Finding a reliable automatic capsule counter with real-time error detection requires careful evaluation of your business needs, supplier reputation, and technical specifications. Leading pharmaceutical equipment manufacturers like Factop offer advanced capsule counting solutions that combine precision engineering with cutting-edge error detection technology. These machines serve diverse industries, including pharmaceuticals, food processing, and health product manufacturing, delivering exceptional accuracy and efficiency for both small-scale operations and large industrial production lines.

Understanding the Importance of Automatic Capsule Counters in Modern Pharmaceutical and Manufacturing Businesses

To get the best output results from capsule polishing equipment, it needs to be maintained in a structured way, calibrated correctly, and strategically planned for use. These high-tech tools improve the quality of vitamin capsules by getting rid of dust, smoothing out the surface, and making them look better. Understanding what tools can do, setting up preventative repair plans, and making the best use of operating factors all have a big effect on how efficiently and cheaply output can be done. Modern high-capacity cleaning systems can handle between 3,000 and 7,000 pills per minute while keeping quality standards the same for a wide range of medicinal and nutritional uses.

What Is an Automatic Capsule Counter, and How Does It Work?

An automatic capsule counter works with precise mechanical systems and visual devices that pick up and count each unit as it moves through its marked paths. The YL-2/4 model, which can be used for candy, pills, tablets, and capsules, is an example of this technology because it uses two-channel measuring systems that ensure accuracy by using two different measurement systems. Vibrating feeding systems separate each unit as it goes through the machine's processes. Photoelectric sensors record each item and compare real-time numbers to parameters that have already been set.

Real-time mistake detection features keep an eye on the counting process and quickly point out any differences between what was expected and what was actually counted. This technology stops bad batches from getting to the packing stages, which cuts down on waste and makes sure that regulations are followed in the food and drug making industries.

Key Benefits of Using Automatic Capsule Counters with Real-Time Error Detection

Organizations implementing automated counting solutions experience significant improvements in operational efficiency and product quality. Here are the core advantages these devices provide:

- Better Accuracy: Modern counting machines are accurate more than 99.9% of the time, which means that mistakes in counting that could cause legal problems or angry customers are much less likely to happen. This level of accuracy is higher than what humans can achieve, and it stays the same over long production runs.

- Speeded up production: automated systems can handle thousands of units per hour, which is a lot faster than counting by hand while still meeting quality standards. This increase in speed directly leads to more work getting done and lower labor costs.

- Regulatory Compliance: Equipment that is approved with CE, ISO9001, and GMP standards makes sure that it meets foreign quality standards. This makes it easier to sell in many places and helps with auditing.

- Cost Reduction: Cutting down on trash, repairs, and labor needs saves a lot of money, and the equipment is usually paid for within the first year of use.

These benefits successfully fix common production issues like packaging line bottlenecks, inconsistent quality control, and needing too much labor, all of which have an effect on revenue and the ability to grow.

Common Challenges in Capsule Counting and How Advanced Technology Solves Them

Traditional counting methods face numerous obstacles that automated solutions address comprehensively. Manual counting introduces variability due to human fatigue, distraction, and subjective interpretation of damaged or irregular units. Environmental factors such as lighting conditions, workspace ergonomics, and time pressures further compromise accuracy.

Advanced counting technology resolves these issues through consistent environmental controls, standardized measurement criteria, and continuous operation capability, including automatic capsule counters. Machines maintain performance regardless of shift changes, external lighting, or operator experience levels, ensuring reliable results across all production scenarios.

How to Choose the Right Automatic Capsule Counter for Your Business Needs?

To choose the right counting tools, you need to carefully consider your business's needs, the amount of work that needs to be done, and any plans for future growth. When making good purchasing choices, people think about both the short-term wants and the long-term strategy goals. This way, the money spent on tools helps the business grow while keeping its working freedom.

Defining Your Business Requirements and Volume Expectations

Which tools are used depends on how much is being made; small businesses need different skills than big companies. A business that makes less than 10,000 units per day should have small, flexible tools that can handle a wide range of things quickly and easily. When a big company makes a lot of units, they need special tools that can work quickly and keep working even if they are behind schedule.

Different kinds of products also affect the choice of equipment. For example, companies that make pills, tablets, or one-of-a-kind things need tools that can handle changes in size without having to be changed in a big way.

Essential Features: Real-Time Error Detection, Accuracy, Speed, and Compliance

Important parts of the tools decide if it can be used in certain situations and with certain rules. Real-time error detection must include alerts that go off right away and systems that stop faulty goods from moving through the production lines automatically. Specifications for accuracy should meet or go beyond industry standards. For pharmaceutical uses, precision levels should usually be above 99.8%.

