Nutraceutical makers who want to make production more efficient while also cutting costs must choose the right Soft Gelatin Capsule Filling Machine. As the global nutraceutical market grows—worth about $454 billion in 2023—it has become even more important to find safe ways to encapsulate these products. These days, capsule filling machines have to produce uniform quality and be able to work with a wide range of formulations, from fish oil pills to vitamin complexes. Manufacturers can make smart investments that help the business stay profitable and competitive in the market by knowing the fine line between what machines can do, how much it costs to run them, and how many products need to be made.

Understanding Soft Gelatin Capsule Filling Machines

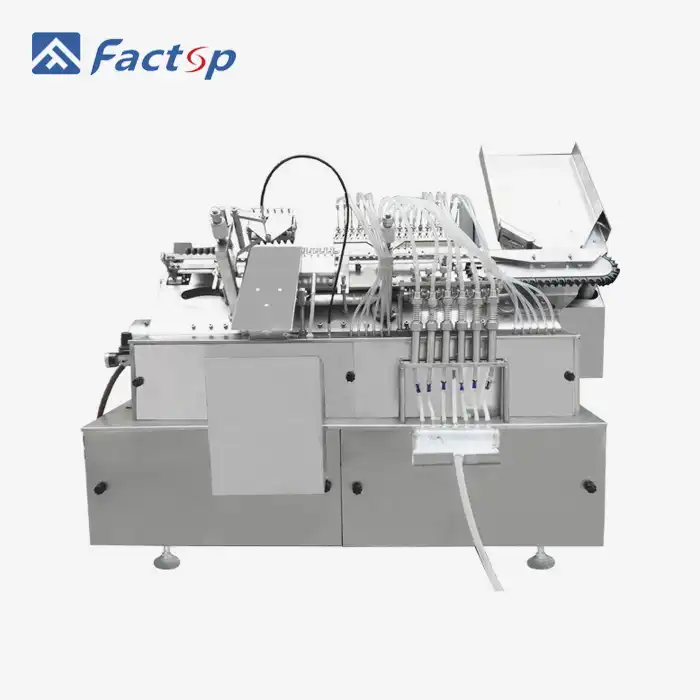

The advanced technology in soft gelatin capsule filling machines carefully encloses liquids and gels in soft capsules. These machines bring together a number of parts that work together in perfect balance to make sure the capsules they produce are always high-quality and meet strict standards set by the industry.

Core Operating Principles and Components

Gelatin sheet feeding starts the packaging process. In this step, the machine's die rollers are constantly given specially made gelatin films. Today’s precise dosing systems measure exact amounts of liquids to make sure that capsule weights and potency levels are always the same. The controlled heat and pressure used by the sealing process create hermetic capsule seals. These keep the contents safe from outside factors and keep the product stable as long as it's on the shelf.

Temperature control devices keep the best conditions for gelatin plasticity. They usually work within a small range of 37–40°C to keep the material from hardening or softening too soon. High-tech machines have sensors for real-time monitoring that automatically change settings. This keeps the product quality steady and lowers the need for help from the person running the machine.

Machine Classifications and Production Scales

From small lab machines that make 500 to 1,000 capsules an hour to huge systems that can make over 50,000 capsules an hour, there are many different kinds of equipment, including soft gelatin capsule filling machines. The HSR-60 model is an example of mid-range efficiency. With die roller measurements of 64×60mm and a capacity of 5,000 capsules per hour, it is a good choice for medium-sized businesses that need dependable performance and don't want to spend too much money.

Features That Define Cost-Effectiveness in Filling Machines

The cost-effectiveness of something goes beyond its price and includes how well it works, how often it needs to be fixed, and how productive it is over time. Smart purchasing looks at the total cost of owning property over its lifetime instead of just the cost of buying it.

Production Capacity Optimisation

When you match your machine's capacity to your real production needs, you avoid both underuse and bottleneck situations. The HSR-60 can handle 5,000 capsules per hour, which is a great help to manufacturers who work with medium-sized batches. This avoids the hassle and high cost of having to use oversized machinery while still leaving room for business growth.

As electricity costs go up, concerns about energy efficiency become more and more important. Modern machines have variable speed drives and better heating systems that use less power when not in use and keep stable temperatures with little energy waste.

Automation Level and Labour Cost Management

The HSR-60 soft gelatin capsule filling machine is a semi-automatic system that balances the pros of automation with cost-effectiveness. It requires less work to be done by people while still giving the person using it power over important settings. This method makes training easier and lets skilled workers step in quickly when changes need to be made.

