Candy panning machine

Material: Stainless steel

Stock: In stock

Applicable: Pharmaceutical, chemical, food

Suitable: Tablets, pills, granules

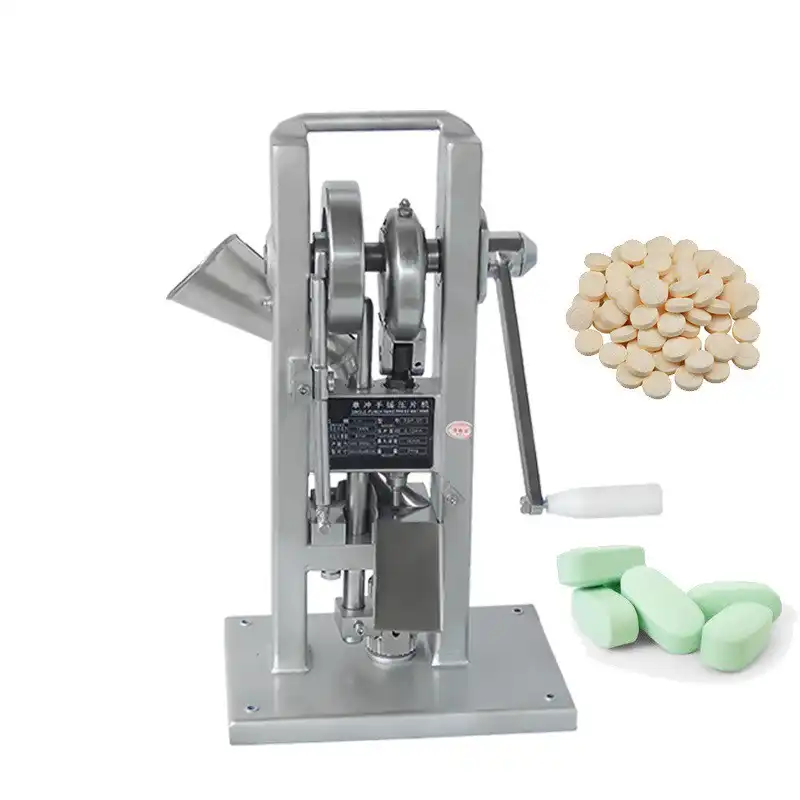

Professional Candy Panning Machine for High-Quality Coating Production

Looking for a reliable Candy panning machine to enhance your production efficiency? Our BYC1250 model does a great job of coating tablets, pills, and granules in the chemical, food, and medicinal businesses. Precision engineering and easy operation go hand-in-hand in this high-tech painting equipment. This way, you'll always get a professional-grade finish. Because it is made of high-quality stainless steel, this machine will last a long time and meet strict GMP standards for safe work settings.

Specifications

| Feature | Details | ||

|---|---|---|---|

| Model | BYC800 | BYC1000 | BYC1250 |

| Production capacity | 30-50kg/time | 50-70kg/time | 80-150kg/time |

| Pot diameter | 800mm | 1000mm | 1250mm |

| Motor power | 1.5kw | 1.5kw | 2.2kw |

| Inlet heating power | 2kw | 2kw | 4kw |

| Outlet heating power | 2kw | 2kw | 2kw |

| Rotary speed | 32rpm | 32rpm | 28rpm |

| Machine Weight | 230kg | 260kg | 370kg |

| Dimension | 1100*800*1320mm | 1200*1000*1420mm | 1380*1250*1650mm |

Candy Panning Machine details information

Advanced Features for Superior Coating Results

Our coating equipment incorporates cutting-edge technology to streamline your production process. The BYC1250 model features precise temperature control systems that maintain optimal coating conditions throughout operation. You can easily adjust rotation speed to match different product requirements.

The stainless steel drum design makes sure that the covering is spread out evenly and keeps the product from getting dirty. Many spray guns make sure that all areas are evenly covered. Monitoring tools for temperatures help you keep quality standards uniform.

Safety features include emergency stop buttons and guards that go around moving parts to keep them safe. For better process monitoring, the control panel shows working data in real time. Maintenance time between production runs is cut down by surfaces that are easy to clean.

Versatile Applications Across Multiple Industries

This coating machine serves diverse manufacturing needs across various sectors. Pharmaceutical companies use it for tablet coating to improve taste, appearance, and shelf life. Food manufacturers rely on it for candy coating, chocolate enrobing, and confectionery production.

Chemical industries benefit from protective coating applications that enhance product stability. Health supplement manufacturers achieve professional-grade capsule and tablet finishing. The machine handles different batch sizes efficiently, making it suitable for both small-scale operations and large production facilities.

You can process various materials including sugar coatings, film coatings, and protective barriers. The versatile design accommodates different product shapes and sizes without requiring extensive setup changes.

Application Areas

Technical Specifications and Quality Standards

Strong materials are used to make the BYC1250 device work reliably. Components made of stainless steel don't rust and meet the cleanliness standards needed in food and drug uses. For the best covering bonding, the machine only works within certain temperature ranges.

GMP certification ensures compliance with international quality standards. Professional engineering guarantees long-term reliability and consistent output quality. The compact design fits efficiently into existing production lines without requiring extensive facility modifications.

Export packing made of wooden boxes keeps your items safe while they're being shipped. FAT testing and approval make sure the quality of the product before it is delivered. On-site installation and testing help makes sure that everything is set up correctly and works at its best from the start.

Comprehensive Support and Service Excellence

Factop provides complete technical support throughout your equipment lifecycle. Our experienced team offers multilingual customer service to address your specific requirements. Free spare parts coverage for one year after purchase minimizes operational costs.

Professional installation services ensure proper setup and training for your operators. We provide ongoing technical consultation to optimize your coating processes. Our global service network delivers prompt support across America, Europe, South Africa, Korea, Philippines, Indonesia, and other regions.

Maintenance training helps your team keep the Candy panning machine running at peak efficiency. Regular service intervals extend equipment life and maintain production quality standards.

Investment Benefits and Return Value

This coating equipment delivers significant operational advantages for your business. Consistent coating quality reduces waste and improves product appearance. Automated operation minimizes labor costs while increasing production capacity.

Energy-efficient design keeps operating costs manageable over time. Durable construction ensures years of reliable service with minimal maintenance requirements. The machine's versatility allows you to serve multiple product lines with a single investment.

Quick changeover capabilities reduce downtime between different coating applications. Precise control systems help you achieve repeatable results that meet customer specifications consistently.

Real Photos & Packing

Contact Us

Ready to Transform Your Production?

Start enhancing your coating operations with our professional Candy panning machine today. Contact our expert team at michelle@factopintl.com for detailed specifications and competitive pricing. We're ready to help you achieve superior coating results.

YOU MAY LIKE