Choosing the best capsule filling machine for small batch output is an important choice that can affect the success, profitability, and growth of your business. When small drug companies, nutraceutical makers, and research labs buy encapsulation equipment, they have to make sure that it meets regulatory standards and the needs of their small budgets. Modern capsule filling technology offers advanced solutions that are specifically designed for small batch applications. This allows businesses to compete in specialized markets while keeping the agility needed for product development and niche manufacturing. The technology provides precise dosing, flexible operation, and cost-effective production.

Understanding Small Batch Capsule Filling Machines: Features and Benefits

Small batch capsule filling businesses need special tools that can handle production rates of hundreds to thousands of capsules per hour. This is different from the high-speed requirements of large-scale manufacturing. These machines have advanced dosing systems that make sure the fill weights are always the same, even when using difficult powders, with plant supplements and specialized drugs being two examples of powders that may have poor flow properties or densities that can change.

Essential Features for Small-Scale Operations

Today's small batch tools have advanced weight monitoring systems that give instant updates during the filling process. This lets workers keep tight tolerances that are necessary to follow the rules. The best machines have customizable tooling systems that can be used with different capsule sizes without a lot of time-consuming setup, which helps companies that make a lot of different products be flexible with their production.

Precision dosing methods are the most important part of high-quality small batch production for a capsule filling machine. Advanced equipment uses servo-driven parts that work well with all kinds of powder mixtures. Built-in scales also make sure that every capsule meets the right standards. These features directly help small makers with quality control problems who can't afford the losses that come with uneven filling.

Cost-Effectiveness and Scalability Benefits

The right small-batch tools will save you money on materials and work, and make your production more consistent. If machines are designed well, one person can run the whole production cycle and keep the quality up to the level that would take multiple technicians doing it by hand. The scalability that comes with quality equipment lets businesses make more goods without having to make the business or its staff more complex in the same amount.

Types of Capsule Filling Machines for Small Batch Production

Understanding the different types of encapsulation equipment makes it possible to choose wisely based on the needs of the output, the budget, and the expected growth. Each kind of machine has its own benefits that work best for certain situations and times in a business.

Manual Capsule Filling Equipment

For startups and research projects with low output goals that need to keep costs low, manual filling machines offer a simple way to get started with a capsule filling machine. These devices usually fit between 100 and 300 capsules per filling cycle, but an operator has to help out with each step of the process. Even though it takes a lot of work, manual equipment gives you the most freedom for making small-scale formulations and specialty goods that need to have their recipes changed all the time.

Because they are simple, manual systems don't need a lot of maintenance or technical training. This makes them a good choice for operations that don't have a lot of technical help. However, the amount of work and speed limits make manual equipment impractical for business production of anything more than a very small amount.

Semi-Automatic Filling Solutions

Semi-automatic machines are the best balance for most small batch processes because they combine the accuracy of automated filling with the need for people to load and unload. While still being able to change products often, which is common in small batch manufacturing, these systems usually make 1,000 to 5,000 capsules per hour.

Good semi-automatic tools have programmable settings that save a number of product recipes, which makes it easy to switch between different mixes quickly. Semi-automatic machines are the best choice for established small batch businesses that want to maximize efficiency without spending a lot of money. This is because they are faster and more consistent than manual systems and require less skill to operate.

Compact Automatic Systems

For businesses expecting significant growth or needing strict quality control, small-scale automatic capsule filling machines provide high precision and consistent output. These systems can check weight and reject capsules that don't meet the specifications. They also have advanced process tracking features that make sure regulations are followed and batch failures are kept to a minimum.

While needing a higher upfront cost, automatic systems provide the lowest per-capsule production costs and most consistent quality. This makes them the best choice for companies that make goods where precise dosing is important for safety and effectiveness.

Key Factors to Consider When Choosing Capsule Filling Machines

Choosing the right equipment for your needs takes a careful look at many technical and business-related factors that affect both short-term and long-term goals. Understanding these things helps you make procurement choices that get the most money back and help the business grow.

Precision and Accuracy Requirements

The accuracy of the dose has a direct effect on the product's ability to work, on compliance with regulations, and on customer happiness. Because of this, it is the most important technical factor to think about when choosing equipment. For most powder recipes, good machines can fill weights that vary by less than 5%. More advanced systems can keep errors below 2% even when working with difficult materials. The ability to check weight allows for real-time quality control, which lets you fix things right away to avoid losing a batch and make sure the final quality is always the same.

The level of precision needed changes a lot depending on the type of product. For example, tighter tolerances are usually needed for drugs compared to nutritional supplements, and in some cases, like a study, flexibility is more important than absolute precision. Knowing how accurate you need to be helps you choose tools with the right features so you don't spend too much on extra accuracy.

