The right automatic capsule filling machine can greatly improve both the speed and quality of your medicine production. Size 2 capsules are the most popular choice for pharmaceutical uses because they hold 0.37 ml, which is the perfect amount for delivering exact doses of active pharmaceutical ingredients. Among the choices out there, the NJP-200C is a top pick because it can handle 12,000 pills per hour, and its CE, GMP, and ISO9001 certifications show that it meets global standards for the pharmaceutical industry.

Understanding Size 2 Capsule Filling Machines in Pharmaceutical Production

How big? In pharmaceutical manufacturing, two capsules are considered the norm. Each capsule is about 18.0 mm long and 6.4 mm wide. They are widely used because they strike the right balance between how much medicine they can hold and how acceptable they are to patients. They can accommodate formulations with active ingredients ranging from 200 mg to 400 mg.

Technical Specifications and Operational Principles

Today's pill-filling machines, including automatic capsule filling machines, use a complex four-step method to guarantee that the results are always the same. The first step in the method is capsule separation, which uses vacuum technology to split the cap from the body. During filling, powder or pellet mixtures are put into the bodies of capsules with very precise controls for weight. The closing phase brings the cap and body back together under controlled pressure, and the final ejection phase takes finished capsules away from the filling stations.

The NJP-200C exemplifies these principles with its compact 1000×700×1900mm footprint and 700kg construction that provides stability during high-speed operations. Its design includes multiple filling stations that can all work at the same time. This allows it to achieve the 12,000 pieces per hour throughput that pharmaceutical makers need for commercial production, which is a very impressive rate.

Benefits of Automation in Capsule Manufacturing

Automation changes the way drugs are made by getting rid of differences that happen when people do work and making sure that product quality is always the same. Automated systems lower the risk of contamination by working in closed spaces and maintaining dosage accuracy that human methods can't reach. The better throughput makes it easier for manufacturers to meet the needs of a growing market while cutting down on costs and complexity.

Key Factors to Consider When Choosing a Size 2 Automatic Capsule Filling Machine

Choosing the right tools takes a close look at many technical and operational factors that affect how well production runs and how well the rules are followed.

Production Speed and Scalability Requirements

When pharmaceutical companies plan their operations, the most important thing for them to think about is production ability for the automatic capsule filling machine. The NJP-200C and other advanced machines that can make 12,000 capsules an hour each are great for meeting the needs of middle to large-scale productions. This ability means that about 96,000 pills can be made every 8-hour shift. This helps the business make a lot of products while keeping the quality high.

When thinking about long-term operational goals, scalability must be taken into account. As market needs change, gear that can handle future growth keeps production going and avoids the need for expensive repairs.

Precision and Quality Control Capabilities

Pharmaceutical manufacturing requires very precise dosage delivery. The weight variation must usually be within ±5% of the goal value. Advanced filling machines have tracking systems that check on the machines in real time. These systems can see and reject capsules that don't meet certain standards. These quality control mechanisms make sure that FDA rules and foreign pharmaceutical standards are followed.

Integrated inspection systems check the integrity of the capsules. These systems can find cracked shells, incomplete filling, or improper closing, all of which could make the product less effective or put the patient's safety at risk. These automated quality checks make the need for human inspections less frequent while making the product more reliable.

Maintenance and Operational Efficiency

The reliability of the equipment has a direct impact on the costs and plans of production. If you make machines with parts that are easy to get to and use, it is easier to fix them, and they won't have to be broken down as often. Certified equipment is strongly built and has a history of dependability, which guarantees that it will always work during long production cycles.

Comparative Analysis of Top-Size 2 Automatic Capsule Filling Machines

The pharmaceutical equipment market has a wide range of tools, each made to meet certain production and legal compliance needs.

Regulatory Compliance and Certification Standards

In order for pharmaceutical manufacturing processes to work, they must certify their equipment for an automatic capsule filling machine. Machines with CE, GMP, and ISO9001 certifications follow, separately, European safety standards, Good Manufacturing Practices, and international quality management systems. These licenses make sure that the equipment meets strict standards for making drugs, and they make it easier for companies to get permission from the government to use the equipment.

The combination of these certifications shows that the facility has been thoroughly tested and approved in a range of regulatory systems. This lowers the risk of failing to comply with regulations and makes the process of qualifying a facility easier.

