Capsule blister packing machine

Suitable: Pharmaceutical, food, lab

Material: Stainless steel

Certificate: CE, ISO9001, GMP

Finished product: Alu-Alu, Alu-pvc

Capsule Blister Packing Machine - Professional Pharmaceutical Packaging Solution

Looking for a reliable pharmaceutical packaging solution? Our Capsule blister packing machine delivers exceptional performance for your production needs. The DPP260 model combines advanced technology with user-friendly operation. You can trust this equipment to handle various capsule sizes efficiently. Whether you run a pharmaceutical factory, health product facility, or laboratory, this machine meets your packaging requirements. Built with premium stainless steel construction, it ensures durability and compliance with industry standards. Your production line will benefit from consistent, high-quality blister packaging output.

Specifications

| Punching frequency: 20-35 times/min, 80-120plate/min | |

| Max forming area: 8260*150*18mm | |

| The feed stroke range: 30-120mm | |

| Yield rate: more than 99% | Motor power: 8.5kw |

| Cooling: circulating water or tap water | Weight: 1850kg |

| Dimension: 4460*760*1620mm | |

| Packing material: Medicinal PVC 0.25-0.5*260MM Aluminum foil 0.02-0.035*260mm | |

Why Choose Our Blister Packaging Equipment?

Using efficient packing is important. To make this machine, we used precise engineering. Flexible packing choices are available, such as Alu-Alu and Alu-PVC combinations. When using different types of capsules, the equipment works perfectly.

Our production skills come from years of developing pharmaceutical machines. The gear you get meets GMP standards right away. The stainless steel structure makes it easy to clean and fix. The easy-to-use control system will be appreciated by your workers.

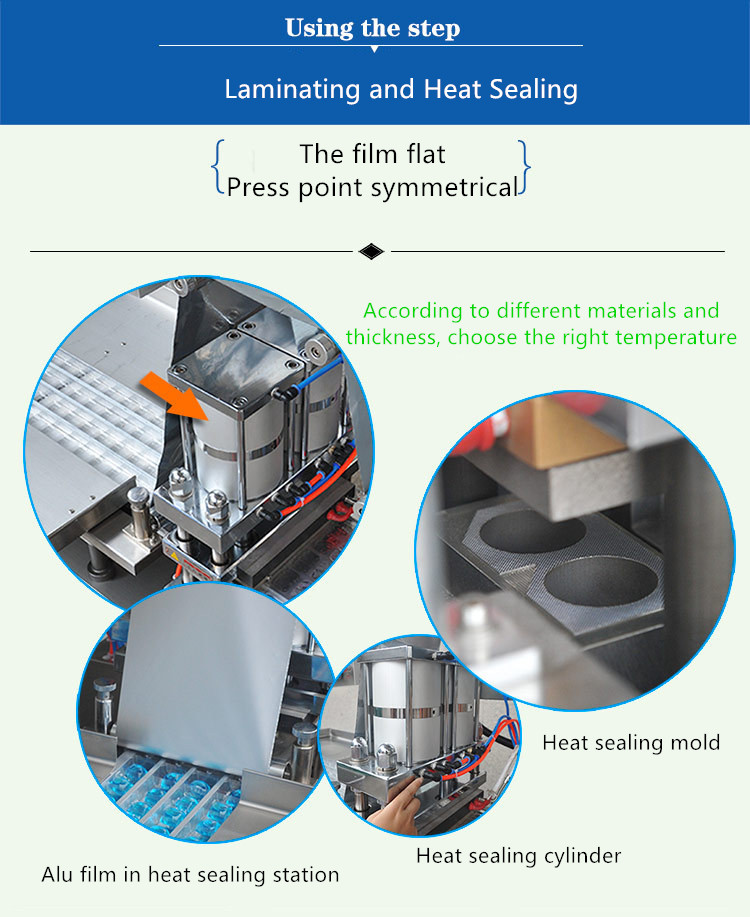

Quality control is built into every component. You can expect consistent sealing strength and perfect blister formation. The machine processes capsules at optimal speeds without compromising quality. Your product integrity remains protected throughout the packaging process.

