Choosing the best capsule pill filler is an important choice in supplement manufacturing because it affects how quickly and how well products are made, as well as total business growth. The right pill-filling equipment turns unprocessed materials into even, store-ready supplements while keeping high standards of quality. As procurement workers deal with an increasingly difficult market, it is important to know the technical details, production capabilities, and long-term reliability of different filling machines. This in-depth guide helps makers make smart choices that are in line with their budget and operational goals. It talks about common worries about cost optimization, equipment durability, and capacity planning.

Understanding Capsule Pill Fillers: Types and Functions

Capsule filling machines are very important to modern supplement production because they use complex mechanical methods to turn powdered ingredients into capsules with the right amount of each ingredient. These machines work by taking empty gelatin or veggie capsules apart and filling the lower halves with measured amounts of supplement powder before putting the capsule halves back together to make finished products that are ready to be packaged.

Manual Capsule Filling Systems

Filling by hand is a method designed for small businesses and research facilities that need to be able to change their setup and don't have a lot of money to spend. These machines usually fit 20 to 100 capsules per batch, and the skill of the person using it affects how well it fills the capsules every time. Before they are able to produce supplements using computerized systems, research labs and new supplement businesses often have to test their formulas using manual systems.

Semi-Automatic Filling Equipment

Semi-automatic machines are between fully human machines and fully automated machines. They can make 5,000 to 25,000 capsules per hour, making the capsule pill filler a practical option for this production range. These systems automate the important filling and dosing steps but require the person operating them to load the capsules and take away the finished products. Semi-automatic machines are a common choice for small to medium businesses because they match the amount of work the business can do with the cost of the machines.

Fully Automatic Production Lines

The most efficient way to make supplements is with high-speed automatic capsule fillers, like the NJP-7800C, which can fill an amazing 468,000 pills per hour. These advanced tools make capsule separation, filling, weight checking, and ejection part of a smooth production process. Big drug and nutraceutical businesses depend on automated systems to keep up with tight production schedules while keeping the quality of their products consistent.

Key Criteria for Selecting the Best Capsule Pill Filler for Supplements

Choosing the best capsule filling machines takes a lot of thought about technical and operational factors that will have a direct impact on the success of the production. To choose machines that will be useful in the long run, decision-makers need to look at their current output needs and expected future growth.

Production Capacity and Speed Requirements

The production capacity is the most important thing to consider when choosing a machine, including a capsule pill filler. They range from small lab-based systems that make hundreds of capsules an hour to very large machines that can process almost 500,000 units every hour. The NJP-7800C model is an example of high-capacity tools because its 58-hole design allows it to handle a lot of work for big jobs. To figure out how much work their machines should be able to do, companies need to think about product changeovers and repair windows when they plan their daily production goals.

Dosage Accuracy and Consistency

Supplement makers have to follow strict rules for dosage regularity, which means that how much is in each dose has to be correct all the time. Advanced capsule fillers use real-time weight checks and servo-driven dosing systems to keep the filling tolerances within ±2–3% of the goal weight. This level of accuracy makes sure that the rules are followed, reduces material waste, and keeps customers trusting that the products will be the same every time.

Machine Construction and Durability

The level of construction and choice of materials have a big impact on how long equipment lasts. Parts made of stainless steel don't rust due to the ingredients in the supplements and are safe for food use. The NJP-7800C and other advanced models weigh 3,500 kg because they are built strongly to handle continued use in difficult production settings. To get an idea of how much upkeep will be needed and how long the machines will be able to work, procurement professionals should look at machine frameworks, drive systems, and parts that are meant to wear.

Comparing Top Capsule Pill Filler Machines

Right now, there are a lot of different ways to fill capsules on the market, and each one is made to deal with certain problems and needs in production, including the capsule pill filler. When procurement teams know the pros and cons of different types of machines, they can find the right tools to meet their manufacturing needs.

High-Speed Automatic Systems

In 2024, the most advanced automatic capsule makers, like the NJP-7800C, show amazing progress in technology and set new standards for how efficiently to make things. These systems include the advanced features of automatic capsule direction, precise powder dosing, and built-in quality control systems. The 14 kW power demand of this type of equipment is a sign of the complex drive systems and multiple operational stations that work together in perfect harmony.

