Tablet die press

Punch die No. : 5

Max pressure: 60KN

Material: Stainless steel + Iron steel

Function: With counter

Type: Automatic pill press

Tablet Die Press ZP-5B: Professional Pharmaceutical Manufacturing Solution

Looking for a reliable tablet die press for your pharmaceutical production needs? The ZP-5B product from Factop delivers exceptional performance and precision. This automatic pill press combines advanced engineering with user-friendly operation. Built with premium stainless steel and iron steel construction, it ensures durability and meets strict pharmaceutical standards. Your manufacturing process will benefit from its consistent output and reliable performance in various production environments.

Main Parameter

| Feature | Description |

|---|---|

| Model | ZP-5B tablet die presses |

| No. of station | 5 sets |

| Max production capacity | 12600pcs/hour |

| Max press diameter | 20mm |

| Max tablet thickness | 6mm |

| Max pressure | 60KN |

| Motor power | 220/380V, 2.2kw |

| Dimension | 620*480*1020mm |

| Weight | 220kg |

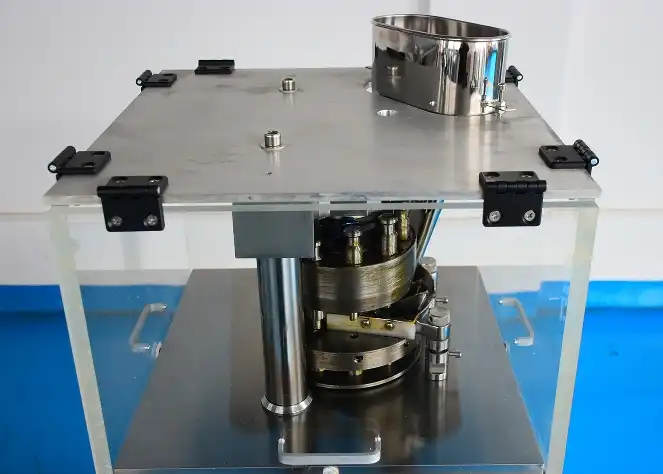

Some details of tablet die press machine

Why Choose Our Automatic Tablet Press Machine?

The ZP-5B stands out in today's competitive pharmaceutical machinery market. You get a machine that handles diverse tablet formulations with ease. Its 60KN maximum pressure capability ensures proper tablet compression every time.

This machine features an integrated counter system. You can track production quantities accurately without external monitoring equipment. The automatic operation reduces manual intervention and minimizes production errors.

Your investment is protected by our comprehensive one-year spare parts warranty. This coverage gives you peace of mind and reduces unexpected maintenance costs.

Technical Specifications That Matter

- Model: ZP-5B

- Punch Die Numbers: 5 stations

- Maximum Pressure: 60KN

- Construction Materials: Stainless steel and iron steel

- Operation Type: Fully automatic

- Built-in Features: Digital counter system

The 5-punch configuration provides optimal balance between production speed and tablet quality. You achieve consistent results whether producing small batches or larger quantities.

The mixed material construction offers the perfect combination of corrosion resistance and structural strength. Stainless steel components contact your product directly, ensuring contamination-free operation.

Main Real Photos Show

Applications Across Multiple Industries

This versatile tablet die press serves various sectors effectively. Pharmaceutical factories rely on it for medication production. Health product manufacturers use it for supplement tablets. Hospital preparation rooms benefit from its compact design and reliable operation.

Food factories incorporate it into their production lines for dietary supplements. Chemical plants utilize it for specialized tablet formulations. The machine adapts to different powder characteristics and binding agents.

Your specific industry requirements are met through adjustable pressure settings and interchangeable tooling options.

Application and Finished Products

Quality Assurance and Compliance

Factop maintains GMP-certified manufacturing facilities. This certification ensures every machine meets international pharmaceutical standards. Your production facility benefits from equipment that passes regulatory inspections.

Quality Control

Each unit undergoes Factory Acceptance Testing (FAT) before shipment. This comprehensive testing validates performance parameters and operational reliability. You receive documentation supporting your facility's validation requirements.

Export packaging uses professional wooden boxes. This protection ensures your equipment arrives in perfect condition regardless of shipping distance.

Professional Installation and Support Services

On-site installation and commissioning services are available worldwide. Our experienced technicians ensure proper setup and operator training. This service minimizes downtime and accelerates production startup.

Our multilingual technical team provides ongoing support throughout your equipment lifecycle. You have access to expertise when you need it most.

Training covers operation procedures, maintenance schedules, and troubleshooting techniques. Your operators gain confidence and competency quickly.

Some feedback from our customers

Global Manufacturing Excellence

Factop's international presence spans America, Europe, South Africa, Korea, Philippines, and Indonesia. This global reach demonstrates our commitment to customer satisfaction worldwide.

Our experienced team understands diverse regulatory environments and cultural business practices. You work with professionals who appreciate your local market requirements.

Long-term partnerships characterize our customer relationships. We grow alongside your business and adapt to changing production needs.

Production Process

Investment Value and ROI

The ZP-5B product represents excellent value for pharmaceutical manufacturing operations. Initial investment costs are offset by reliable operation and minimal maintenance requirements.

Reduced labor costs result from automated operation features. You achieve higher productivity with fewer operators compared to manual alternatives.

Energy efficiency keeps operational costs manageable. The machine's design optimizes power consumption without compromising performance.

Workshop and Packaging

Contact Us

Ready to enhance your pharmaceutical manufacturing capabilities? Contact our team to discuss your specific requirements. We provide detailed quotations and technical consultations.

Our experts help you select the optimal configuration for your production goals. You receive personalized recommendations based on your tablet specifications and volume requirements.

Transform your tablet production with the reliable ZP-5B tablet die press. Contact michelle@factopintl.com today to begin your journey toward enhanced manufacturing efficiency and superior product quality.

YOU MAY LIKE