The production capacity, sorting accuracy, legal compliance, and long-term operational costs must all be carefully considered when selecting the right Capsule Sorter Machine for the production of nutraceuticals and dietary supplements. The perfect machine should be able to work with your current production line without any issues, and it should be able to do quality control that meets the FDA and foreign standards every time. Newer optical sorting technologies and automated systems have made modern capsule sorting machines much more accurate and efficient than ever before. These improvements help makers in the pharmaceutical, nutraceutical, and dietary supplement industries.

Understanding Capsule Sorter Machines: Key Features and Technologies

Capsule sorting technology has come a long way from simple machines to complex automatic systems that change the way quality control is done. Modern capsule inspection systems use very precise optical sensors, AI, and exact mechanical parts to find and remove defective goods with amazing accuracy.

Advanced Sorting Technologies and Detection Capabilities

Today's capsule sorting machines use multiple ways of checking to make sure that all quality control is done. Capsules are sorted by optical systems that check how they look, how consistent their color is, and how intact their surfaces are, and by weight-based systems that find capsules with improper fill levels. High-resolution cameras take very detailed pictures at processing speeds of up to 300,000 pieces per minute. This allows defects to be found in real time, which is better than having people do the work by hand.

By looking at trends in historical data and changing detection settings on their own, machine learning algorithms and Capsule Sorter Machine keep getting better at sorting. This new piece of technology helps keep high-quality standards that are needed in pharmaceutical-grade manufacturing settings. It does this by lowering the rate of false rejections.

Integration with Capsule Processing Equipment

Capsule sorting systems that work well with capsule filling machines, polishing equipment, and packing systems are production lines that work with them. The dual-head setup used in many industrial models lets several lines of capsules be processed at the same time. This speeds up the work while keeping quality standards steady.

Core Criteria for Choosing the Best Capsule Sorter Machine

Choosing the best sorting tools involves carefully considering many technical and operational factors that have a direct effect on how quickly and how well products are made. Understanding these factors helps buying teams make good choices that are in line with both present needs and plans for future growth.

Production Capacity and Throughput Requirements

The amount of production affects the needed sorting ability and the choice of equipment, which is very important for the Capsule Sorter Machine. Manufacturers that make a lot of products benefit from machines that can process 300,000 capsules a minute. On the other hand, smaller businesses might value flexibility and cost-effectiveness more than maximum output. Looking at current production needs and expected growth when buying new tools makes sure that it will help the business reach its goals in the long run.

When you figure out the optimal sorting speed, think about the need for surge capacity and peak output times. The ability to handle standard capsule sizes from #00 to #5 makes the equipment useful for a range of different products that are popular in the nutraceutical industry.

Quality Control Standards and Regulatory Compliance

Regulatory compliance is still very important in the production of pharmaceuticals and nutraceuticals. This makes the approval standard a very important factor when choosing something. When equipment has CE, FDA, and ISO9001 certifications, it shows that it meets foreign quality standards and makes it easier for businesses to get permission to sell their products in markets around the world.

Validation features like batch tracking, statistical reporting, and audit trail functions for the Capsule Sorter Machine help meet the standards of Good Manufacturing Practice (GMP) and make it easier to keep quality assurance records.

Operational Efficiency and Maintenance Considerations

How reliable the equipment is directly impacts the amount of time output can happen and the overall cost of owning it. The machines need very little compressed air (0.15MPa) and have a small size (800×840×1560mm). This makes the best use of the building and lowers the cost of running the business. Predictive maintenance features and easy-to-use part design lower downtime and extend the life of equipment.

Comparison of Leading Capsule Sorter Machines for Nutraceuticals

The capsule sorting tools market has a wide range of options, from basic systems to high-tech platforms used in factories. Understanding the differences between machine types helps producers pick out the right tools for their particular needs and quality standards.

Automatic vs. Semi-Automatic Sorting Systems

For large-scale nutritional production, fully automatic capsule sorting systems are better than semi-automatic ones because they are more consistent and can sort more capsules in less time. These systems combine mechanical systems for moving parts with high-tech cameras to sort over 99.9% correctly while working with different types of capsules at the same time.

