One of the most crucial decisions in pharmaceutical and nutraceutical production is whether to use softgels or hard capsules. Both ways of encapsulation have different benefits for providing active ingredients. Softgels work best in liquids and help with bioavailability, but hard capsules are more flexible with powders and granules and are cheaper to make. Understanding these important differences helps makers meet strict quality standards and market demands while making sure that their products work well, that customers like them, and that production is efficient.

Understanding the Basics of Hard Capsules and Softgel Capsules

Capsules are different types of capsules mainly because of how they are made and what they are made of. Hard capsules are made of two pieces that fit together: a body, which is usually made of gelatin, and a cap, which is sometimes made of hydroxypropyl methylcellulose (HPMC), a plant-based substance. This two-piece design makes a hard shell that is great for holding dry materials like powders, pellets, granules, and even small pills.

Hard Capsule Construction and Materials

Today, hard capsules are made with new methods that make sure the wall thickness is the same and the size fits perfectly. Gelatin-based versions are great at showing clarity and dissolving quickly, but HPMC versions are better for vegetarians and resist moisture better. Capsules come in different sizes, from 000, the largest, to 5, the smallest. Depending on the density of the powder and how the recipe needs to be made, capsules can hold anywhere from 50 mg to 1,500 mg.

Softgel Capsule Design Principles

Softgel capsules are made in a single, seamless piece using rotating die encapsulation technology. The flexible gelatin or veggie shell is made around a liquid or semi-solid fill at the same time. This method makes a dosage form that is completely sealed. This keeps the product stable during its shelf life by stopping oxidation and leakage.

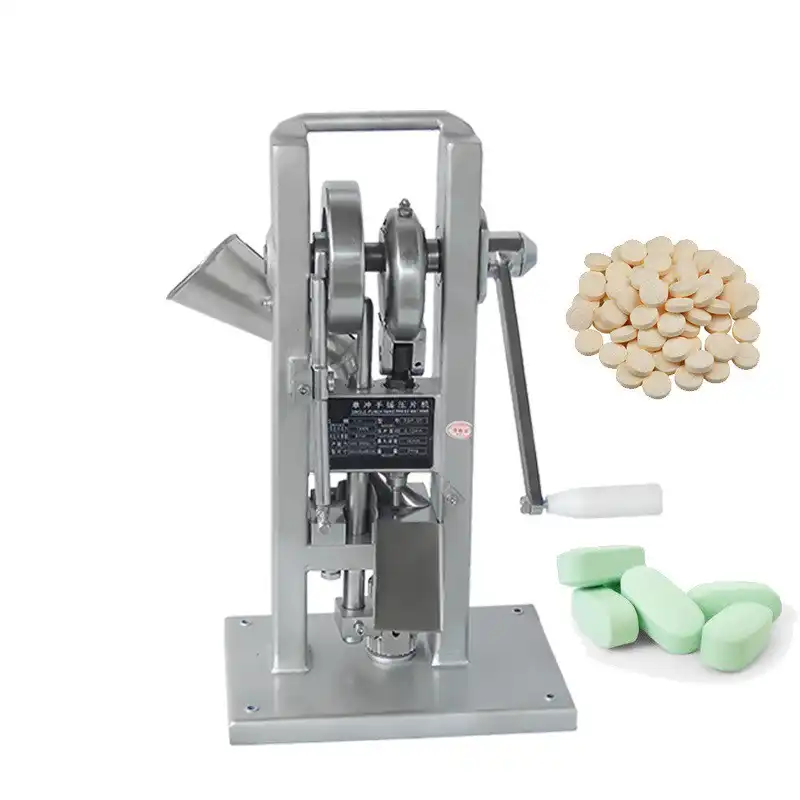

The different ways of packaging affect how much and what kind of equipment is needed for production. Hard capsules are made with filling tools that can deal with different kinds of powder and make products quickly. On the other hand, softgel manufacturing needs special equipment to make shells and fill them in one process.

Comparative Analysis: Hard Capsules vs Softgel Capsules

The way a capsule format performs affects its bioavailability, stability, and the way that it is made. These performance qualities change a lot from one format to another. This comparison study looks at important factors that affect both the success of the formulation and its ability to be sold.

Dissolution and Bioavailability Characteristics

Lipophilic chemicals usually have better bioavailability in softgels because the softgel's liquid inside and quick shell breakdown help the contents absorb better. Since the active ingredients are already dissolved, the step needed for solid preparations is not necessary. This leads to quicker absorption and more predictable pharmacokinetic profiles. Hard pills that contain powders need to dissolve before they can be absorbed by the body. This process can be improved by making the particles smaller, using substances that help with solubilization, and using better formulation methods.