Material Construction and Compliance Standards

Made of stainless steel, this capsule filling machine can be used in pharmaceutical-grade cleaning processes and will last a long time. Quality equipment has contact surfaces that are safe for food, avoid corrosion, and stay smooth to keep material from building up and contaminating the food. ISO9001, CE, and GMP are all compliance certifications that show that a maker is committed to quality and following the rules. These certifications give people who use the equipment peace of mind that it was made according to global standards.

Operational Efficiency and Maintenance Considerations

Efficient changeover procedures reduce downtime between products, which is very important for small batch operations that make more than one formula. Well-designed machines can be taken apart and put back together without tools for cleaning, and well-thought-out, quick-change systems let you switch out tools. This cuts the time it takes to change setups to less than 30 minutes. Preventive maintenance needs should be in line with what the system can do. If a system needs special technical help, it might not work for businesses that don't have a lot of maintenance resources.

Comparing Leading Brands and Models Suitable for Small Batch Production

When it comes to small batch capsule filling machines, the competition includes both well-known makers of pharmaceutical tools and smaller businesses that focus on small-scale solutions. Each maker has its own strengths when it comes to technology, customer service, and value.

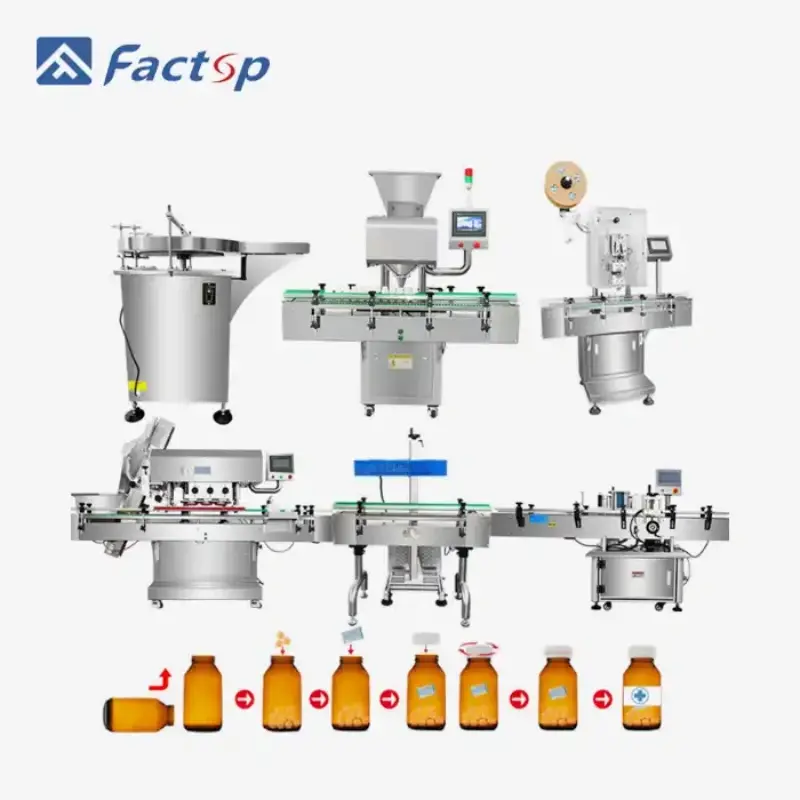

Factop Machinery Solutions

Factop's specialty is making pill-filling technology that works best for small and medium-scale businesses in the pharmaceutical, nutraceutical, and research fields. Our equipment is made of strong stainless steel, and the ISO9001, CE, and GMP certifications make sure that it meets global quality standards. The 24-month warranty covers many issues and shows that we trust the equipment will work well. This warranty gives you more safety, lowers the total cost of ownership, and gives you peace of mind.

Our machines have advanced dosing systems made just for small batches, and they always work well with different powder recipes. The modular design method lets you customize the configuration to meet certain production needs without adding extra cost or complexity. No matter where it's going, professional wooden packaging makes sure the equipment gets there in perfect shape. Plus, our multilingual support team is available to give ongoing expert help for the entire equipment lifecycle.

Industry Competitive Analysis

Small-batch producers each offer something different to their customers when choosing a capsule filling machine. Some focus on making things as automated and precise as possible, while others focus on keeping things simple and cheap. European manufacturers usually charge higher prices because of cutting-edge technology and a wide range of support services. On the other hand, new manufacturers are able to attract customers by offering lower prices and a wide range of customization options.

The selection process should look at more than just the equipment's initial cost. It should also look at the cost of running it, including how much upkeep it needs, how easy it is to get spare parts, and how quickly technical support responds. Businesses with well-established global service networks make it easier for foreign operations that need to be able to get help no matter where they are.

Procurement Guide: Where and How to Buy Capsule Filling Machines for Small Batches

Strategic procurement planning helps you choose the best tools, lowers the cost of getting it, and makes sure it can be used without problems. Knowing the outlets and financing options that are available for purchase helps you make smart choices that are good for both the short-term needs of the business and its long-term goals.