Semi-automatic systems and the Capsule Sorter Machine are a cheap way for smaller makers or research labs that need flexible organizing options to avoid the difficulty of fully automated platforms. The amount of work that needs to be done, how perfect it needs to be, and the skilled workers that are on hand all affect the decision about how much technology to use.

Specialized Features for Nutraceutical Applications

Nutraceutical capsules are hard to sort because the fill materials, capsule shells, and product mixes are all different. Advanced sorting systems meet these needs by using customizable detection settings, multiple ways to reject unsuitable items, and features that keep the products clean during the sorting process.

Capsule cleaning that also sorts capsules is a great way to make sure everything is done right because it removes dust, makes capsules look better, and gets rid of capsules that are broken all in one step. This integration lowers the need to handle things, reduces the risk of contamination, and raises the general quality of the product.

Practical Guide to Capsule Sorter Machine Operation and Maintenance

To get the most out of your equipment, you need to follow a set routine and fix things before they break. This will keep the quality of your work high and make your equipment last longer. If these practices are done correctly, they will have a big effect on both the return on investment and the speed of the operations.

Startup Procedures and Calibration Protocols

To use a machine properly, you need to follow a long list of steps to make sure everything is working right. Calibration protocols set the standard performance levels for optical sensors, mechanical parts, and rejection systems. They also keep a copy of the first settings for quality assurance files.

Regular calibration with approved reference standards makes sure that accuracy and quality standards are met. More advanced systems that can automatically calibrate themselves save time on setup and keep the same level of performance across all work shifts.

Preventive Maintenance and Performance Optimization

Scheduled maintenance programs keep the equipment, including the Capsule Sorter Machine, from unexpectedly stopping and ensure that sorting performance stays at the best level for the entire working life of the equipment. To avoid causing too much trouble, routine cleaning, part inspection, and wear piece replacement should be done in line with the production plan.

Performance tracking systems keep an eye on important data like sorting accuracy, throughput rates, and rejection percentages. This allows companies to make decisions that are based on data. Before product quality or production efficiency is affected, trending analysis spots slow drops in performance.

Procurement Strategy: How to Buy the Right Capsule Sorter Machine

To come up with a good procurement plan, you need to look closely at what your suppliers can do, how your tools will be used, and the total cost of ownership, which includes more than just the price you pay. When you buy tools, you should think about both your short-term and long-term goals.

Supplier Evaluation and Selection Criteria

Supplier assessment includes technical knowledge, service skills, and manufacturing quality that help make sure the equipment is used and continues to work. Established makers with proven track records in pharmaceutical equipment make people feel good about the reliability and compliance of their products.

The amount of local service, the number of spare parts on hand, and the speed of technical help have a big effect on equipment uptime and the cost of doing business. Suppliers that give full training programs make sure that operators learn how to do their jobs well, which also helps production stay efficient even when people are learning.

Financial Considerations and ROI Analysis

Total cost of ownership analysis looks at the cost of the technology itself, installing it, training people to use it, and taking care of it over the course of its expected service life. The cost of running something, which affects its ability to make money in the long run, is due to the energy it uses, the supplies needed, and the people who operate it.

A business can grow with the help of financing choices, warranty terms, and upgrade pathways for the Capsule Sorter Machine, which also protect the money that was first put into the business. When equipment suppliers offer to let customers pay in different ways and promise that their products will work, they show that they trust their products and help customers avoid taking on too much debt.

Conclusion

Finding the best Capsule Sorter Machine means finding a balance between technical details, how it will be used, and costs in order to get the best long-term value. In a wide range of factory settings, modern sorting systems have amazing features that help make products better, streamline operations, and ensure compliance with rules. Manufacturers can lower their prices and get better control of their quality when they use advanced technologies like AI, optical inspection, and predictive maintenance. A close look at the supplier's skills, the equipment's features, and the total cost of ownership makes sure that the implementation works out, helps the business grow, and keeps its edge in the ever-changing nutraceutical market.

FAQ

Q1: What's the difference between a capsule sorter and a capsule filler machine?

A: Capsule sorters check for quality by looking at and removing capsules that are broken after they are filled. At the same time, capsule fillers are made to fill empty capsules with pellets, grains, or powder. Fillers are in charge of dosing and encapsulation, while sorters use sensors and optical systems to find flaws like cracks, color changes, or incorrect fill levels. A lot of today's systems combine the two tasks so that production can run more smoothly.