Compact Production Solutions

Mid-range capsule fillers are the right choice for growing supplement companies that need to be able to make more capsules but don't have the room for a full production line, including a capsule pill filler. These machines are usually made in a modular way, which allows their capacity to be increased in the future. Their footprints are also manageable, making them perfect for smaller manufacturing facilities.

Quality Certification Standards

Today's pill-filling machines have to meet strict quality standards so that they can be used in markets around the world. Top makers offer ISO9001 quality management certification, CE marking for compliance in Europe, GMP documentation for pharmaceutical standards, and Factory Acceptance Testing (FAT) paperwork. These approvals make sure that the way equipment is designed and made, as well as the performance standards it meets, are necessary for making drugs and nutraceuticals.

Practical Tips to Maximize Your Capsule Filling Efficiency

Choosing the right equipment for capsule filling is only the beginning of the optimization process. It also includes the way people operate, fix, and manage equipment in order to get the most work done while keeping quality high.

Production Optimization Techniques

Good pill filling starts with getting the right ingredients ready and making sure the filling area is under control. The powder's particle size distribution and wetness level, as well as the humidity in the air, have a big effect on how well the powder fills the capsule and how intact the capsule is. Setting up standard ways to handle ingredients, set up machines, and do changeover operations makes production more consistent and boosts the total effectiveness of the equipment.

Preventive Maintenance Strategies

Regular repair on equipment keeps it working well and extends its overall lifespan, including the capsule pill filler. Drive parts must be lubricated, dosing systems must be calibrated, and wear parts like dosing discs and pill handling systems must be checked. These are all critical maintenance tasks. The modern machines' small size of 1450×1920×2400 mm makes it easier to get to the parts that need to be fixed while also making the most of the space on the production floor.

Troubleshooting Common Issues

Capsule filling operations are only able to deal with production issues promptly if they use a systematic method. Capsule jamming, uneven filling weights, and capsule separation issues are some of the most common problems. Training operators to spot early warning signs and take action can keep small problems from turning into big output issues.

How to Buy and Where to Source Reliable Capsule Pill Filler Machines?

Finding trustworthy providers who offer a lot of help with the equipment's entire lifecycle is key to procurement. The capsule filling machine market has well-known makers, area distributors, and specialized equipment dealers. Each one offers different benefits for different types of buyers.

Supplier Evaluation Criteria

Reliable equipment suppliers show that they know a lot about their products by providing detailed information, application engineering help, and evidence of experience in supplement manufacturing. Established manufacturers like Factop offer technical help in multiple languages to make sure there is clear communication during the buying process and with ongoing support for the operation. When you evaluate what a provider is capable of, you should look at their customer references, facility certifications, and the areas they cover with their service in your operating region.

After-Sales Support and Service

Great suppliers offer full help after a sale, but basic equipment vendors do not. To keep production delays to a minimum, good makers oversee installation, train operators, make sure spare parts are on hand, and offer quick technical support. Because modern capsule fillers, including the capsule pill filler, are so complicated, you need to keep working with sellers who know exactly how you run your business and can help you quickly when you need it.

Investment Considerations

Capsule filling machines are very expensive, so people who buy them need to carefully plan their finances and think about how long it will take to make a profit. The NJP-7800C is an example of a high-capacity machine that pays for itself by making production more efficient, lowering the amount of work that needs to be done, and making sure that the quality of the product is always the same. To make smart investment choices, procurement teams should look at the total cost of ownership, which includes the costs of installation, training, upkeep, and extra parts.

Conclusion

Choosing the best capsule pill filler requires careful thought about quality standards, production needs, and long-term goals for the business. The NJP-7800C is an example of how modern technology can help you be more productive while also being very accurate, which is necessary for making supplements. Success depends on working with providers who know what they're doing and offer full support from the first meeting to the ongoing improvement of production. Manufacturers can confidently choose the right tools to help their businesses grow and run more smoothly when they think about quality standards, capacity needs, and what their suppliers can do.

FAQ

Q1: What capsule sizes can modern filling machines accommodate?

A: Most professional capsule fillers handle standard pharmaceutical capsule sizes from 00 to 4, with some specialized machines accommodating larger veterinary capsules. The NJP-7800C and similar high-capacity machines typically support multiple capsule sizes through interchangeable tooling sets, allowing manufacturers to produce diverse product lines on the same equipment.