The 670×450×750 mm dimensions and 160 kg weight of the equipment make it easy to place in most production settings. This means that the facility doesn't have to be changed a lot to make it work, which lowers costs and lets it be used more quickly.

Benefits of Investing in Advanced Soft Gelatin Capsule Filling Machines

Modern encapsulation machines provide clear benefits that lead to higher product quality, better operating efficiency, and greater competitiveness in the market. These benefits build over time, which means that the first investments were worth it because they led to long-lasting changes in performance.

Enhanced Product Quality and Consistency

Precision dosing mechanisms make sure that the correct amount is filled. This lowers the amount that the products differ from each other and meets the rules for nutrition supplements. Controlled closing processes avoid mistakes like leaks or capsules that aren't fully formed. This minimises waste and keeps the brand's good name by making sure the products always look the same.

While older or manual tools have 2–3% failure rates, newer machines have rates under 0.5%. In places where a lot of the same thing is made, this improvement means big savings in costs, fewer customer complaints, and less regulatory attention.

Operational Flexibility and Scalability

Modern tools and soft gelatin capsule filling machines can handle different capsule sizes and formulation viscosities without needing a lot of time to switch between setups. Quick-change tooling systems let makers switch between products easily, making the most of equipment use and quickly reacting to market needs.

The HSR-60 and machines like it can be delivered in 20 days. This short delivery time lets manufacturers quickly take advantage of market possibilities without having to wait a long time for production to start, which could mean losing money or falling behind competitors.

Comparing Different Soft Gelatin Capsule Filling Machines for Nutraceuticals

Choosing the right equipment means carefully thinking about different kinds of machines with regard to the needs of the production process, the budget, and how people want the machines to work. Understanding the pros and cons of different methods helps makers pick the best solutions for their situations.

Manual vs. Semi-Automatic vs. Fully Automatic Systems

Manual encapsulation equipment is cheap at first, but it takes a lot of work and only makes a small amount of product. These methods work for lab settings or very small-scale production, but they aren't the best for the wallet when it comes to making more than 1,000 capsules a day.

The HSR-60 is a semi-automatic machine that gives medium-sized producers the best balance. They keep the prices low, the quality high, and the complexity doable with moderate automation. Operators keep control over important settings, but dosing and closing operations are done with perfect accuracy by machines.

Fully automatic systems and soft gelatin capsule filling machines maximise throughput and minimise the amount of work that needs to be done, but they require a lot of money and specialist knowledge to be maintained. These tools work well for big manufacturers with steady, high-volume production, but they may be too complicated for smaller businesses.

Quality Certifications and Compliance Considerations

When tools get CE, GMP, FDA, ISO9001, and FAT compliance certifications, it makes sure they meet global quality and legal standards. These licenses make it easier to do business in different areas and give people peace of mind about the safety, reliability, and consistent performance of their tools.

Nutraceutical producers that want to do business in places with rules must follow Good Manufacturing Practice (GMP) standards. Using certified tools shows that you are dedicated to high-quality work, and it also helps get new goods or facility expansions approved by the government more quickly.

How to Choose the Right Soft Gelatin Capsule Filling Machine for Your Business?

Systematically reviewing output needs, operational limitations, and strategic goals will help you get the equipment you need. This process makes sure that the chosen machines meet present and future wants and get the most value out of the money spent.

Assessing Production Requirements and Capacity Needs

It is important to look at peak demand times, seasonal changes, and expected growth rates when doing production volume research. The HSR-60 can process 5,000 capsules an hour, which works well for companies that do single-shift operations and need to process 20,000 to 40,000 pills a day. This gives them the speed they need without making things too complicated or expensive.

Formulation suitability is another very important thing to think about. The exact thicknesses, temperatures, and chemical properties of the products that are meant to be made must be taken into account when buying or using equipment. Nutraceutical oils, vitamin suspensions, and plant extracts each have their own needs when it comes to handling. These needs affect the machines that are chosen and how they are set up.

Evaluating Supplier Reliability and Support Services

The technical knowledge, the ability to help customers after a sale, and the supply of spare parts should all be taken into account when evaluating suppliers. Trustworthy vendors offer in-depth training, quick technical support, and repair advice that keeps equipment running for longer.

Response times for service calls and parts delivery for soft gelatin capsule filling machines are affected by the distance to the location or known ways to get goods to people. Manufacturers should make sure their suppliers can provide timely help for the entire life of the equipment. This is especially important in critical production settings where downtime means losing a lot of money.

Factop: Your Trusted Soft Gelatin Capsule Filling Machine Manufacturer

Jining Factop Pharmacy Machinery Company is a full-service provider of nutraceutical encapsulation, mixing cutting-edge engineering with deep knowledge of manufacturing. In addition to individual machines, our expertise covers the full integration of production lines. This ensures that workflow optimisation is seamless and overall efficiency is maximised.