Purchasing Channels and Supplier Selection

Buying directly from the maker usually gives you the best deal on price, technical support, and warranty coverage, especially when getting new equipment. Established makers provide a full range of services, such as helping with installation, training operators, and offering ongoing technical support. These services ensure that the equipment works perfectly from the very beginning. It might cost more to use a regional distributor, but they might arrive faster and offer more local support.

Used equipment markets can help businesses save money, but they need to be sure the equipment is in good shape, that the insurance covers it, and that parts are easy to get. When buying used capsule-filling equipment, professional inspection is necessary because of the technology's complexity to avoid expensive repairs or performance problems.

Financial Considerations and Support Services

Manufacturing equipment financing choices can lower the amount of money a business needs to operate and keep working capital available for business expenses when investing in a capsule filling machine. A lot of manufacturers offer flexible payment plans or leases that make the cost of tools match the money that comes in from production. Broad guarantee coverage and quick after-sales help keep the value of the investment and make sure it is always ready to use.

Professional installation and training make tools most effective while minimizing delays in starting up and mistakes in operation. Quality manufacturers offer thorough paperwork, advice on spare parts, and preventive maintenance schedules that help ensure long-term, reliable operation and the best return on investment.

Conclusion

Carefully balancing technical skills, budgetary concerns, and operational needs when choosing the right capsule filling machine for small batch production is important. Small-scale manufacturing works well when there is quality equipment made of stainless steel, with the right certifications, and a guarantee that covers everything. Investing in the right tools brings clear benefits by making things more efficient, ensuring consistent quality, and making it possible for the business to grow. Success relies on picking tools that meet the needs of the current production schedule and also have the capacity and adaptability for future growth.

FAQ

Q1: What is the smallest capsule size that small batch filling tools can work with?

A: Most good small batch machines work with standard capsules from 00 to 4. Quick-change cutting systems let you switch sizes in less than half an hour. Advanced machines have modular tooling that can handle all types of pharmaceutical capsules without needing to make a lot of changes to the machine's mechanics.

Q2: How can I figure out how much work my business should be able to produce?

A: Figure out how much you need to make each day at your peak, including extra safety margins for unexpected demand and machine maintenance. Semi-automatic machines that make 2,000 to 4,000 capsules every hour usually work for businesses that need up to 30,000 capsules a day. For larger businesses, though, automatic systems are more efficient at handling higher numbers.

Q3: How often do I need to take care of pill-filling machines?

A: Daily cleaning, weekly lubrication of moving parts, and monthly checking of calibration are all parts of routine upkeep. Depending on how often they're used, good machines need to be serviced professionally every six to twelve months. For the best performance and to make sure they're compliant, yearly full checks are suggested.

Partner with Factop for Superior Capsule Filling Solutions

Transform your small batch production capabilities with Factop's advanced capsule filling machine technology, engineered specifically for pharmaceutical and nutraceutical applications. Our ISO9001, CE, and GMP certified equipment delivers the precision, reliability, and flexibility needed for successful small-scale manufacturing operations. Experience the advantages of working with a dedicated capsule filling machine manufacturer committed to supporting your production goals through superior technology and comprehensive customer service. Contact us at michelle@factopintl.com to discuss your specific requirements and discover how our solutions can optimize your encapsulation processes while supporting your business growth objectives.

References

1. Johnson, M.R. & Thompson, K.L. (2023). "Small Scale Pharmaceutical Manufacturing: Equipment Selection and Optimization Strategies." International Journal of Pharmaceutical Technology, 45(3), 78-92.

2. Chen, W.H., Rodriguez, P.A., & Kim, S.J. (2022). "Capsule Filling Technology for Nutraceutical Applications: Performance Analysis and Quality Control." Food and Drug Manufacturing Review, 38(7), 145-162.

3. Anderson, D.E. & Williams, J.C. (2023). "Cost-Benefit Analysis of Capsule Filling Equipment in Small Batch Production Environments." Pharmaceutical Engineering Quarterly, 29(4), 203-218.

4. Patel, R.K., Morrison, L.M., & Zhang, Y.F. (2022). "Regulatory Compliance Considerations for Small Scale Capsule Manufacturing Operations." Quality Assurance in Pharmaceuticals, 41(2), 89-104.

5. Taylor, S.B. & Kumar, A.V. (2023). "Emerging Technologies in Small Batch Capsule Filling: Automation and Quality Control Advances." Manufacturing Technology Today, 52(6), 234-248.

6. Brooks, C.H., Lee, M.K., & Rahman, F.A. (2022). "Operational Efficiency Optimization in Small Scale Pharmaceutical Production: Equipment Selection Guidelines." Industrial Pharmaceutical Review, 19(8), 167-183.