pharmaceutical tablet presses

Model: ZP420-27/29/31D

Production capacity: 81000/93000/104400pcs/hour

Max pressure: 100KN

Max tablet diameter: 20-30mm

Max tablet thickness: 1-7mm/6-12mm

High-Speed Rotary Tablet Machine: Professional Pharmaceutical Tablet Presses for Modern Manufacturing

Looking for reliable pharmaceutical tablet presses to boost your production efficiency? The ZP420 line of our high-speed rotary tablet machines works very well in pharmaceutical factories, health product factories, and hospital preparation rooms. These high-tech products mix cutting-edge technology with easy-to-use controls to make sure that the quality of your tablets stays uniform while you increase your production output. Our tools give your business the accuracy and dependability it needs whether you're making medicines, dietary supplements, or health goods.

Main Parameter

| Feature | Details |

|---|---|

| Model | ZP420-31D pharmaceutical tablet presses |

| Production Capacity | 111600pcs/hour |

| Speed | 5-30rpm |

| Tablet press diameter | Max 20mm |

| Tablet thickness range | 2-8mm |

| Motor Power | 11kw |

| Dimensions (LxWxH) | 1410*1100*2100 |

| Weight | 1950kg |

Advanced Technology for Superior Performance

Three powerful types in our ZP420 line are available to meet a range of production needs. At 93,000 pieces per hour, the ZP420-29D beats the ZP420-27D's output of 81,000 pieces per hour. At its highest setting, the ZP420-31D can produce an amazing 104,400 pills per hour.

Each machine can handle up to 100KN of pressure, which makes sure that all production runs of tablets are compressed the same way. You can make tablets with a width of 20 to 30 mm and a thickness of 1 to 7 mm or 6 to 12 mm, based on what you need.

When compared to standard single-punch machines, the rotary form cuts production time by a large amount. Your workers will like the easy-to-use controls and automatic features that keep exact tablet specs while reducing the need for manual work.

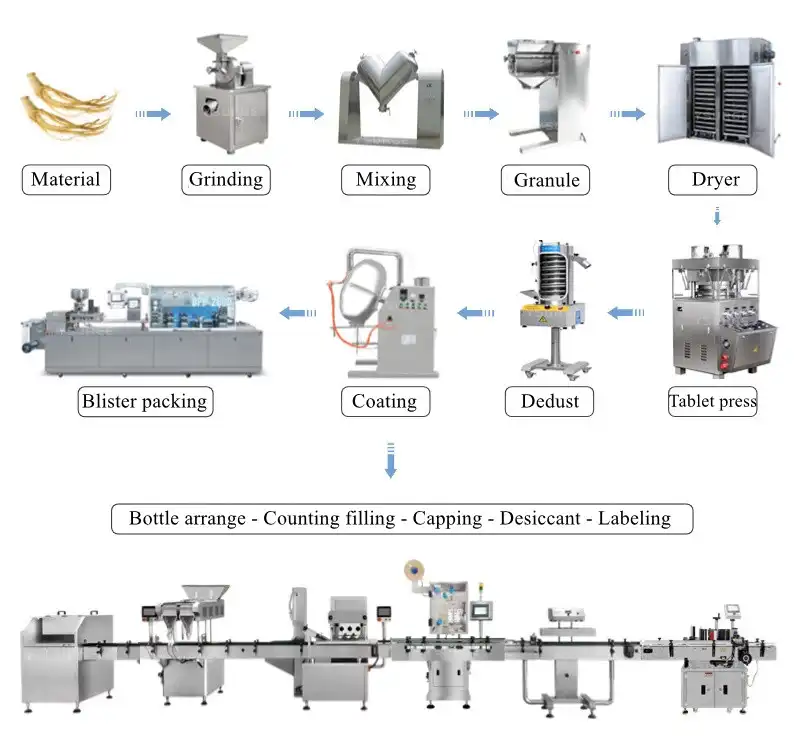

Production Process

GMP-Certified Quality You Can Trust

Compliance is the first step toward quality. Every equipment in our production plant satisfies worldwide pharmaceutical requirements thanks to its GMP accreditation. You may feel secure knowing that your product will withstand regulatory inspections and uphold constant quality requirements thanks to this certification.

Before shipping, we carry out thorough Factory Acceptance Testing, or FAT. Before your equipment leaves our facilities, this thorough testing procedure ensures that it operates as intended. You get thorough test documentation to help you with your validation procedures.

Our wooden box export packaging protects your investment during international shipping. This specialized packaging prevents damage and ensures your machine arrives in perfect condition, ready for installation.

Quality Control

Comprehensive Support and Service

It is important for your company to have your manufacturing line up and running as soon as possible. We offer on-site commissioning and installation assistance to guarantee a seamless starting. Together with your team, our skilled experts educate your operators and maximize equipment performance.

Every pharmaceutical tablet presses purchase includes free spare parts for the first year. This coverage protects your investment and minimizes unexpected maintenance costs during the critical startup period.

Our multilingual technical team understands international trade procedures and can communicate effectively in your preferred language. This expertise ensures clear communication throughout the purchasing and installation process.

Packaging, Transportation and Workshop

Versatile Applications Across Industries

These machines serve multiple industries beyond traditional pharmaceuticals. Food factories use them for creating compressed nutritional supplements and functional foods. Chemical plants rely on our equipment for industrial tablet production.

The accuracy and reliability our machines provide for dietary supplements and nutraceuticals are valued by health product makers. The small-batch pharmaceutical compounding's dependable operation and compact design are advantageous for hospital preparation rooms.

Different tablet formulations, such as immediate-release, sustained-release, and specially coated tablets, are supported by the adaptable architecture. There is little downtime when your manufacturing crew switches between goods.

Application Areas

Fast Delivery and Global Reach

We are aware that in the pharmaceutical production process, time equals money. Our efficient production method guarantees prompt delivery without sacrificing quality. In order to speed shipment to your area, we maintain excellent partnerships with logistical partners throughout the world.

America, Europe, South Africa, Korea, the Philippines, and Indonesia are among our international clientele. Because of our global experience, we are able to modify our solutions to satisfy local standards and comprehend a variety of regulatory needs.

Customer Support

Exhibitions

Contact Us

Ready to enhance your tablet production capabilities? Contact our team at michelle@factopintl.com to discuss your specific requirements. We'll help you select the ideal pharmaceutical tablet presses configuration for your production goals and provide detailed technical specifications and pricing information.

YOU MAY LIKE