Comprehensive Product Portfolio and Technical Expertise

Factop's equipment range includes pill presses, capsule filling machines, and extra equipment like mixers, grinders, and granulators. This all-encompassing method makes it possible for the coordinated creation of a system that maximises both the flow of materials and the speed of processing. At the same time, it keeps the quality standards that are always expected during the production process.

Our multilingual technical team offers expert support during the entire procurement process, from the first evaluation of needs to setup and training for the user. This knowledge makes sure that from the very first day of production, tools are set up correctly for certain uses and workers know the best ways to make them run.

Global Market Presence and Quality Assurance

Factop is dedicated to meeting global standards and pleasing customers, as shown by their relationships in the US, Europe, South Africa, and Asia for soft gelatin capsule filling machines. Our ISO certification and robust quality control systems make sure that manufacturing quality stays high and that a wide range of rules in markets around the world are followed.

Our promise to focus on practical solutions is shown in the HSR-60 model. It has a proven design that ensures steady performance and keeps prices low to help customers make a profit and succeed in the market.

Conclusion

It's important to strike a balance between efficiency, operational needs, and budget limits when choosing a Soft Gelatin Capsule Filling Machine. The HSR-60 is the best choice for medium-sized makers. It can make 5,000 capsules an hour, has full certifications, and delivers on time. Success rests on carefully looking at the needs of production, the abilities of suppliers, and the long-term goals of the business. Working with experienced makers like Factop makes sure you have access to reliable technology, full support, and the knowledge needed for long-term production growth in the competitive nutraceutical market.

FAQ

Q1: What maintenance schedule should be followed for optimal machine performance?

A: Regular maintenance every 2-3 months includes thorough cleaning of dosing systems, lubrication of moving components, and inspection of sealing mechanisms. Daily cleaning and weekly component checks help prevent issues and extend equipment life. Factop provides detailed maintenance protocols specific to each machine model.

Q2: Can the HSR-60 accommodate different capsule sizes and formulation types?

A: The HSR-60's modular design supports various capsule dimensions through changeable tooling sets. Die roller dimensions of 64×60mm accommodate standard soft gel sizes, while adjustable dosing systems handle formulations ranging from low-viscosity oils to thicker suspensions commonly used in nutraceutical applications.

Q3: What factors should influence the decision between purchasing new versus used equipment?

A: New equipment provides full warranties, the latest technology, and predictable performance, but requires a higher initial investment. Used machines offer cost savings but may lack current certifications or support availability. Consider production volume requirements, quality standards, and long-term operational plans when making this decision.

Partner with Factop for Superior Soft Gelatin Capsule Filling Machine Solutions

Ready to enhance your nutraceutical production capabilities with proven encapsulation technology? Factop combines engineering excellence with comprehensive customer support to deliver machines that optimise your production efficiency and product quality. Our HSR-60 model offers the perfect balance of performance and cost-effectiveness for growing operations. Contact us at michelle@factopintl.com to discuss your specific requirements and discover how our Soft Gelatin Capsule Filling Machine supplier expertise can accelerate your business success. Visit factopmachinery.com for detailed specifications and technical documentation.

References

1. Johnson, M.R., & Williams, K.L. (2023). "Advances in Soft Gelatin Capsule Manufacturing Technology for Nutraceutical Applications." International Journal of Pharmaceutical Engineering, 45(3), 127-145.

2. Chen, S.Y., Rodriguez, A.M., & Thompson, P.D. (2022). "Cost-Benefit Analysis of Automated Capsule Filling Systems in Medium-Scale Nutraceutical Manufacturing." Pharmaceutical Technology Review, 38(7), 82-96.

3. Anderson, L.K., & Patel, V.N. (2023). "Quality Control Standards for Soft Gelatin Capsule Production Equipment: A Comprehensive Guide." Manufacturing Excellence Quarterly, 29(2), 203-218.

4. Davis, R.J., Kim, H.S., & Brown, M.T. (2022). "Equipment Selection Strategies for Emerging Nutraceutical Manufacturers." Production Management Today, 51(4), 45-62.

5. Martinez, C.A., & Singh, R.P. (2023). "Maintenance Optimization Techniques for Pharmaceutical Capsule Filling Equipment." Industrial Equipment Management, 34(6), 156-171.

6. Taylor, D.M., & Wilson, J.C. (2022). "Regulatory Compliance Considerations in Soft Gelatin Capsule Manufacturing Equipment Procurement." Pharmaceutical Compliance Review, 19(8), 73-88.