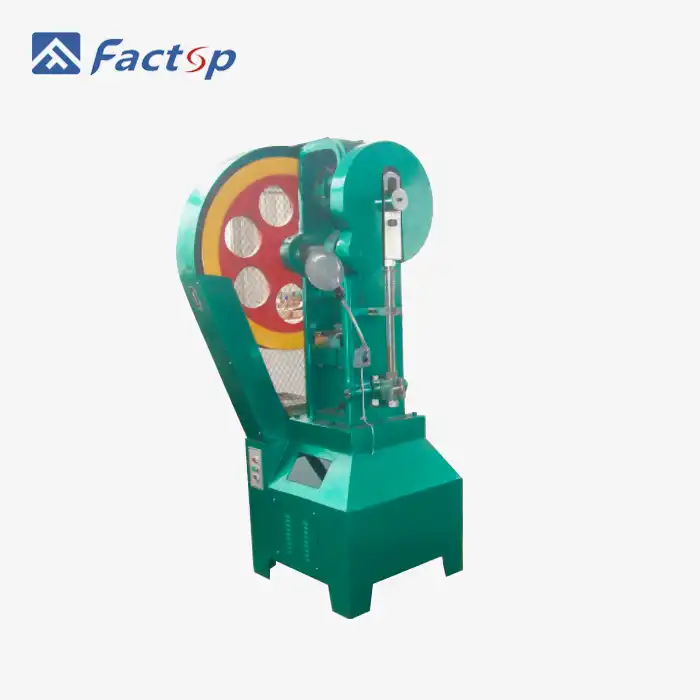

Large tablet press

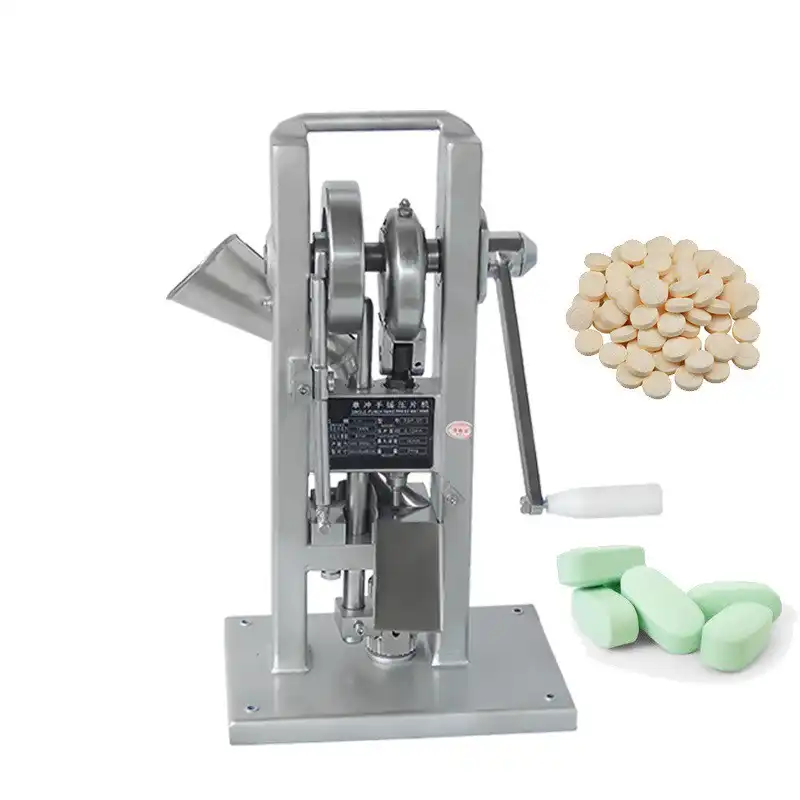

No. of punch die: 1 set

Pressure: 100KN

Max tablet diameter: 40mm

Max tablet thickness: 20mm

Production capacity: 3000pcs/hour

Large Tablet Press THP-10T: Professional Pharmaceutical Manufacturing Solution

Are you looking for a reliable Large tablet press to enhance your pharmaceutical production capabilities? The THP-10T model from Factop delivers exceptional performance for your tablet manufacturing needs. Whether you operate a pharmaceutical factory, health product facility, or hospital preparation room, this product offers the precision and reliability you need for consistent, high-quality tablet production.

