pill tablet maker

Stock: Delivery time within 25 days

Certificate: Meet GMP standard

Equipment optional: Dust collector, tablet deduster and conveyor feeder

Production capacity: 45000pcs/hour

Max tablet diameter: 50mm

Pill Tablet Maker: Professional Manufacturing Solutions for Your Production Needs

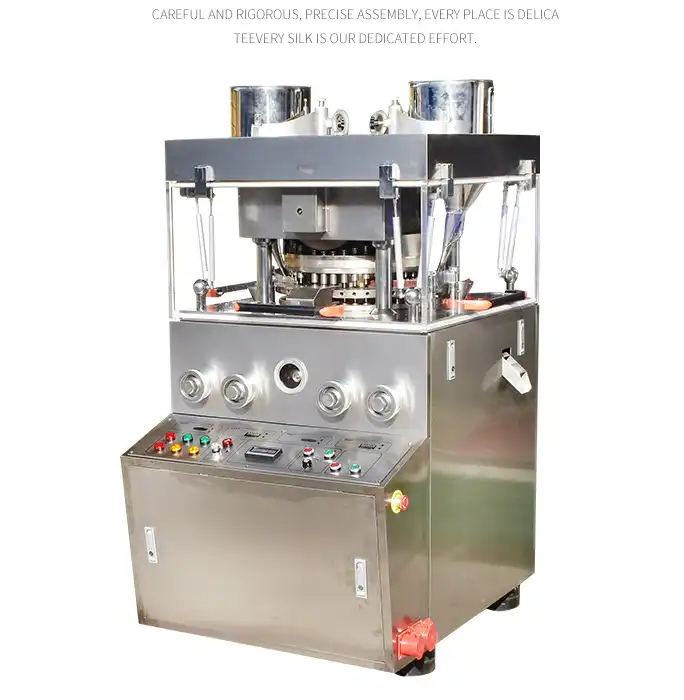

Looking for a reliable pill tablet maker to boost your production efficiency? You've come to the right place. For pharmaceutical companies, health product makers, and supplement makers, our ZPTX15D tablet press machine works very well. The cutting-edge technology in this high-tech tools makes it easy for anyone to use. Our machine makes sure that the quality is always the same, whether you're making pills for drugs, vitamins, or food supplements.

Main Parameter

| Feature | Details |

|---|---|

| Machine Type | Fully Automatic Pill Tablet Maker |

| Material | Stainless Steel, GMP Compliant |

| Capacity | Customizable (up to 500,000 tablets/hour) |

| Tablet Diameter | 6mm – 25mm (adjustable) |

| Tablet Thickness | 3mm – 20mm (adjustable) |

| Compression Force | Up to 200kN |

| Control System | PLC & Touchscreen Interface |

| Power Supply | 380V, 50Hz |

| Certifications | ISO 9001:2015, CE |

| Weight | 1.5 tons (varies by model) |

Why Choose Our Tablet Press Machine?

High Production Capacity

Up to 45,000 pieces can be made by our machine every hour. You can meet tight production plans without sacrificing quality thanks to this amazing speed. You can quickly handle big sales and keep the quality of your products the same.

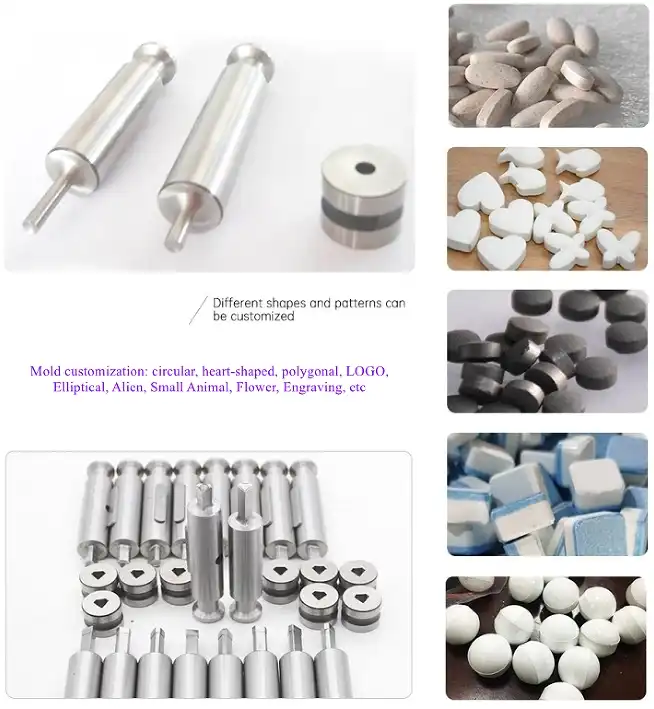

Versatile Tablet Sizes

Tablets up to 50 mm in diameter can fit in the equipment. This gives you the freedom to make different kinds of products. You have full control over the range of products you make, from small tablets for medicines to bigger pills for supplements.