Technical Specifications and Features

The DPP260 type has great features for medium- to large-scale activities. You can easily package different-sized capsules. The machine has settings that let you change the forming depth and closing temperature.

Key technical advantages include:

- Robust stainless steel frame construction

- Precise temperature control systems

- Adjustable packaging speed settings

- Multiple safety protection mechanisms

- Easy-to-replace tooling components

Your maintenance team will find servicing straightforward. All major components are easily accessible. We provide comprehensive technical documentation with your purchase. Regular maintenance keeps your equipment running at peak performance.

Applications Across Industries

This Capsule blister packing machine serves multiple industry sectors effectively. Pharmaceutical companies rely on our equipment for prescription medications. Health product manufacturers use it for supplements and vitamins. Food industry clients package nutritional capsules safely.

Laboratory settings benefit from smaller batch capabilities. Hospital preparation rooms find the equipment perfect for specialized formulations. Chemical plants use it for encapsulated products requiring protective packaging.

Your specific application requirements are important to us. We can discuss customization options during consultation. The machine adapts to various production volumes and packaging specifications.

Application Areas

Quality Assurance and Certifications

You deserve equipment that meets international standards. Our machines carry CE certification for European compliance. ISO9001 quality management ensures consistent manufacturing processes. GMP certification guarantees pharmaceutical industry suitability.

Factory Acceptance Testing (FAT) comes standard with every purchase. You receive detailed test reports before shipment. Our quality team inspects each machine thoroughly. Wooden box export packaging protects your investment during shipping.

We stand behind our manufacturing quality. Free spare parts coverage extends one year from purchase date. Your peace of mind matters to us.

Installation and Support Services

Professional installation support is available for your facility. Our technical team provides on-site commissioning services. You receive comprehensive operator training during installation. We ensure your team understands all operating procedures.

Technical support continues after installation. Our multilingual support team assists with any questions. Remote troubleshooting helps resolve issues quickly. Regular maintenance schedules keep your product performing optimally.