Main Parameter

| Feature | Details |

|---|---|

| Model | Large Tablet Press |

| Capacity | 60,000 - 100,000 tablets/hour |

| Tablet Diameter | 3mm to 30mm |

| Press Force | 10 - 60 tons |

| Die Stations | Up to 35 stations |

| Motor Power | 5 - 15 kW |

| Control System | PLC with touch screen interface |

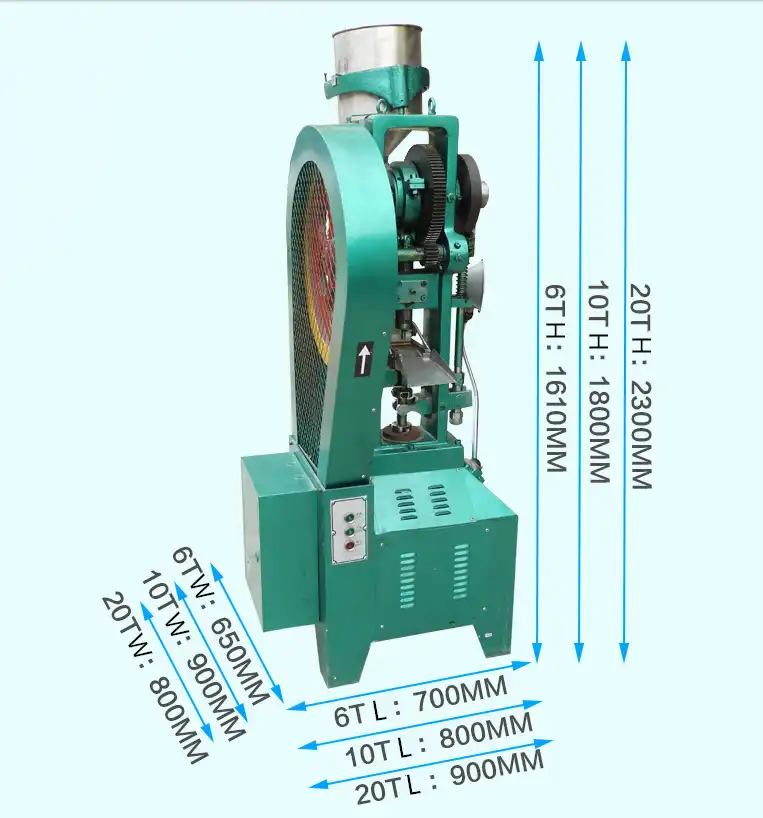

| Dimensions | Varies by model |

| Weight | 1000 - 5000 kg |

Why Choose Us?

Powerful Performance Specifications

The remarkable technological characteristics of the THP-10T model make it stand out. By applying 100KN of pressure, it guarantees that the density and quality of your tablets remain constant. Tablets up to 40 mm in diameter and 20 mm thick can be produced. It is ideal for medium- to large-scale companies because of its 3000 pieces per hour manufacturing capability.