Stability and Shelf Life Considerations

Different types of capsules have very different ways of protecting the environment. Softgels are great at keeping moisture and air out, so they're perfect for sensitive oils, vitamins, and plant extracts that can easily oxidize. Hard capsules are good enough to protect stable powders, but if the material inside absorbs water or if a longer shelf life is needed, extra moisture-proof packing may be needed.

Manufacturing Efficiency and Scalability

Things that have to do with production show that each style has its own clear benefits. Advanced models such as the HSR-200 with its 103×200 mm die roller setup and variable speed control show that high-speed capsule filling tools for hard capsules can exceed 86,400 pieces per hour. The machinery uses standard industrial power (AC380V 50HZ 7KW) and maintains precise filling through automation. The sealed shell design means that softgel production doesn't need extra packing and can run at slower speeds.

Benefits of Hard Capsules and Softgel Capsules for Pharmaceuticals and Nutraceuticals

Each way of packaging has its own benefits that are useful for different kinds of medicine and the needs of the market. Knowing these benefits helps people make smart choices about product creation and business success.

Hard Capsule Advantages in Modern Manufacturing

Hard pills are great for a wide range of formulation problems. The two-piece design can hold enteric-coated pellets, combination products, and modified-release formulas, which would not be possible with softgels. The ability to make different products extends to customization choices like clear, colored, or opaque shells that can be printed on for branding and identification.

Here are the main reasons why hard capsules are good for a lot of different uses:

- Cost-effectiveness for large-scale production with automatic filling equipment that has high throughput rates and makes very little waste

- Formulation flexibility that allows combination products, instant and controlled-release profiles, and the separation of ingredients that don't work well together in the same dosage form

- Quality control benefits through direct inspection, keeping an eye on weight changes, and simple ways of doing analytical tests

- Regulatory approval in places around the world that have well-known drug standards and a lot of safety data backing their registration applications

These benefits make it easier to produce more drugs while keeping quality high and costs low in a range of market groups.

Softgel Capsule Benefits for Specialized Applications

Softgels are great for uses that require better bioavailability, patient compliance, and ingredient protection. The seamless shell design gets rid of the taste and smell problems that come with liquids and allows for very exact dosing. For oil-based supplements, studies that ask people what they prefer have always shown that softgels are more popular than pills or hard capsules.

Procurement Insights and Decision-Making for Capsule Sourcing

Strategic sourcing choices affect the standard of the product, compliance with the rules, and the business's success. When choosing capsule suppliers and manufacturing partners, procurement workers need to think about a lot of different things.

Quality Standards and Certification Requirements

Suppliers with a wide range of certifications, such as GMP, ISO 9001, FDA registration, and CE marking, are needed for pharmaceutical-grade hard capsules. These licenses make sure that global markets always have the same level of quality, can track products back to their source, and follow the rules. Suppliers need to show that they have proven ways of making things, controlling the environment, and making sure quality that meets global standards for the pharmaceutical industry.

Supply Chain Reliability and Risk Management

Capsule sourcing methods need to make sure that supply continuity, geographic diversification, and vendor qualification standards are met. To keep the supply chain running smoothly, top suppliers offer a number of production sites, inventory management software, and technical help. Long-term relationships with certified suppliers allow for stable, customized, and quick service delivery.

When you buy things strategically in order to cut costs, you have to find a balance between price, quality, and service. Supplier partnerships, consolidated buying plans, and volume commitments can keep products reliable and of good quality while also cutting costs.

Practical Tips for Handling and Utilizing Hard and Softgel Capsules

Correct handling methods keep the quality of the product from when it is received to when it is finally packaged. Environmental controls, storage practices, and handling techniques have a direct effect on capsule integrity and finished product performance.

Storage and Environmental Control Requirements

To keep hard pills from soaking up moisture and damaging the shell, they need to be stored where the humidity level can be controlled (usually 35% to 65% RH). Keeping the temperature between 15 and 25 °C will keep the color and dimensions the same. During the production and storage phases, proper storage containers with moisture barrier features protect against changes in the environment.