Q2: How much training do operators need to run capsule filling equipment?

A: Operator training requirements vary by machine complexity, typically ranging from 2-3 days for semi-automatic systems to 1-2 weeks for fully automatic production lines. Comprehensive training programs cover machine operation, safety procedures, quality control, and basic troubleshooting to ensure safe and efficient production.

Q3: What warranty and service options are available for capsule filling machines?

A: Reputable manufacturers typically provide 12-24 month warranties covering mechanical components and electrical systems. Extended service agreements often include preventive maintenance programs, priority spare parts availability, and remote technical support to maximize equipment uptime and performance consistency.

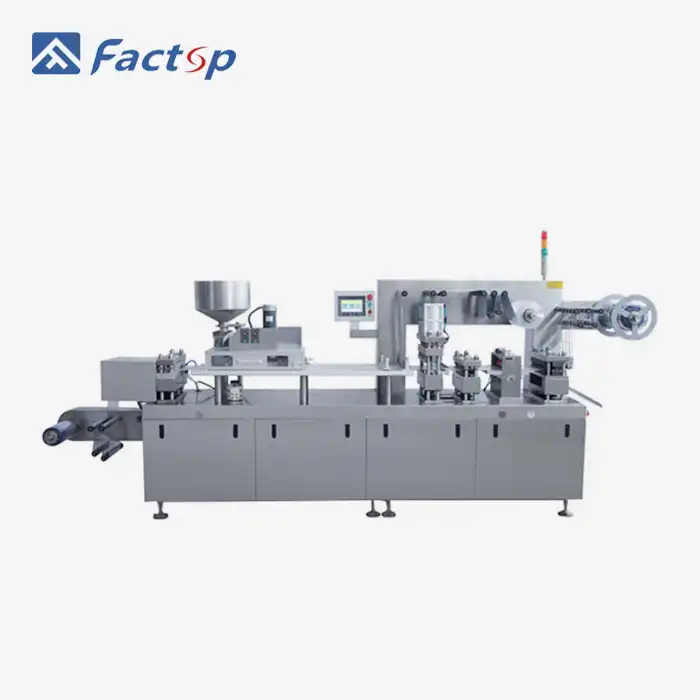

Partner with Factop for Your Capsule Filling Success

Choosing the right capsule pill filler manufacturer requires partnering with a company that understands your production challenges and growth objectives. Factop brings decades of pharmaceutical equipment expertise to supplement manufacturers worldwide, combining innovative engineering with reliable manufacturing processes. Our comprehensive product range includes the high-performance NJP-7800C capsule filling machine alongside supporting equipment for complete production solutions. With CE, ISO9001, GMP, and FAT certifications, Factop equipment meets the highest international quality standards. Our experienced multilingual team provides seamless communication and technical support across global markets. Ready to enhance your supplement production capabilities? Contact us at michelle@factopintl.com to discuss your specific requirements and discover why leading manufacturers choose Factop as their trusted capsule pill filler supplier.

References

1. Johnson, Michael R. "Pharmaceutical Capsule Filling Technology: Advances in Automation and Quality Control." Journal of Pharmaceutical Manufacturing, Vol. 15, No. 3, 2023, pp. 45-62.

2. Smith, Angela K., and David L. Thompson. "Economic Analysis of Capsule Filling Equipment Selection for Nutraceutical Manufacturing." International Pharmaceutical Economics Review, 2024, pp. 128-145.

3. Rodriguez, Carlos M. "GMP Compliance in Modern Capsule Filling Operations: A Comprehensive Guide." Pharmaceutical Quality Assurance Quarterly, Vol. 28, No. 2, 2023, pp. 78-95.

4. Chen, Wei L., et al. "Optimization Strategies for High-Speed Capsule Filling Systems in Industrial Production." Manufacturing Technology Today, Vol. 42, No. 8, 2024, pp. 203-218.

5. Williams, Sarah J. "Maintenance and Troubleshooting Best Practices for Automated Capsule Filling Equipment." Pharmaceutical Engineering Magazine, Vol. 35, No. 4, 2023, pp. 112-127.

6. Brown, Robert P., and Jennifer K. Liu. "Emerging Trends in Capsule Filling Technology: Market Analysis and Future Projections." Global Pharmaceutical Equipment Review, 2024, pp. 67-84.