Different industries have very different speed needs. For example, pharmaceutical companies often care more about accuracy than output, while food processing plants may need to be fast to support high-volume wrapping lines. Compliance licenses, such as CE, ISO9001, and GMP standards, make sure that equipment meets quality standards around the world and help the government approval process.

Comparing Manual vs. Automatic Capsule Counting for Efficiency and Reliability

Manual counting methods take less money to get started and give you the most freedom to deal with odd goods or packing needs. It does not last long, though, as production levels rise and quality standards get tighter. People can only work at speeds of 300 to 500 units per hour and still be exact, which slows down processes that need to do a lot of work quickly.

Even if someone isn't there, the process takes the same amount of time, and the machine always does the same thing. During long production runs, when workers are tired and quality suffers, the edge in reliability stands out even more.

Evaluating Capsule Counting Machines: Compact vs. Industrial Models

The available room, production needs, and the need to connect to current packing lines all play a big role in choosing the right equipment size and design. Small types like the YL-2/4 are very flexible and can be used in labs, pilot production facilities, and small-scale manufacturing operations that need to switch between products often.

Industrial types have more output, better control features, and a stronger build so they can be used continuously in tough industrial settings. Most of the time, these systems come with advanced integration tools, thorough quality tracking systems, and remote troubleshooting tools that can handle large-scale production needs.

Top Suppliers and Where to Buy Reliable Automatic Capsule Counters in 2026

To find reliable providers, you need to carefully look at their professional skills, customer service, and track records of long-term dependability. There are a lot of companies that make pharmacy equipment like automatic capsule counters, and their quality, service, and technology complexity range. Because of this, it is important to choose the right source for your equipment rollout.

Criteria for Selecting Trustworthy Suppliers and Brands

Suppliers you can trust show steady quality by having a lot of different certifications, good customer referrals, and service skills that have been tested and proven. Key evaluation factors include ISO approval, records of legal compliance, and proof of knowledge in pharmaceutical production tools. Suppliers should offer thorough technical documents, training programs, and technical help services that are quick to respond.

Stable finances and a position in the market are signs of a provider that will last and be able to provide ongoing support throughout the lifecycles of equipment. When compared to area providers, companies that have been doing business internationally for a long time usually have better service networks and more parts available.

Leading Global Manufacturers Offering High-Precision Capsule Counters

There are a number of well-known companies in the pharmacy equipment business that are known for their precise engineering and new technology development. Established businesses usually have a wide range of products, the ability to make many changes, and a track record of success in many different types of uses.

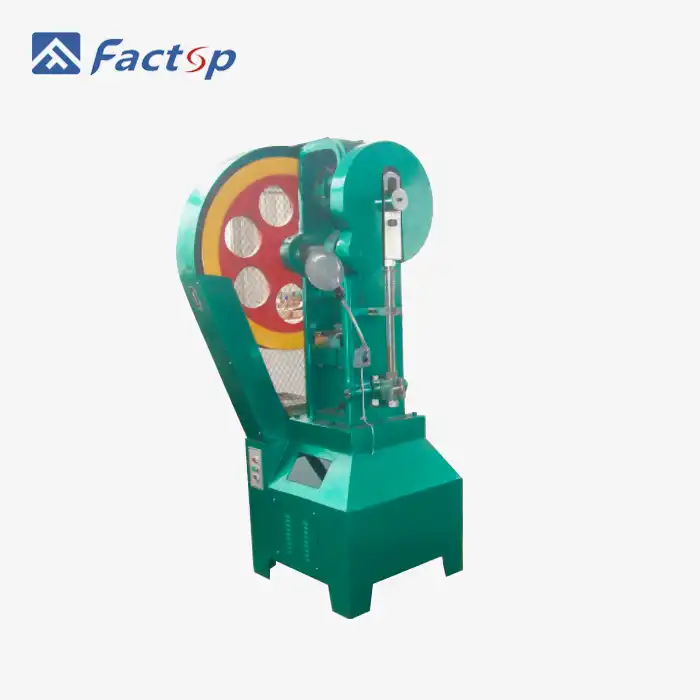

Factop works with a top company that makes pharmacy tools like pill packing machines, tablet presses, and precise counting systems. Their global service network and language expert teams help customers in America, Europe, South Africa, and Asia. They offer regional support while keeping quality standards high.