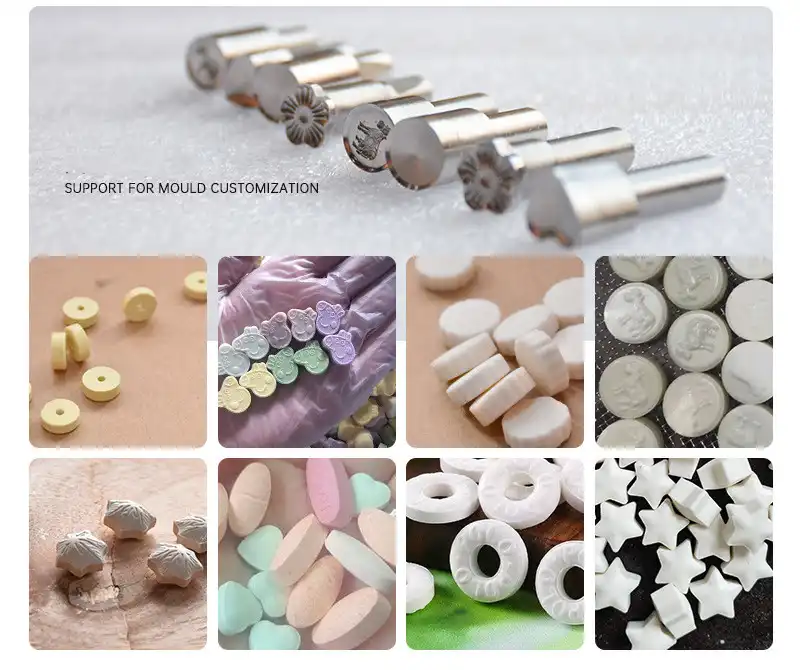

Versatile Applications

This industrial tablet production machine efficiently serves a variety of industries. It is used by pharmaceutical companies to make prescription drugs. It is used by producers of health products for dietary supplements. Its accuracy for bespoke formulas is useful in hospital preparation rooms. For their specific tablet manufacturing requirements, food industries and chemical plants also find it useful.

Large Tablet Press Application Areas

GMP-Certified Quality Standards

Your product satisfies stringent GMP certification standards. This guarantees adherence to global standards for pharmaceutical manufacture. Your trust in product quality and regulatory compliance is bolstered by the certification. The wooden box export packing that you receive safeguards your investment while it is being shipped.

Qualification Certification

Advanced Features for Professional Use

Precision Engineering

The single punch die system provides exceptional accuracy for each tablet. You get consistent weight, thickness, and hardness across your entire production run. The robust construction ensures long-lasting performance even under continuous operation.

User-Friendly Operation

Operating your tablet compression machinery becomes straightforward with intuitive controls. The design focuses on ease of use while maintaining professional-grade capabilities. Regular maintenance requirements stay minimal, reducing downtime and operational costs.

Comprehensive Support Services

Factop provides complete installation and commissioning support at your facility. Our experienced technical team ensures proper setup and optimal performance. You receive free spare parts for one year after purchase, protecting your investment and ensuring uninterrupted production.

