blister sealer machine

Suitable: Pharmaceutical, food, lab

Packing material: PVC, Aluminum, PP

Stock: In stock

Certificate: CE, ISO9001, GMP

Finished product: Alu-Alu, Alu-pvc

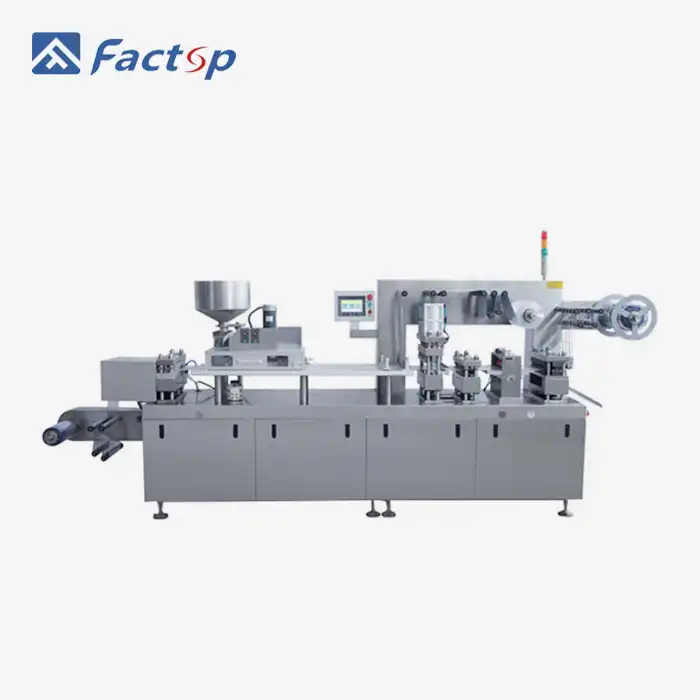

Professional Blister Sealer Machine for Pharmaceutical Packaging Excellence

Are you looking for a reliable packaging solution that delivers consistent results every time? Our DPP140 blister sealer machine represents the perfect blend of precision engineering and user-friendly operation. This high-tech pharmaceutical packing tools makes your production line more efficient while still meeting the highest quality standards. This machine is very flexible and can easily and reliably be changed to fit your unique packing needs, whether you run a lab, a pharmaceutical factory, or a food processing facility.

Specifications of blister sealer machine

| Punching frequency: 10-40 times/min, 4800plate/hour | |

| Normal section: 57*80mm | Specification: 27*110mm one plate per time |

| Max forming area: 130*110*26mm | 60*100mm one plate per time |

| The feed stroke range: 20-70mm | |

| Yield rate: more than 99% | Motor power: 1.5kw |

| Forming heating power: 0.9kw | Low heating power: 0.9kw |

| Heat sealing power: 0.8kw | Gas mercury passenger volume: more than 0.3m3 |

| Cooling: circulating water or tap water | Weight: 600kg |

| Dimension: 2150*550*1370mm | |

| Packing material: Medicinal PVC 0.3*140MM Aluminum foil 0.023*140mm | |

Key Features and Specifications

It is easy to see that the DPP140 model stands out in the market for packing machines. Its sturdy design makes it easy to work with a variety of materials, such as PVC, metal, and PP. You'll like that the machine can make finished goods out of both Alu-Alu and Alu-PVC.

This equipment suits various industries perfectly. Pharmaceutical companies rely on its accuracy for medication packaging. Food manufacturers trust its hygienic design. Laboratory facilities value its precise control systems.

The compact design doesn't compromise on performance. You get professional-grade results without requiring excessive floor space. The intuitive control panel makes operation straightforward for your team members.

Advanced Technology for Superior Performance

Our engineering team used cutting-edge technology to make this blister packing tools. The temperature control device makes sure that the closing conditions are perfect. The pressure levels will change automatically based on the properties of the material you are using.

You'll notice the smooth operation immediately. The machine runs quietly while maintaining consistent output rates. Quality sensors monitor each seal to prevent defective packages from reaching your customers.

The heating parts make sure that the closing area is always at the same temperature. This even spread of heat gets rid of any weak spots in your packing. The best safety is given to your goods while they are being stored and shipped.

Versatile Applications Across Industries

Pharmaceutical factories benefit from the machine's GMP compliance features. The stainless steel construction meets strict hygiene requirements. Easy cleaning procedures minimize downtime between production runs.

Food processing facilities appreciate the equipment's versatility. It handles various product sizes and shapes efficiently. The adjustable settings accommodate different packaging requirements seamlessly.

The small size is perfect for smaller production rates in hospital preparation rooms. The exact control features are highly valued in lab settings for study purposes.

Health product manufacturers rely on the consistent sealing quality. Chemical plants trust the durable construction for demanding applications. Food supplement companies appreciate the flexible material compatibility.

Application Areas

Quality Assurance and Compliance

Every machine is up to the highest quality standards around the world. CE approval shows that you follow European rules. Our quality control methods are confirmed by our ISO9001 certification. GMP approval makes sure that the pharmaceutical business can work together.

The wooden box export packaging protects your investment during shipping. FAT testing provides comprehensive performance verification before delivery. These quality measures give you confidence in your purchase decision.

Before shipments go out, our expert team does thorough checks. Each part goes through strict testing procedures. You get tools that can be used right away for production.

Comprehensive Support Services

With on-site installation help, everything is set up correctly from the start. Our skilled experts will walk you through the process of starting. Your workers will learn how to use the tools faster if they get training on it.

For one whole year, free extra parts support will keep your investment safe. We're sure that the machine will work well, as shown by this thorough guarantee. When you buy packing tools, you can rest easy.

Fast delivery options minimize your waiting time. Our logistics team coordinates shipment details efficiently. You receive your blister sealer machine according to your production schedule requirements.

After placement, technical help lasts for a long time. Our multicultural team knows what it takes to do business internationally. Making sure people can respond quickly keeps your production line running smoothly.

Packaging and Transportation

Contact Us

Ready to enhance your packaging capabilities? Contact our experienced team at michelle@factopintl.com for detailed specifications and pricing information. We'll help you find the perfect blister sealer machine solution for your specific requirements.

YOU MAY LIKE