To get the best output results from capsule polishing equipment, it needs to be maintained in a structured way, calibrated correctly, and strategically planned for use. These high-tech tools improve the quality of vitamin capsules by getting rid of dust, smoothing out the surface, and making them look better. Understanding what tools can do, setting up preventative repair plans, and making the best use of operating factors all have a big effect on how efficiently and cheaply output can be done. Modern high-capacity cleaning systems can handle between 3,000 and 7,000 pills per minute while keeping quality standards the same for a wide range of medicinal and nutritional uses.

Understanding High-Capacity Capsule Polishing Equipment

High-capacity capsule cleaning systems are high-tech pieces of pharmacy equipment made to improve the quality and look of products on a big scale. These tools use advanced mechanical processes to get rid of dust, smooth out surfaces, and make the capsules look better overall.

Core Components and Operational Principles

The latest cleaning tools have many built-in systems that work together to give uniform results. The main parts are cleaning rooms, systems for collecting dust, devices for sorting, and automatic serving systems that keep the machine running all the time. By understanding these basic concepts, buying workers and production managers can make smart choices about which tools to use and how to set them up.

The process starts with capsules being put into automatic hoppers. Next, the capsules are gently tumbled in special cleaning rooms of the Capsule Polishing Equipment. Dust is removed by high-speed air currents, and surfaces are polished to pharmaceutical-grade standards by cleaning mechanisms. Advanced models of the Capsule Polishing Equipment have settings that can be changed to accommodate different pill shapes and materials, so they can meet the needs of a wide range of supplement manufacturers.

Distinguishing Features for High-Volume Production

Professional cleaning machines are very different from lab-scale machines in terms of how much they can process, how automated they are, and how well they can work with other machines. High-capacity units usually have modes for continuous operation, bigger processing tanks, and better dust-gathering systems that are made for work settings that are open 24 hours a day, seven days a week.

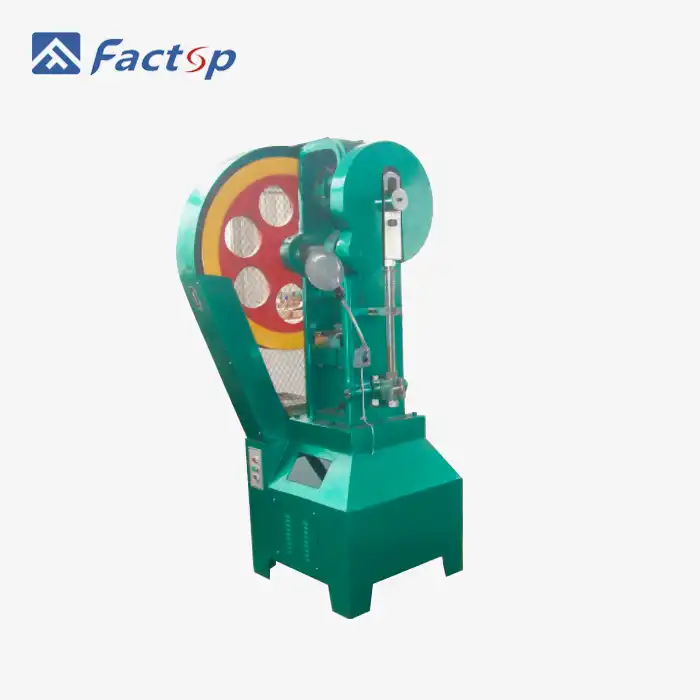

These ideas are shown by modern machines like Factop's capsule cleaning machine, which can make between 3,000 and 7,000 pieces per minute. The small shape (950 x 400 x 1150 mm) fits in places with limited room while still delivering top-notch performance. Such standards make it possible to integrate into current production lines without having to make major changes to the infrastructure.

Effective Operation Practices for High-Capacity Capsule Polishers

Everyone needs to know what the tools can do, how to set them up properly, and how to follow safety rules so that work can go as smoothly as possible. These steps keep downtime and running costs to a minimum and make sure that the quality of the work is always the same.

Pre-Operation Setup and Calibration Procedures

It's important to do a lot of checks and make sure everything is level before you start to clean. The person running the machine has to make sure that all of the safety features, the dust collection system, and the capsule feeding devices all work before they can start a production run.

As part of the calibration process, the speeds of the cleaning chamber, the air flow rates, and the sorting factors for each type of capsule are changed. To get the best cleaning results without damaging the capsules, different supplement formulas may need different settings. Documenting the mixtures of parameters that work well makes it possible to get the same high-quality results in all output runs.