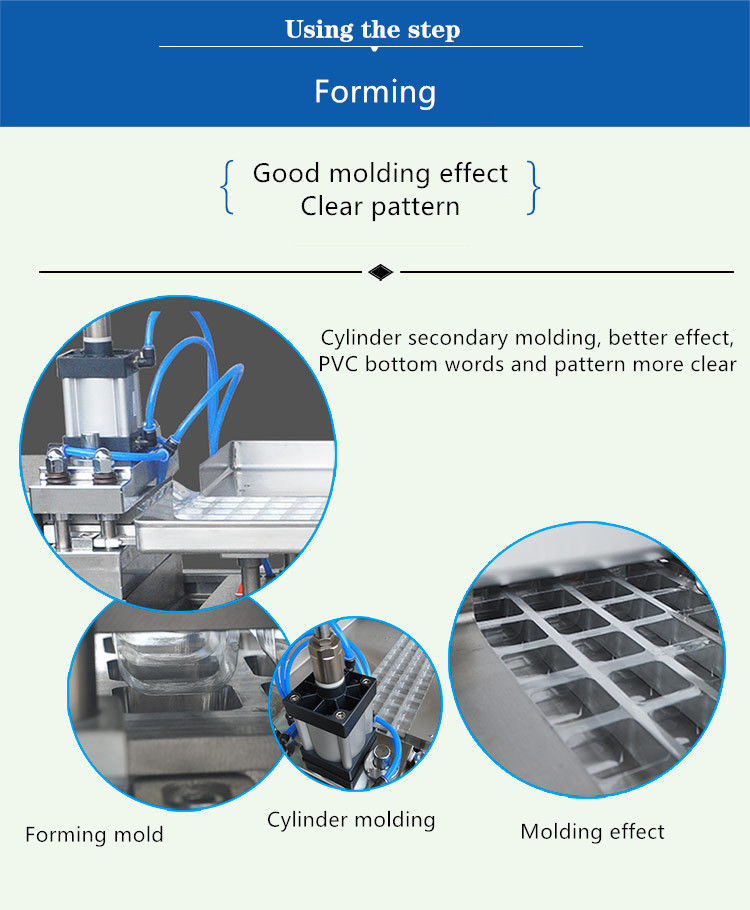

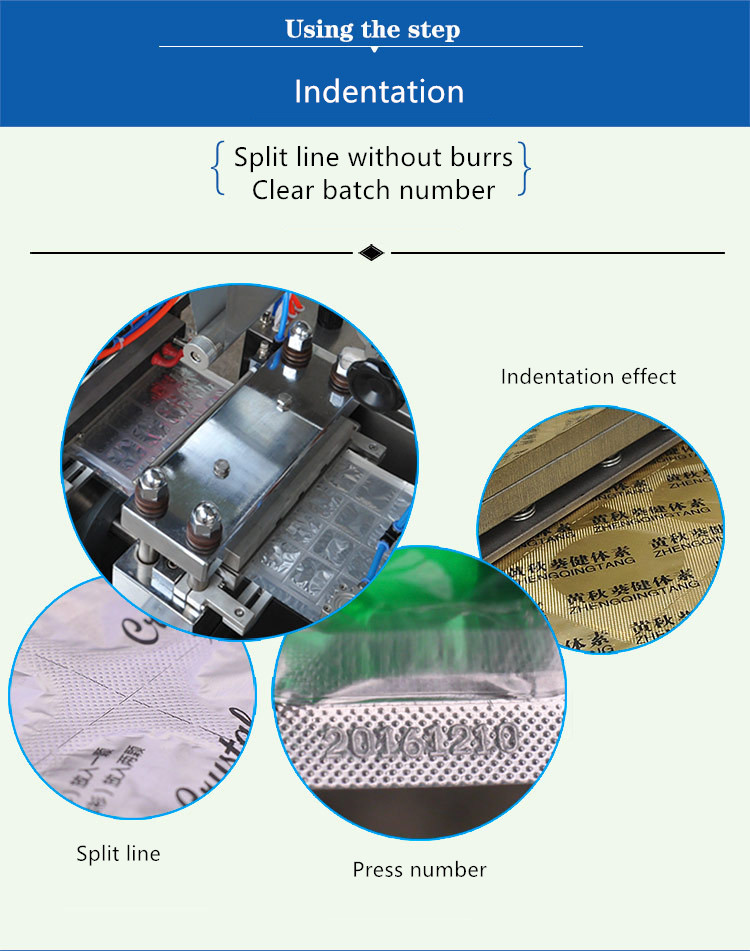

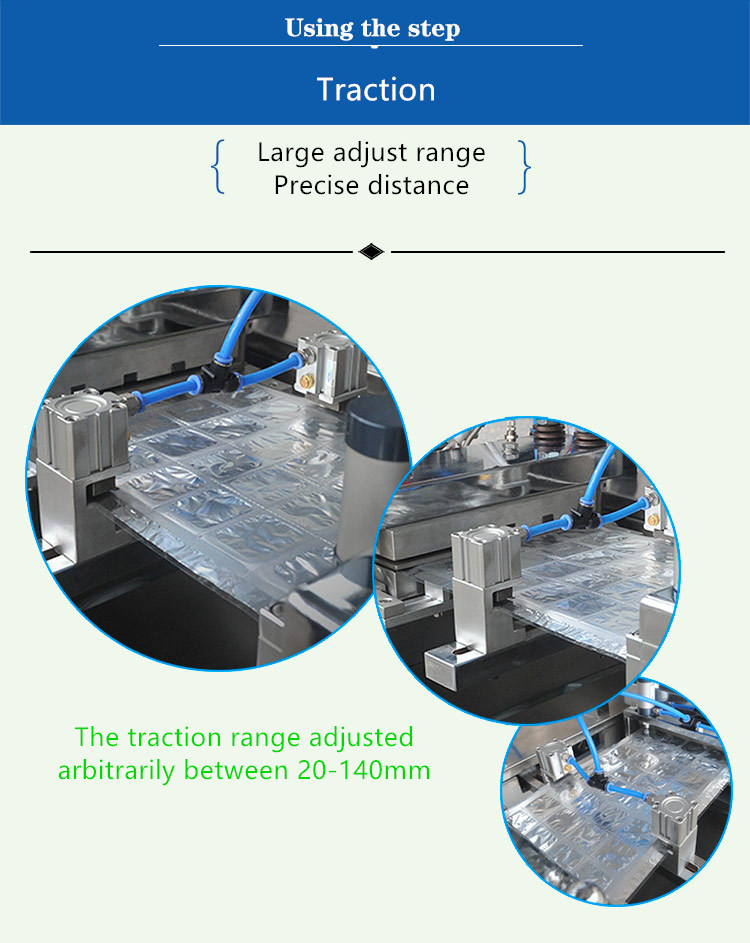

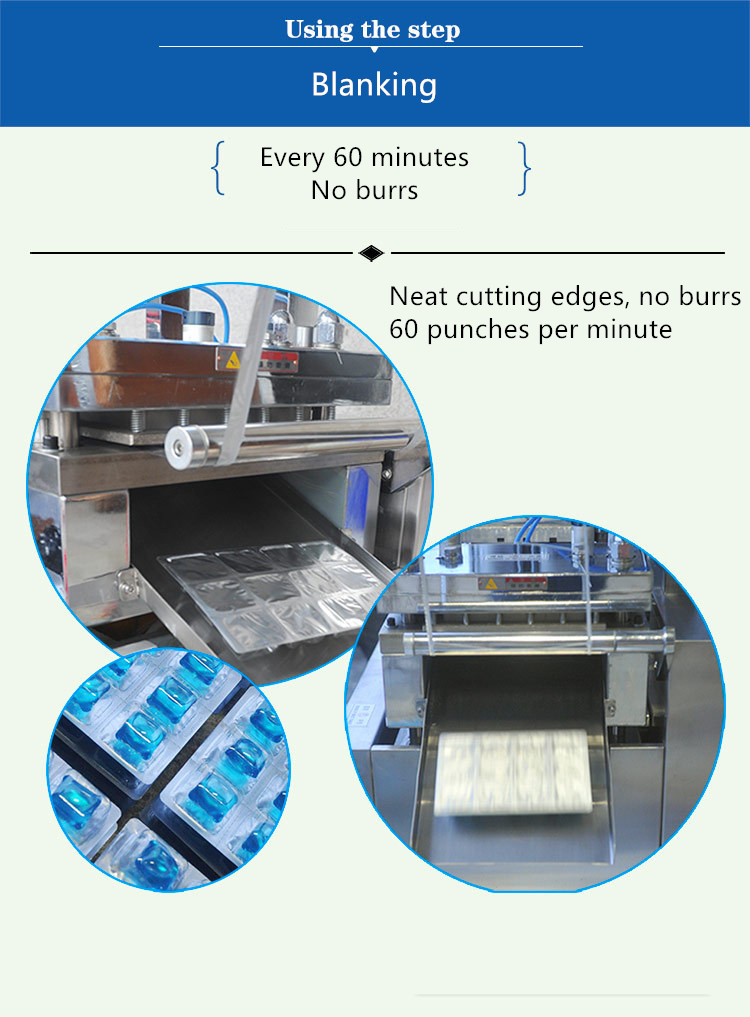

Production Process

Global Partnership and Experience

Factop serves customers across multiple continents successfully. Our client base spans America, Europe, South Africa, Korea, Philippines, and Indonesia. You join a network of satisfied customers worldwide.

We understand international trade requirements thoroughly. Export documentation and shipping arrangements are handled professionally. Your equipment arrives ready for installation and operation.

Our business philosophy emphasizes integrity, innovation, cooperation, and mutual success. You receive honest advice about equipment selection. We recommend solutions that truly fit your needs.

Quality Control of Real Photos

Contact Us

Ready to enhance your packaging capabilities? Our Capsule blister packing machine delivers the reliability and performance you need. Contact our team to discuss your specific requirements. We provide detailed quotations and technical specifications promptly.

For personalized consultation and pricing information, reach out to michelle@factopintl.com today. Let's discuss how our packaging solutions can benefit your operations.

YOU MAY LIKE