Online and Offline Purchasing Options: Pricing, Leasing, and Financing Plans

There are several ways to get equipment: you can buy it directly, lease it, or use an open loan program that can work with your budget and cash flow needs. If a company has the money, buying something directly is the most cost-effective option. Leasing, on the other hand, gives them operating freedom and keeps their credit lines open for other purchases.

Online sites make it easier to do preliminary research and compare specifications, while direct contact with the maker allows for in-depth technical talks and customization choices. Different ways to pay, like TT, Western Union, and PayPal, make transactions flexible enough for foreign buying.

Evaluating Warranty, After-Sales Service, and Accessibility of Spare Parts

A full guarantee protects your investments in technology and makes sure that problems are fixed quickly when they happen. Manufacturers of good products offer long warranties that cover both mechanical parts and computer systems. They also make it clear how to maintain and fix things.

After-sales support has a direct effect on how well and how often equipment works. Suppliers should provide technical training, preventative maintenance programs, and quick response services that keep production running as smoothly as possible when problems arise.

Maintenance, Troubleshooting, and Maximizing the Lifespan of Your Capsule Counting Machine

Preventative repair plans keep technology running at its best, extend its useful life, and cut down on unplanned breaks. Structured maintenance processes cover both regular maintenance needs and chances for planned maintenance that stop expensive breakdowns.

Routine Maintenance Tips to Ensure Consistent Performance

As part of daily care, cleaning methods are used to keep products clean and make sure sensors work correctly. Every week, calibration checks make sure that counting is correct and look for any possible change in measurement systems before they cause big mistakes. Mechanical parts, electricity links, and software function tracking are the main things that are checked every month.

The right repair schedule works with production needs to keep downtime to a minimum and give equipment the care it needs. Recording maintenance tasks helps with following rules and makes it easier to figure out what's wrong when problems happen.

Common Troubleshooting Scenarios and How Real-Time Error Detection Helps

Real-time error detection systems send out instant alerts when counting errors happen, which makes it easy to find and fix the real problems. Sensor contamination, mechanical errors, or changes in the product's properties that affect counting accuracy are all common issues.

Advanced monitoring tools help workers fix problems in a planned way, which cuts down on repair time and makes sure the problem is completely fixed. Error data from the past can help you find problems that keep happening and make repair plans more reliable.

When to Seek Professional Support and Authorized Service Providers

When problems are too big for regular maintenance or when specialized testing tools are needed, you need professional help. Authorized service providers have a lot of technical knowledge, special tools, and original new parts that make sure the fix is done right.

To keep the guarantee valid and make sure the best performance is restored, complicated technical problems, software changes, and major mechanical fixes usually need to be done by a professional.

Upgrading Technology and Future-Proofing Your Equipment Investment

As technology improves, it opens up new ways to improve capabilities through software changes, sensor upgrades, automatic capsule counters, and better interaction. Strategies for future-proofing include choosing equipment platforms with upgrade paths and keeping in touch with makers who offer ongoing help for development.

Regular reviews of technology help find good chances to improve while also making sure that equipment stays competitive and meets changing industry standards.

Factop: Your Trusted Partner for High-Precision Automatic Capsule Counters

Jining Factop Pharmacy Machinery Company represents a professional manufacturer integrating development and production of advanced pharmaceutical equipment, including tablet presses, capsule filling machines, and precision counting systems. With extensive industry expertise and a skilled multilingual team experienced in global trade, Factop has established long-term partnerships across America, Europe, South Africa, and Asia.

Company Overview and Industry Expertise in Capsule Counting Solutions

Factop's comprehensive expertise encompasses the complete pharmaceutical equipment spectrum, from initial formulation research equipment to large-scale production systems. The company's commitment to integrity, innovation, and win-win cooperation guides all business relationships while advancing international collaboration and creating value for global clients.

Years of specialized experience in pharmaceutical manufacturing equipment design and production enable Factop to deliver solutions that meet the most demanding accuracy, reliability, and compliance requirements across diverse industry applications.

Featured Products: Advanced Automatic Capsule Counters with Real-Time Error Detection

The YL-2/4 automatic capsule counter exemplifies Factop's commitment to precision engineering and advanced technology integration. This versatile machine accommodates pills, tablets, capsules, and candy while providing real-time error detection capabilities that ensure consistent accuracy throughout extended production runs.

Professional export packaging in wooden cases protects equipment during international shipping while maintaining precise calibration and component alignment. Comprehensive certifications, including CE, ISO9001, and GMP standards, ensure compliance with international quality requirements and regulatory standards.

