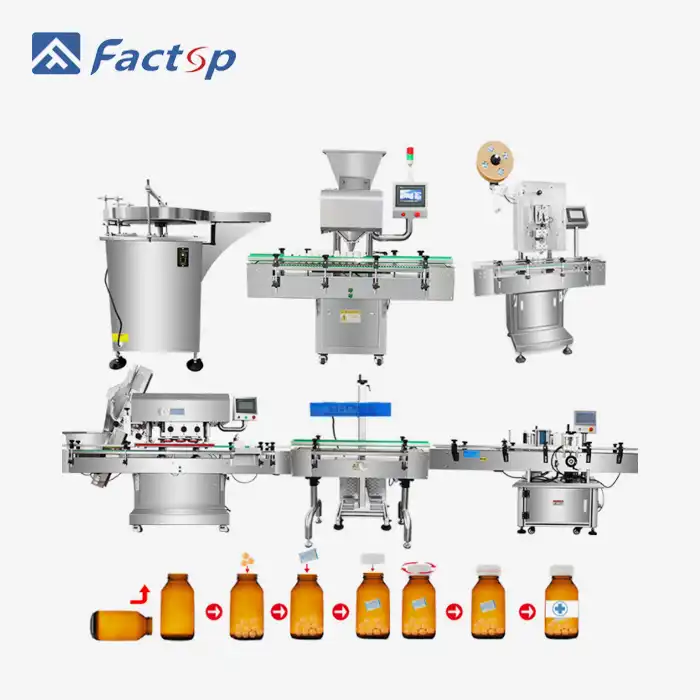

Our bottle cartoning machine show:

Industries We Serve

Pharmaceutical Manufacturing

Pharmaceutical companies trust our equipment for critical packaging operations. The machine meets GMP standards, ensuring compliance with regulatory requirements. Your sterile products remain protected throughout the packaging process.

Food Processing

Food manufacturers benefit from the hygienic design and easy cleaning features. The stainless steel construction prevents contamination and maintains food safety standards. Your products reach consumers in perfect condition.

Chemical Industry

Protected wrapping is needed for chemical goods, and our machine provides reliable containment. Multiple chemical mixtures can be safely handled by the strong structure. Packing everything from cleaning supplies to poisons used in factories is possible.

Our bottle cartoning machine details show:

Why Choose Factop?

Manufacturing Excellence

When it comes to manufacturing pharmaceutical gear, Factop has a wealth of experience. Bottle cartoning machine packaging equipment design has special obstacles, which our team is aware of. We've come up with answers to problems that arise in actual manufacturing.

Global Reach

We serve customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. This international experience helps us understand diverse market requirements. Your specific regional needs receive proper attention.

Comprehensive Support

Our multilingual team provides excellent customer service throughout your purchase journey. We offer technical support, installation guidance, and training services. You're never alone when working with Factop equipment.

Our Machine Packaging Show

Quality Assurance

Every machine undergoes rigorous testing before shipment. FAT (Factory Acceptance Testing) certification ensures your equipment meets specifications. We provide detailed documentation and performance reports for your records.

The GMP-certified manufacturing facility maintains strict quality control standards. Each component receives careful inspection during assembly. You receive equipment that performs reliably from day one.

Installation and Maintenance

Professional installation services ensure proper setup and commissioning. Our technicians provide on-site support to optimize machine performance. Training sessions help your operators maximize equipment efficiency.

Maintenance requirements remain minimal thanks to the robust design. We provide comprehensive manuals and spare parts availability. The first year includes free spare parts coverage for added peace of mind.

Our Workshop Show

Contact Us

Get ready to take your packing skills to the next level! For a personalized discussion about your needs, get in touch with our staff. Choose the optimal setup for your production requirements with our assistance. Extensive quotations and technical requirements are provided by our specialists.

The Bottle cartoning machine represents a smart investment in your production future. You'll appreciate the improved efficiency, reduced labor costs, and consistent packaging quality. This equipment pays for itself through enhanced productivity and reduced operational expenses.

Transform your packaging operations today with Factop's reliable cartoning solutions. Contact michelle@factopintl.com for detailed specifications and competitive pricing. Our team stands ready to support your success.

YOU MAY LIKE