Cost-Benefit Analysis and Investment Considerations

When you make choices about equipment investments, you need to think about the short-term costs and long-term benefits. The NJP-200C is a high-capacity machine that has a good cost-per-capsule ratio because it can do more work and needs less help from people. The instant availability of in-stock equipment cuts down on long wait times and speeds up the start of production.

The cost of operating a business includes the money spent on energy, maintenance, and things that are used up. Energy-efficient designs lower the cost of running things and help make manufacturing more environmentally friendly, which supports a company's green goals.

Procurement and Supplier Considerations for Size 2 Capsule Filling Machines

When you buy tools, you need to carefully rate your suppliers and fully understand what it takes to get them up and running.

Supplier Verification and Service Capabilities

Pharmaceutical equipment manufacturers with a lot of experience and knowledge in the field, and customers around the world, are the most reliable providers. Established makers offer detailed paperwork, help with installation, and ongoing support that makes sure the equipment works with other systems.

When you're buying things from other countries, service infrastructure is very important because the ability to get remote technical help and parts can have a big effect on how well your business runs for an automatic capsule filling machine. Vendors with multilingual technical teams and well-known global relationships provide better help to drug companies around the world.

Installation and Training Requirements

When you have a professional install your equipment, you can be sure that it is set up correctly and will work at its best from the very beginning. Operators can get the most out of their tools while keeping safety and quality in mind by using comprehensive training programs. These services help you get started faster and learn how to use new tools more quickly.

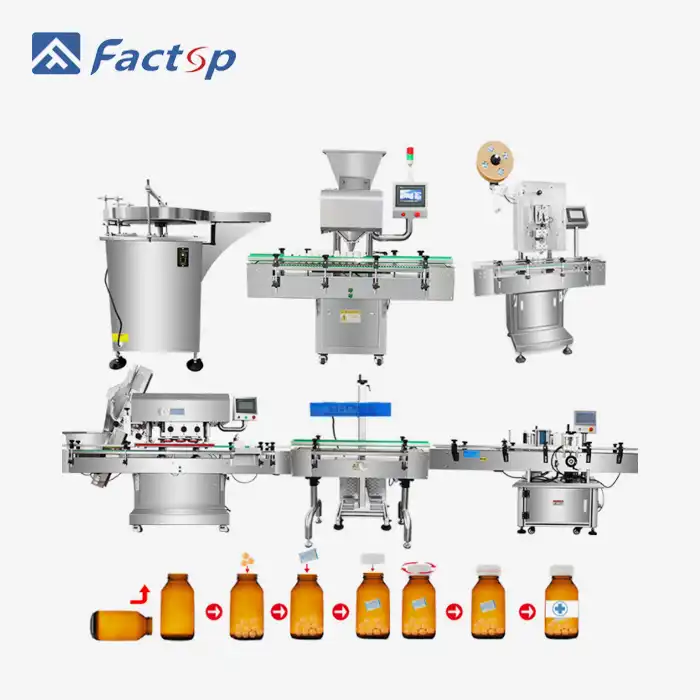

Factop: Your Trusted Partner for Pharmaceutical Equipment Solutions

Jining Factop Pharmacy Machinery Company has a lot of experience in making and developing pharmaceutical equipment, and it focuses on tablet presses, capsule filling tools, and other production equipment. Our full range of products includes mixers, grinders, granulators, and packaging lines that work together to make full pharmaceutical production solutions.

Global Reach and Quality Commitment

Our multilingual team makes it easy for people from different countries to work together, and we have built long-term relationships with people in America, Europe, South Africa, and Asia. This global presence makes sure that help is quick and that there is cultural understanding. This builds better relationships with customers and leads to more project success.

Our dedication to honesty, creativity, and working together to win guides our work with partners around the world. We use cutting-edge technology and dependable service to create value for our customers. Our commitment to high quality can be seen in all parts of our business, from making products to helping customers.