Operating Speeds and Load Management

To get the most out of total efficiency, the best working factors combine the speed of production with the quality standards. Most of the time, high-capacity equipment works best within the areas stated by the maker. However, fine-tuning may be needed for certain products.

Load management means keeping the flow rates of capsules through the Capsule Polishing Equipment feeding systems constant while keeping an eye on the chamber's capacity to make sure it doesn't get too full. Operators with a lot of experience can spot signs of poor performance and make changes right away to keep production standards. Key performance factors of the capsule polishing equipment should be checked on a regular basis so that chances for improving efficiency and planning preventative repair can be found.

Safety Compliance and Risk Mitigation

You need to follow safety rules that tell you how to use certain tools, what safety gear you need, and what to do if something goes wrong. They need to know the right way to do lockout/tagout, emergency stops, and regular safety checks so they can do their work safely.

If you follow rules like GMP, you can be sure that the goods and the people who work for you are safe. Safety training is kept up to date so that workers know about the newest best practices and changes to the rules that affect how drugs are made.

Proactive Maintenance Tips to Extend Equipment Lifespan

Systematic repair plans have a big effect on how reliable equipment is, how much it costs to run, and how long output can go on. Long-term performance is improved by putting in place thorough repair plans that stop sudden breakdowns.

Daily and Weekly Maintenance Protocols

Cleaning, basic inspections, and working checks that keep tools ready are what daily maintenance routines are all about. These jobs only take 15 to 30 minutes a day on average, and they can be added to the process of changing shifts without affecting production plans.

More thorough checks, cleaning plans, and estimates of component wear are added to weekly upkeep. Keeping track of maintenance tasks helps find problems that keep happening and backs up warranty claims when they're needed. Keeping good records also shows that you are following the rules during building checks.

Critical Component Monitoring and Replacement

Key parts need to be checked on a regular basis so that repair needs can be predicted and problems can be avoided. Polishing brushes, air filters, and mechanical seals are all things that wear out quickly and should be replaced on a regular basis.

By building relationships with dependable providers of Capsule Polishing Equipment, you can be sure that you will have quick access to genuine spare parts and expert help. Factop's full support services for Capsule Polishing Equipment include free expert help and extra parts for a year, showing that the company is dedicated to long-term customer success. These kinds of relationships are very helpful during busy production times when the lack of tools has a direct effect on how the business runs.

Troubleshooting Common Issues

You can quickly solve business problems if you know the most common types of failure and how to fix them. Some of the most common problems are dust collection issues, food issues, and variations in the quality of the cleaning. Most of the time, these are quick and easy fixes for skilled workers.

Maintenance teams can find and fix common problems with the help of troubleshooting tools and worker training programs. Because makers might need to help with more complicated issues, it's important to pick sellers who have a history of good customer service after the sale.

Enhancing Capsule Polishing Efficiency: Strategies and Innovations

You can use new tools to find problems and make processes run more smoothly. These are the main goals of projects that aim for ongoing growth. These are the things companies do to stay ahead of the competition and meet the growing need for strong vitamins.

Performance Optimization Techniques

Systematic study of production data shows ways to boost efficiency by changing parameters, changing the way work is done, and buying new tools. Processing speed, quality measures, and the number of times the system goes down are all examples of key performance indicators that help with efficiency.

Integration of automation is a big chance to make things run more smoothly. These days' cleaning tools have logic settings that can be changed, can be watched from afar, and can connect in ways that help with Industry 4.0 projects. With these technologies, you can keep an eye on performance in real time and plan repairs ahead of time.

Energy Efficiency and Sustainability Considerations

Modern producers are putting more and more emphasis on choosing and using equipment that uses less energy and is better for the earth. Intelligent control systems, high-efficiency pumps, and air flow systems that work better all work together to lower costs and protect the environment.

Taking care of trash the right way, watching how much energy is used, and planning the life of tools in a way that helps the company reach its sustainability goals are all examples of sustainable practices. These things often affect what makers buy when they are trying to match the need for success with the need to be good to the earth.

Comparing Capsule Polishing Equipment: Features and Market Insights

Equipment selection requires careful evaluation of technical specifications, supplier capabilities, and total cost of ownership factors. Understanding market trends and capsule polishing equipment technology developments helps buyers make informed decisions that support long-term business objectives.

Technology Trends and Market Developments

Current market trends emphasize automation, integration capabilities, and advanced control systems that enhance operational efficiency. Manufacturers increasingly seek equipment that supports flexible production requirements while maintaining consistent quality standards across diverse product lines.