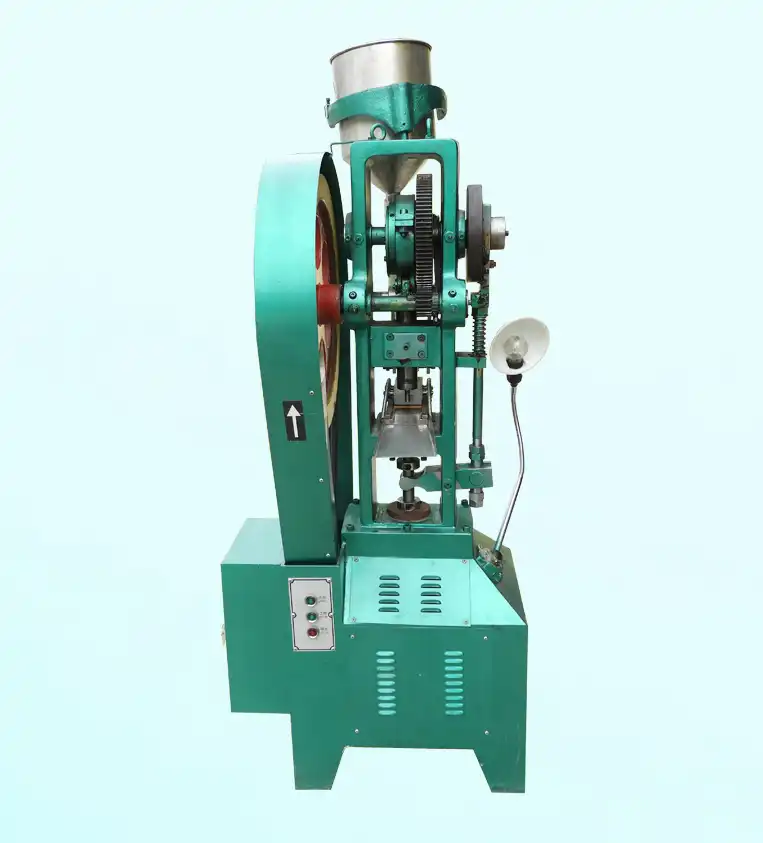

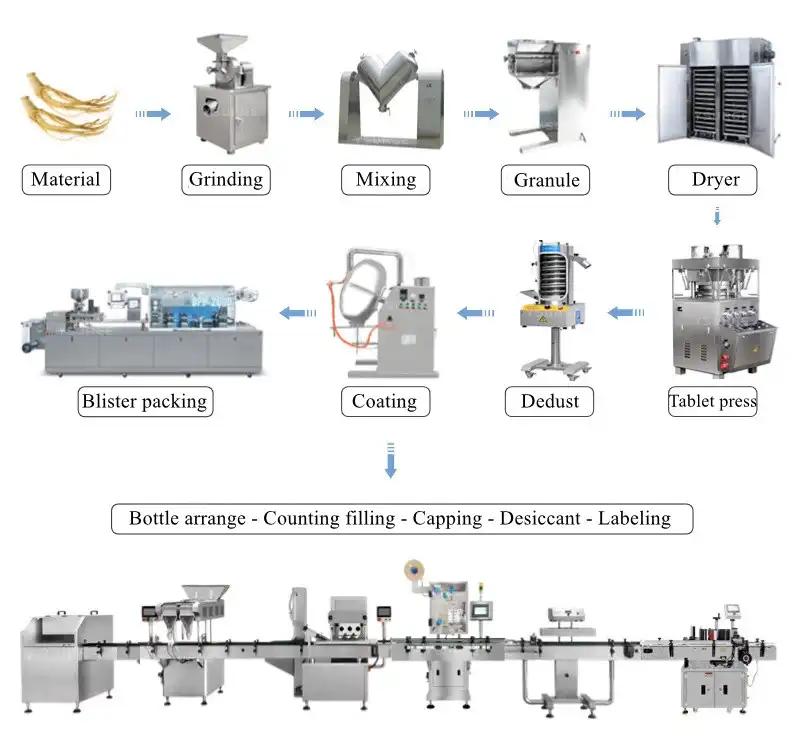

Production Process

Technical Excellence and Reliability

Proven Manufacturing Heritage

Factop brings extensive experience in pharmaceutical machinery manufacturing. Our professional team understands international trade requirements and quality standards. We maintain long-term partnerships with customers across America, Europe, South Africa, Korea, Philippines, and Indonesia.

Quality Assurance Process

Every Large tablet press undergoes rigorous FAT testing before delivery. This factory acceptance testing confirms all specifications meet your requirements. The certification documentation supports your regulatory compliance efforts.

Fast Delivery Commitment

We understand your production schedules are critical. Our streamlined manufacturing and logistics processes ensure prompt delivery. The efficient supply chain minimizes waiting time so you can start production quickly.

Flower basket tablet machine real photos show:

Investment in Your Success

Cost-Effective Solution

Your investment in this tablet production equipment is well worth it. Long-term cost savings are produced when performance, dependability, and thorough support are combined. Your return on investment is maximized by constant productivity and fewer maintenance needs.

Partnership Approach

The principles of honesty, creativity, collaboration, and win-win partnerships guide Factop's operations. Every client is seen as a long-term collaborator in our success. Throughout the whole buying and ownership process, our bilingual staff makes communication easy.

Global Service Network

Our international experience enables effective support regardless of your location. The team's familiarity with diverse market requirements ensures appropriate solutions for your specific needs.

After-sales Service

Contact Us

Ready to enhance your tablet production capabilities? Contact our expert team to discuss your specific requirements. We provide detailed technical consultations to ensure the THP-10T model perfectly matches your production goals.

For more information about our Large tablet press solutions and to request a detailed quotation, reach out to michelle@factopintl.com. Let us help you achieve your pharmaceutical manufacturing objectives with reliable, high-quality equipment.