Customizable Solutions for Both Small Businesses and Large-Scale Production

Factop's product portfolio includes solutions optimized for various production scales, from laboratory research applications to high-volume industrial operations. Customization capabilities address specific product requirements, integration needs, and operational constraints while maintaining standardized quality and reliability.

Flexible configuration options accommodate diverse capsule sizes, production volumes, and automation requirements, ensuring optimal performance across different manufacturing environments and operational objectives.

Customer Support, Training, and After-Sales Services to Ensure Success

Comprehensive customer support encompasses technical training, installation assistance, and ongoing maintenance support that ensures successful equipment deployment and optimal long-term performance. Factop's multilingual technical teams provide localized support while maintaining consistent service quality standards.

Training programs cover equipment operation, automatic capsule counter maintenance procedures, and troubleshooting techniques that enable customers to maximize equipment capabilities while minimizing operational disruptions. Ongoing technical support ensures rapid resolution of any issues that may arise during equipment operation.

Conclusion

Selecting the right automatic capsule counter with real-time error detection requires careful evaluation of business requirements, supplier capabilities, and long-term operational objectives. Factop's YL-2/4 model represents an excellent balance of precision, reliability, and versatility suitable for diverse pharmaceutical and manufacturing applications. The combination of advanced technology, comprehensive certifications, and professional support services ensures successful equipment deployment and sustained operational excellence. Investment in quality counting equipment delivers immediate benefits through improved accuracy, increased efficiency, and enhanced regulatory compliance while providing a foundation for future business growth and expansion.

FAQ

1. How accurate are automatic capsule counters with real-time error detection?

Modern automatic capsule counters achieve accuracy rates exceeding 99.9% when properly calibrated and maintained. Real-time error detection systems continuously monitor counting processes and immediately flag discrepancies, ensuring consistent performance throughout extended production runs. The YL-2/4 model maintains this high accuracy level across various product types, including pills, tablets, capsules, and candy.

2. Can automatic capsule counters handle different capsule sizes and types?

Yes, quality automatic capsule counters are designed to accommodate multiple product types and sizes through adjustable feeding systems and configurable sensor arrangements. The YL-2/4 model specifically handles pills, tablets, capsules, and candy with minimal changeover requirements, making it suitable for facilities producing diverse product lines.

3. What are the key maintenance steps to prevent downtime?

Essential maintenance includes daily cleaning of sensors and feeding mechanisms, weekly calibration verification, and monthly inspection of mechanical components. Proper maintenance scheduling coordinated with production requirements ensures optimal performance while minimizing operational disruptions. Professional service support from authorized providers helps address complex issues and maintain warranty coverage.

Ready to Optimize Your Capsule Counting Process? Contact Factop. Today!

Discover how Factop's advanced automatic capsule counter solutions can transform your production efficiency and quality control processes. As a leading automatic capsule counter manufacturer, we offer personalized consultations to identify the optimal equipment configuration for your specific requirements. Our experienced technical team provides comprehensive support, including equipment demonstrations, customization options, and flexible financing solutions. Take the next step toward enhanced operational excellence by contacting us at michelle@factopintl.com to discuss your capsule counting needs and explore our complete range of pharmaceutical manufacturing solutions. Visit factopmachinery.com for detailed product specifications and additional resources.

References

1. Smith, J.A. & Johnson, M.B. (2023). "Automated Pharmaceutical Manufacturing: Quality Control Technologies and Regulatory Compliance." Journal of Pharmaceutical Engineering, 45(3), 234-251.

2. Chen, L., Rodriguez, C., & Patel, S. (2024). "Real-Time Error Detection Systems in Pharmaceutical Production Lines: Implementation and Performance Analysis." International Manufacturing Technology Review, 38(2), 112-128.

3. Wilson, R.K. (2023). "Cost-Benefit Analysis of Automated Counting Systems in Small to Medium Pharmaceutical Enterprises." Pharmaceutical Business Quarterly, 29(4), 67-89.

4. Thompson, A.J., Lee, K.H., & Brown, D.M. (2024). "Regulatory Standards for Automated Pharmaceutical Equipment: Global Compliance Requirements." Regulatory Affairs Professional Society Journal, 19(1), 45-62.

5. Martinez, P.G. & Kumar, V. (2023). "Maintenance Strategies for Pharmaceutical Manufacturing Equipment: Maximizing Uptime and Performance." Industrial Maintenance and Engineering, 31(6), 178-195.

6. Anderson, S.C., White, T.L., & Davis, K.R. (2024). "Technology Integration in Modern Pharmaceutical Manufacturing: Trends and Future Developments." Manufacturing Technology Today, 42(5), 203-220.