Softgel encapsulation

Max capacity: 86400pcs/hour

Die roller dimension: 103*200mm

Die roller speed: 0-6rpm

Power: AC380V 50HZ 7KW

Certificate: CE, GMP, FDA, ISO9001, FAT

Weight: 1250kg

Dimension: 1680*770*1800mm

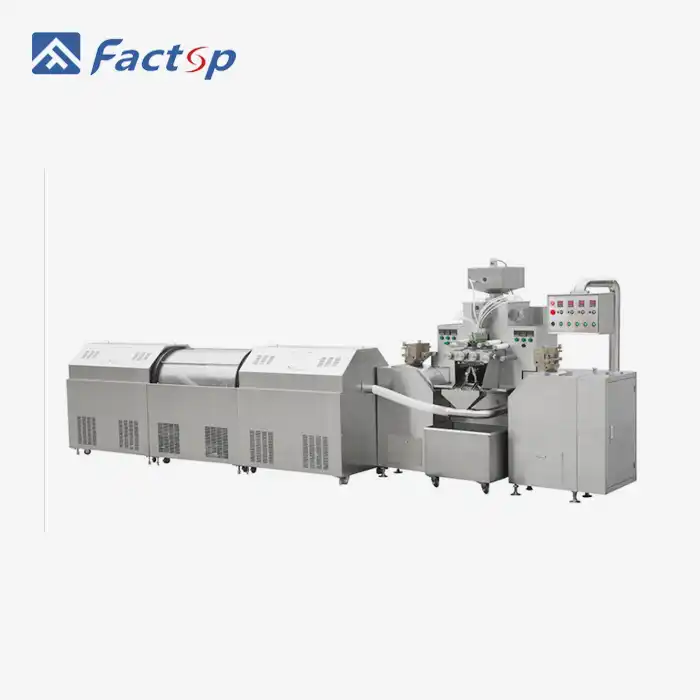

Softgel Encapsulation Machine HSR-200: Professional Manufacturing Solution

Are you looking for reliable Softgel encapsulation equipment that delivers consistent results? The HSR-200 from Factop International Trade Company offers superior performance for pharmaceutical manufacturers worldwide. Our cutting-edge technology makes sure that exact capsules are made to the highest quality standards. This machine gives you the dependability you need for business production, whether you're making vitamins, drugs, or nutraceuticals. We've been making things for years, so we know the problems you're having with production and have come up with answers that work.

Specifications

| Feature | Details |

|---|---|

| Output Capacity | Max 86400 capsules/hour |

| Roll mold size | 103*200mm |

| Roll mold speed | 0-10rpm |

| Roll mold pressure | 0.1-0.5MPa |

| Supply material | 12*(0-2)ml |

| Filling accuracy | 1% - 2% |

| Motor power | 380V, 6KW |

| Weight | 1150 kg |

| Dimension | 1700*750*1900mm |

Why Choose Our Softgel Encapsulation Technology?

Exceptional Production Capacity

86,400 pieces per hour is the highest capacity that the HSR-200 can produce, which is great. Meeting strict deadlines without sacrificing quality is made possible by this high-speed manufacturing capabilities. The smooth operation of your production lines will enable you to promptly fulfill massive orders.

Precision Engineering Features

Our die roller system has changeable speeds between 0 and 6 rpm and measures 103 by 200 mm. You may modify manufacturing settings for various capsule sizes and formulas thanks to this flexibility. Consistent capsule thickness and flawless encapsulation are guaranteed by the exact control.

Robust Construction and Reliability

With a weight of 1250 kg and dimensions of 16807701800 mm, the HSR-200 was designed to be durable. Stable functioning is guaranteed even during lengthy production cycles because to the sturdy structure. With our one-year free spare parts warranty, your investment is safeguarded.

Technical Specifications That Matter

With a 7KW power usage and AC380V 50HZ operation, the machine is energy-efficient for continuous use. These requirements maintain controllable operating costs while guaranteeing dependable performance.

Our equipment meets international quality standards including CE, GMP, FDA, ISO9001, and FAT certifications. These certifications demonstrate our commitment to quality and safety in pharmaceutical manufacturing.

Comprehensive Support Services

Installation and Training

We provide on-site installation and commissioning support to ensure your Softgel encapsulation system operates perfectly from day one. Our technical team will train your operators and ensure smooth integration with your existing production line.

Quality Assurance

Every machine undergoes rigorous FAT testing before shipment. This comprehensive testing ensures your equipment meets all specifications and performance standards. You receive detailed certification documentation with your purchase.

Professional Packaging

Your investment is protected during shipping with our wooden box export packaging. This secure packaging meets international shipping standards and ensures your equipment arrives in perfect condition.

Softgel Encapsulation Production Line:

Applications Across Industries

Our product machines serve diverse sectors including:

- Pharmaceutical manufacturing facilities

- Health product production companies

- Hospital preparation departments

- Food supplement manufacturers

- Chemical processing plants

- Nutraceutical producers

The versatility of our equipment makes it suitable for various formulations and production requirements. Whether you're producing vitamins, herbal extracts, or pharmaceutical compounds, the HSR-200 adapts to your needs.

Why Factop Stands Apart?

With extensive experience in pharmaceutical machinery manufacturing, we understand the unique challenges you face. Our team combines technical expertise with deep industry knowledge to deliver solutions that work.

We maintain GMP-certified manufacturing facilities ensuring every machine meets the highest quality standards. Fast delivery times mean you won't experience lengthy production delays waiting for equipment.

Our bilingual technical staff can assist with your projects from anywhere in the world and is aware of the demands of international trade. In America, Europe, South Africa, Korea, the Philippines, and Indonesia, we have formed fruitful partnerships.

Machine Real Photos Show:

Operating Excellence

Your operators will spend less time training thanks to the HSR-200's intuitive design. Operation is simple and precise thanks to intuitive controls and clear displays. Simple routine maintenance keeps your production operating smoothly and minimizes downtime.

Energy-efficient operation helps control operational costs while delivering consistent performance. The reliable product process ensures minimal waste and maximum yield from your raw materials.

Contact Us

Ready to enhance your production capabilities? Contact our team to discuss your specific requirements. We'll help you determine the best configuration for your needs and provide detailed technical specifications.

Our experienced professionals can answer your questions about installation requirements, production capabilities, and ongoing support services. Every inquiry receives prompt, professional attention from our knowledgeable staff.

Transform your production capabilities with proven Softgel encapsulation technology. Contact michelle@factopintl.com today to learn how the HSR-200 can optimize your manufacturing operations and drive business growth.

YOU MAY LIKE