Pill compressor machine

Name: Middle double-press automatic tablet machine

Max pressure: 60KN

Max tablet diameter: 30mm

Production capacity: 18000pcs/hour

Material: Stainless steel

Pill Compressor Machine - Professional Tablet Manufacturing Solution

Are you looking for a reliable pill compressor machine to boost your pharmaceutical production? You've found the perfect solution. Modern pharmaceutical centers can use our ZP226 line, which is the most advanced technology for making tablets. This product meets the best quality standards and performs exceptionally well. Our tools makes sure that you always get skilled results, whether you're in charge of a drug factory, a health product facility, or a hospital preparation room.

With maximum pressure capability of 60KN and production speeds reaching 18,000 pieces per hour, this machine transforms raw materials into perfectly formed tablets with remarkable efficiency.

Specifications

| Specification | Details |

|---|---|

| Model | ZP226-10 Pill compressor machine |

| Output Capacity | 15000pcs/hour |

| Tablet Size | Max 25mm |

| Compression Force | 80KN |

| Tablet Thickness | 6mm |

| Power Supply | 3kw |

| Dimensions | 650*650*1600mm |

| Punch die No. | 10 sets |

| Weight | 1000kg |

Key Features That Set Our Equipment Apart

Superior Performance Specifications

Our ZP226 line has units with eight, ten, and twelve stations. So you can use different sizes of products, each type can handle tablets that are up to 30 mm across. Using stainless steel for the construction makes it last a long time and meet high standards for cleanliness.

The automatic process cuts down on worker costs while keeping quality high. The easy-to-use design and consistent performance will be appreciated by your production team every day.

GMP-Certified Manufacturing Standards

When it comes to pharmacy tools, quality matters. That's why our building has GMP approval, which makes sure that all of our products meet foreign standards. With this approval, you can be sure that the rules will be followed and the goods will be safe.

We conduct thorough FAT (Factory Acceptance Testing) before shipment. This testing process verifies that your equipment performs to specifications before it leaves our facility.

Complete Support Package

Installation and Training Services

When you invest in our tablet pressing equipment, you receive comprehensive support. Our technical team provides on-site installation and commissioning services. This hands-on approach ensures your equipment operates optimally from day one.

We also offer training for your operators. Proper training maximizes equipment efficiency and extends machine lifespan.

Warranty and Spare Parts

Your investment is protected with our one-year warranty program. Free spare parts are included during the first year, minimizing unexpected costs. Our experienced technical team provides ongoing support whenever you need assistance.

Fast delivery ensures minimal downtime for your production schedule. We understand that time is money in pharmaceutical manufacturing.

Versatile Applications Across Industries

This versatile equipment serves multiple industries beyond traditional pharmaceuticals. Food factories use our machines for nutritional supplements and vitamin tablets. Chemical plants rely on our equipment for specialized compressed products.

Health product makers like how reliable the quality and effectiveness are. The small size and steady operation are good for hospital preparation rooms.

The pill compressor machine adapts to various formulations and tablet designs, making it an excellent choice for diverse production needs.

Application Areas

Technical Excellence and Innovation

Advanced Control Systems

In today's world, business needs accurate control. Our tools have high-tech control systems that keep an eye on speed, pressure, and the quality of the tablet all the time. These steps help keep things from going wrong and guarantee the same outcome every time.

Operators can easily adjust settings for different products. Quick changeover capabilities reduce downtime between production runs.

Robust Construction

Stainless steel construction provides excellent corrosion resistance and easy cleaning. This material choice supports Good Manufacturing Practices and extends equipment life.

The sturdy frame design minimizes vibration and ensures stable operation even at maximum production speeds.

Global Partnership and Support

Factop has built strong relationships with customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our multilingual team understands international trade requirements and cultural nuances.

We believe in long-term partnerships rather than simple transactions. This approach has earned us loyal customers who trust our equipment and service.

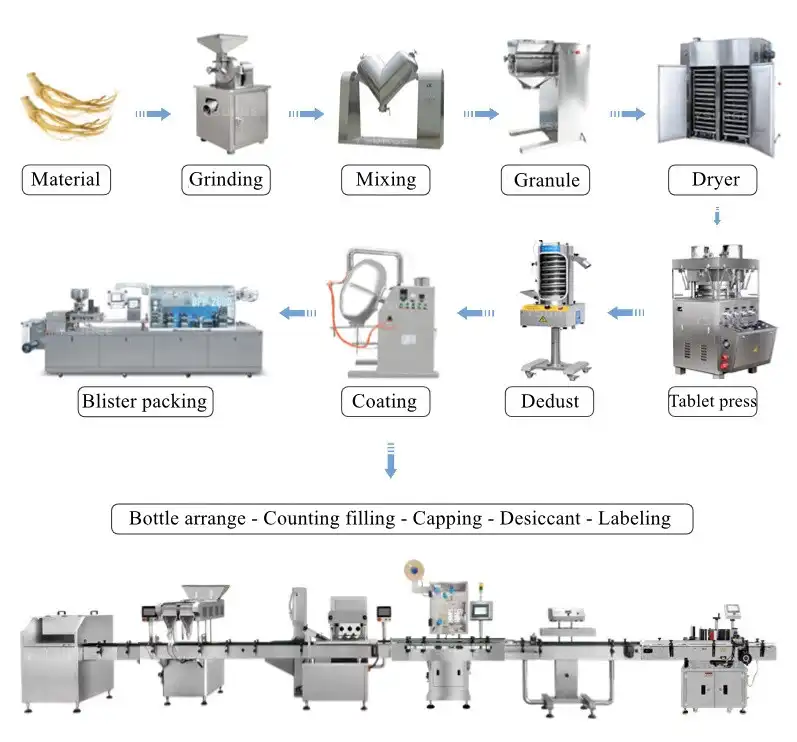

Production Process

Why Choose Us?

Proven Track Record

We've been making medication tools for years, so we know a lot about the business. We understand the issues you're facing and create solutions that work in the business world.

Our proven technical team brings expertise to every project. They work closely with customers to ensure optimal equipment selection and configuration.

Comprehensive Product Range

In addition to tablet presses, we also make pill filling machines, mixing tools, granulators, and ways to package things. With this wide range, we can support your whole production line with high-quality tools that works well together.

Quality Assurance

Every product undergoes rigorous quality testing before shipment. Our quality assurance program ensures consistent performance and reliability.

Wooden boxes are a safe way to keep your things safe when you ship them abroad. Your gear will get to you in great shape because we take care of everything.

Our Wearhouse Show

Contact Us

Ready to Enhance Your Production Capabilities?

Transform your tablet manufacturing with our advanced pill compressor machine technology. Contact michelle@factopintl.com today to discuss your specific requirements and discover how our equipment can improve your production efficiency and product quality.

YOU MAY LIKE