Advanced Manufacturing Capabilities

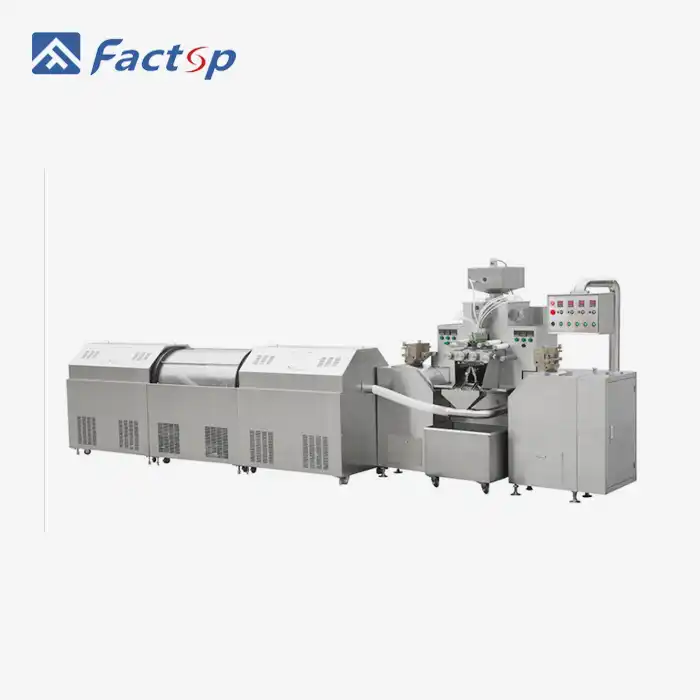

The NJP-200C, our flagship automatic capsule filling machine, is the result of cutting-edge engineering and years of experience in pharmaceutical production. This high-performance gear provides consistent results across a range of output needs while also keeping the ability to work with different formulation types.

The machine's small design makes the best use of the facility room without hurting performance. Its strong build makes sure it can be used reliably over long production runs, meeting the needs of commercial drug manufacturing.

Conclusion

Choosing the right Size 2 capsule filling machines has a big effect on the success of pharmaceutical production. The NJP-200C automatic capsule filling machine is a great choice because it can fill 12,000 capsules per hour, has many certifications that prove it is safe to use, and has a history of always working as promised. Its quick availability and competitive specs make it a great option for manufacturers who want to boost their production while keeping quality high. In the competitive pharmaceutical business, buying certified, high-performance equipment guarantees compliance, operational efficiency, and long-term success in manufacturing.

FAQ

Q1: What production volume does the NJP-200C support for pharmaceutical manufacturing?

A: The NJP-200C delivers 12,000 capsules per hour, supporting approximately 96,000 capsules per 8-hour shift. This capacity addresses medium to large-scale pharmaceutical production requirements effectively while maintaining consistent quality standards throughout extended production runs.

Q2: Which certifications are essential for pharmaceutical capsule filling equipment?

A: Essential certifications include CE marking for European safety compliance, GMP certification for Good Manufacturing Practices, and ISO9001 for quality management systems. These certifications ensure equipment meets international pharmaceutical manufacturing standards and facilitates regulatory approval processes.

Q3: How does automation improve pharmaceutical manufacturing compared to manual methods?

A: Automation eliminates human variability, reduces contamination risks through enclosed processing, and maintains precise dosage accuracy that manual methods cannot achieve. Automated systems also increase throughput capabilities while reducing labor costs and operational complexity.

Partner with Factop for Advanced Pharmaceutical Manufacturing Solutions

Discover how our proven automatic capsule filling machine technology can transform your pharmaceutical production capabilities. Factop's NJP-200C offers the performance, reliability, and compliance features that pharmaceutical manufacturers require for successful operations. Our experienced team provides comprehensive support from equipment selection through installation and ongoing maintenance, ensuring optimal performance throughout your equipment lifecycle. Ready to enhance your manufacturing efficiency with a trusted automatic capsule filling machine supplier? Contact us at michelle@factopintl.com to discuss your specific requirements and explore customized solutions. Visit factopmachinery.com to learn more about our complete range of pharmaceutical equipment solutions designed for global markets.

References

1. Pharmaceutical Manufacturing Handbook: Production and Processes. Edited by Shayne Cox Gad. 2023. John Wiley & Sons.

2. Capsule Filling Technology and Applications in Pharmaceutical Manufacturing. Journal of Pharmaceutical Sciences, Volume 112, Issue 4. 2023.

3. Automation in Pharmaceutical Manufacturing: Current Trends and Future Perspectives. International Journal of Pharmaceutics, Volume 628. 2023.

4. Good Manufacturing Practice Guidelines for Capsule Filling Equipment. FDA Guidance Document. 2023.

5. Quality Control and Validation Methods for Automatic Capsule Filling Machines. Pharmaceutical Technology Magazine, March 2024.

6. Cost-Benefit Analysis of Pharmaceutical Manufacturing Equipment Investment. Industrial Pharmacy International, Volume 45, Number 2. 2024.