GMP Certified Quality

Meeting GMP standards makes sure that your goods follow rules set by other countries. Our production process is based on strict rules for quality. You can be sure that every machine will work well in controlled settings.

Quality Control

Advanced Features That Make a Difference

Professional Design Elements

Strong building materials are used to make the ZPTX15D type. Before being put together, each part goes through a lot of tests. You will get tools that can be used continuously in tough work settings.

Optional Equipment Upgrades

Enhance your setup with additional components:

-

Dust collector system for cleaner operation

-

Tablet deduster for improved finish quality

-

Conveyor feeder for automated material handling

These upgrades optimize your workflow and reduce manual intervention.

Fast Delivery Promise

We maintain ready stock for quick shipment. Your pill tablet maker ships within 25 days of order confirmation. This rapid delivery helps you start production without lengthy delays.

Complete Support Package

Installation and Commissioning

Our expert team helps with placement on-site. We make sure that your equipment works correctly from the start. You learn everything you need to know about how to operate and maintain machines.

Quality Assurance Testing

Before being sent out, every machine goes through FAT (Factory Acceptance Testing). This thorough test shows that all features work as expected. You get full test papers along with your gear.

One-Year Spare Parts Guarantee

We include free spare parts for the first year after purchase. This comprehensive warranty protects your investment. You can operate with confidence knowing support is readily available.

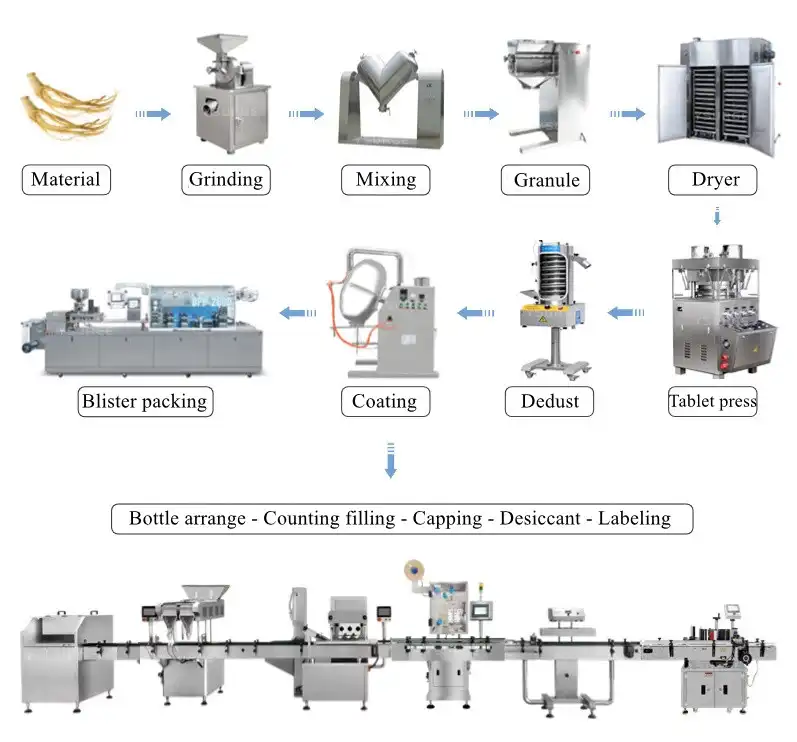

Pharmaceutical Production Process

Ideal Applications

Pharmaceutical Manufacturing

Perfect for producing medical tablets with precise dosing. The machine maintains strict tolerances required for pharmaceutical applications. You can trust consistent results batch after batch.

Health Supplement Production

Excellent for vitamin and mineral tablets. The equipment handles various formulations including herbal extracts. You can diversify your product line with confidence.

Food Industry Applications

Suitable for edible tablets and compressed food products. The GMP-certified design ensures food safety compliance. You meet regulatory requirements while maintaining production efficiency.

Application Areas

Professional Export Packaging

We use sturdy wooden boxes for international shipping. This protective packaging prevents damage during transport. Your product arrives in perfect condition regardless of destination.

Our experienced team understands international trade requirements. We handle documentation and shipping procedures efficiently. You receive seamless service from order to delivery.

Our Wearhouse, Packaging and Transportation

Our Wearhouse, Packaging and Transportation

Contact Us

Factop serves customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our multilingual team communicates effectively with international clients. We understand diverse market requirements and regulatory standards.

This extensive experience helps us provide targeted solutions. You benefit from our deep understanding of global pill tablet maker manufacturing needs.

Ready to enhance your production capabilities? Contact our team at michelle@factopintl.com for detailed specifications and pricing information. We're here to help you find the perfect manufacturing solution.

YOU MAY LIKE

_1762014629009.webp)