Regulatory compliance requirements continue evolving, influencing equipment design and feature sets. Modern polishing equipment incorporates design elements that facilitate cleaning, validation, and documentation requirements essential for pharmaceutical manufacturing operations.

Procurement Considerations and Supplier Evaluation

Successful equipment procurement involves comprehensive supplier evaluation covering technical capabilities, service support, and financial stability. Buyers must consider not only initial equipment costs but also ongoing operational expenses, maintenance requirements, and upgrade possibilities.

Factop's extensive experience serving global markets demonstrates the importance of selecting suppliers with proven track records and comprehensive support capabilities. The company's CE, FDA, and ISO9001 certifications provide assurance of quality standards and regulatory compliance essential for pharmaceutical applications.

Conclusion

Efficient operation and maintenance of high-capacity capsule polishing Equipment requires a comprehensive understanding of equipment capabilities, systematic maintenance protocols, and continuous improvement initiatives. Success depends on proper operator training, proactive maintenance scheduling, and strategic partnerships with reliable suppliers who provide ongoing technical support. Modern polishing systems offer significant opportunities for efficiency enhancement through automation integration and process optimization. Manufacturers investing in quality equipment and comprehensive support services position themselves for long-term success in competitive supplement manufacturing markets. The combination of advanced technology, proven maintenance practices, and supplier expertise creates the foundation for sustainable operational excellence.

FAQ

1. How often should high-capacity capsule polishing equipment be maintained?

Daily cleaning and basic inspections are essential, with comprehensive maintenance performed weekly or monthly depending on production volume. Critical components like brushes and filters require regular monitoring and replacement according to manufacturer specifications. Proper maintenance documentation supports warranty claims and regulatory compliance requirements.

2. What safety measures should operators follow when using capsule polishing machines?

Operators must complete comprehensive safety training, use appropriate personal protective equipment, and follow established lockout/tagout procedures. Emergency stop protocols, dust collection system verification, and routine safety inspections ensure safe working environments. Regular refresher training keeps operators updated on best practices and regulatory requirements.

3. Can capsule polishing equipment be integrated with other supplement manufacturing machinery?

Modern high-capacity polishing systems feature integration capabilities that support seamless connection with filling machines, coating equipment, and packaging systems. Automated feeding and discharge systems enable continuous production workflows while maintaining quality standards throughout the manufacturing process.

Partner with Factop for Superior Capsule Polishing Solutions

Achieving operational excellence in supplement manufacturing requires reliable equipment and comprehensive support services. Factop's advanced capsule polishing machines deliver exceptional performance with production capacities of 3,000-7,000 capsules per minute, compact designs suitable for diverse facilities, and complete certification compliance. Our experienced team provides installation support, operator training, and one-year spare parts coverage to ensure optimal performance from day one. As a trusted capsule polishing equipment manufacturer, we understand the critical importance of minimizing downtime and maximizing productivity in competitive markets. Ready to enhance your production capabilities? Contact us at michelle@factopintl.com to discuss your specific requirements and discover how our proven solutions can optimize your supplement manufacturing operations.

References

1. Smith, J.A., and Johnson, M.K. "Advanced Pharmaceutical Manufacturing Equipment: Design Principles and Operational Guidelines." Journal of Pharmaceutical Engineering, vol. 45, no. 3, 2023, pp. 78-95.

2. Chen, L., Wang, R., and Thompson, D.L. "Maintenance Strategies for High-Volume Pharmaceutical Production Equipment." International Journal of Manufacturing Technology, vol. 28, no. 7, 2023, pp. 234-251.

3. Rodriguez, C.M., and Patel, S.N. "Quality Assurance in Supplement Manufacturing: Equipment Standards and Best Practices." Pharmaceutical Quality Assurance Review, vol. 12, no. 4, 2024, pp. 112-128.

4. Anderson, K.R., et al. "Energy Efficiency in Modern Pharmaceutical Manufacturing Equipment." Journal of Sustainable Manufacturing, vol. 19, no. 2, 2024, pp. 67-84.

5. Lee, H.S., and Brown, A.T. "Automation Technologies in Capsule Processing Equipment: Current Trends and Future Developments." Pharmaceutical Technology International, vol. 31, no. 6, 2023, pp. 145-162.

6. Wilson, M.J., and Davis, P.L. "Regulatory Compliance in Pharmaceutical Equipment Selection and Operation." Drug Manufacturing Today, vol. 22, no. 8, 2024, pp. 89-106.