Equipment Selection and Operation Optimization

Today's capsule fillers, like the HSR-200 type, have new features that help make production more efficient and improve the quality of hard capsules. The 1680x770x1800mm footprint of the equipment allows for the production of a large amount while keeping precise filling through variable speed control (0–6rpm) and automated monitoring systems. Regular maintenance plans and operator training programs make sure that equipment always works and downtime risks are low.

Quality control methods include testing materials when they arrive, monitoring the process, and checking the finished product. Dissolution testing, substance uniformity analysis, and microbiological testing together give full quality assurance that meets the needs of both customers and the law.

Conclusion

It depends on the needs of the formulation, bioavailability, and output on whether to use softgel or hard capsules. When you need better bioavailability and customer acceptance for a liquid formulation, softgels are a great choice. On the other hand, hard capsules are a cost-effective and flexible option for powder formulations. Each style has its own benefits that are useful for certain types of therapy and for meeting the needs of the market. Successful encapsulation methods take a close look at the product, the rules, and the commercial goals in order to get the best results for patients and the business.

FAQ

Q1: What fill weights can hard capsules accommodate compared to softgels?

A: Hard capsules can accommodate fill weights ranging from 50mg to 1500mg, depending on size and powder density, while softgels typically handle 100mg to 1000mg of liquid formulations due to shell thickness and sealing requirements.

Q2: How do dissolution times compare between hard capsules and softgels?

A: Softgels generally dissolve within 5-10 minutes due to their thin, flexible shells, while hard capsules typically require 10-30 minutes depending on shell material and fill characteristics, though both meet pharmacopeial dissolution requirements.

Q3: What are the main factors affecting capsule selection for new product development?

A: Key factors include ingredient compatibility, desired bioavailability, production volume requirements, cost considerations, and market preferences, with hard capsules offering advantages for powder formulations and softgels excelling for liquid applications.

Partner with Factop for Advanced Capsule Manufacturing Solutions

Selecting the right hard capsules manufacturer requires expertise, reliability, and comprehensive service capabilities. Factop machinery delivers cutting-edge capsule filling equipment designed for pharmaceutical and nutraceutical applications, backed by international certifications and proven performance records. Our HSR-200 capsule filling machine exemplifies innovation with its high-capacity output of 86,400 pieces per hour, precision die roller technology, and comprehensive safety certifications, including CE, GMP, FDA, and ISO9001 compliance.

Factop's commitment to excellence extends beyond equipment manufacturing to include technical support, training programs, and after-sales service, ensuring optimal production performance. Our multilingual team serves clients across America, Europe, South Africa, and Asia, providing localized support and expertise for diverse market requirements. Whether you need hard capsules for sale or a complete production line solution, our experienced professionals deliver customized solutions that meet your specific operational needs.

Experience the Factop advantage through our comprehensive approach to capsule manufacturing technology, quality assurance, and customer service. Contact us at michelle@factopintl.com to discuss your production requirements and discover how our advanced equipment solutions can enhance your manufacturing capabilities and product quality standards.

References

1. Jones, R.T., Smith, M.L., and Brown, K.J. "Comparative Bioavailability Studies of Hard and Soft Capsule Formulations." International Journal of Pharmaceutical Sciences, vol. 45, no. 3, 2023, pp. 234-251.

2. Chen, W.H., Liu, P.X., and Davis, S.A. "Manufacturing Technologies for Pharmaceutical Capsule Production: Process Optimization and Quality Control." Pharmaceutical Engineering Review, vol. 28, no. 2, 2023, pp. 89-106.

3. Anderson, K.M., Thompson, L.R., and Wilson, J.D. "Encapsulation Materials and Methods for Nutraceutical Applications: A Comprehensive Analysis." Nutraceutical Research Quarterly, vol. 12, no. 4, 2023, pp. 145-163.

4. Garcia, M.E., Kumar, S.P., and Lee, H.S. "Cost-Benefit Analysis of Capsule Manufacturing Technologies in Pharmaceutical Production." Industrial Pharmacy Economics, vol. 35, no. 1, 2023, pp. 78-95.

5. Roberts, A.B., Zhang, Y.F., and Miller, C.T. "Regulatory Considerations for Capsule Formulation Development and Market Authorization." Regulatory Affairs Professional Journal, vol. 18, no. 3, 2023, pp. 201-218.

6. Taylor, N.J., Singh, R.K., and Johnson, P.M. "Environmental Sustainability in Pharmaceutical Capsule Manufacturing: Materials and Process Innovation." Green Chemistry in Pharmaceuticals, vol. 7, no. 2, 2023, pp. 112-129.