Q2: How do I find the right level of sorting accuracy for my supplement production line?

A: The accuracy needed for sorting depends on your product details, rules, and quality goals. Pharmaceutical-grade goods usually need at least 99.9% accuracy, but dietary supplements might be okay with a little less. When you set accurate standards, think about how much error you can take, how much quality your customers expect, and how closely you need to follow the rules.

Q3: Is it possible to add new tech to my current capsule sorter machine?

A: A lot of today's sorting systems have flexible designs that make it easy to add on new technologies like better AI algorithms, sensors, and systems that help with vision. But whether or not you can upgrade relies on how old your current equipment is built. Talk to your equipment seller about whether or not you should install new parts on your old equipment or buy new equipment. Consider how each option might improve performance and how much each option would cost.

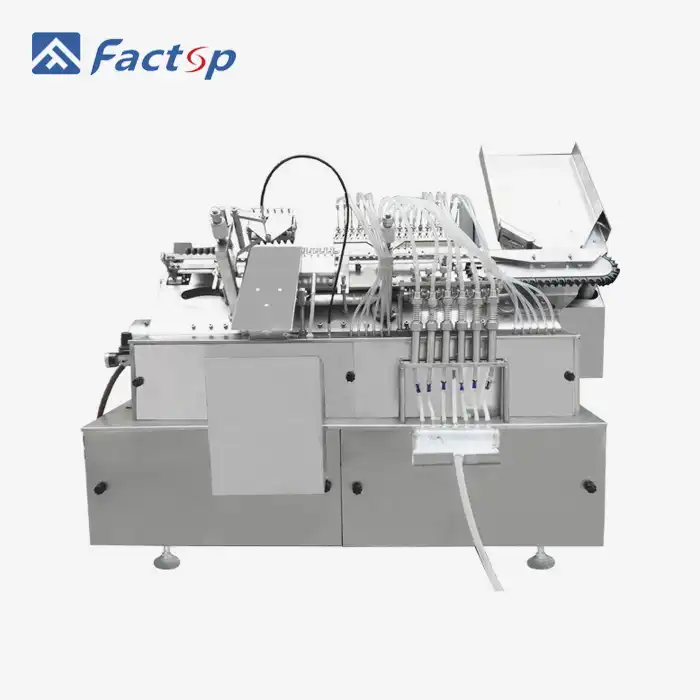

Partner with Factop for Advanced Capsule Sorting Solutions

Ready to enhance your nutraceutical manufacturing with precision capsule sorting technology? Factop offers state-of-the-art capsule polishing machines with integrated sorting capabilities, delivering 300,000 pieces per minute throughput with CE, FDA, and ISO9001 certifications. Our dual-head systems accommodate all standard capsule sizes while maintaining pharmaceutical-grade quality standards. As a trusted Capsule Sorter Machine manufacturer, we provide comprehensive support from equipment selection through installation and ongoing maintenance. Contact us at michelle@factopintl.com to discuss your specific requirements and discover how our advanced sorting solutions can optimize your production efficiency.

References

1. Smith, J.A. (2023). "Advanced Capsule Sorting Technologies in Pharmaceutical Manufacturing." International Journal of Pharmaceutical Engineering, 45(3), 78-92.

2. Rodriguez, M.C. & Chen, L. (2023). "Quality Control Systems for Nutraceutical Manufacturing: A Comprehensive Review." Journal of Dietary Supplement Quality Assurance, 18(2), 134-149.

3. Thompson, R.K. (2022). "Automated Inspection Systems in Capsule Manufacturing: Performance Analysis and Selection Criteria." Pharmaceutical Technology International, 29(4), 56-71.

4. Williams, S.B. et al. (2023). "Cost-Benefit Analysis of Capsule Sorting Equipment in Small to Medium Scale Manufacturing." Manufacturing Economics Quarterly, 12(1), 23-38.

5. Kumar, A. & Peterson, D. (2022). "Regulatory Compliance Considerations for Capsule Processing Equipment." FDA Regulatory Review, 31(6), 112-127.

6. Anderson, K.M. (2023). "Integration Strategies for Capsule Sorting Systems in Modern Production Lines." Process Engineering Today, 41(8), 89-104.