Vice tablet press

Feature: With forced feeder

Punch dies: 5/7/9 punches

Max press diameter: 20mm

Max thickness: 6mm

Production capacity: 9000/13000/16200 pcs/hour

Vice Tablet Press: Professional Pharmaceutical Manufacturing Solution

Are you looking for a reliable Vice tablet press to boost your pharmaceutical production? You're in the right place. Our high-tech tablet compression tools consistently produce good results for study centers, health product makers, and pharmaceutical companies all over the world. The product is great for small to medium-sized business needs because it is both well-designed and easy to use.

Product Specifications

| Specification | Details |

|---|---|

| Model | Vice Tablet Press |

| Max Output | 16200 tablets/hour |

| Tablet Diameter | 5 mm - 20 mm |

| Max Pressure | 60 KN |

| Motor Power | 2.2kw |

| Weight | 220 kg |

| Dimensions | 650*500*1100mm |

| Certification | ISO 9001:2015, CE |

Why Choose Our Tablet Compression Equipment?

Versatile Production Capabilities

Our ZP series offers three configurations to match your production requirements. The ZP5 model produces 9,000 tablets per hour with 5 punches. The ZP7 variant increases output to 13,000 pieces hourly using 7 punches. For higher volume needs, the ZP9C delivers 16,200 tablets per hour with 9 punch stations.

Before being sent out, every machine goes through FAT (Factory Acceptance Testing). This thorough test shows that all features work as expected. You get full test papers along with your gear.

Advanced Forced Feeder System

The integrated forced feeder ensures consistent powder flow into the die cavities. This technology eliminates common issues like weight variation and incomplete filling. Your tablets will have uniform density and accurate dosing every time.

The forced feeding works great with powders that are hard to move. Materials that are hard to work with in the past are now easier to handle with this method.

GMP-Certified Quality Standards

Good Manufacturing Practice rules are followed in our factory. Before it is sent out, every machine goes through a lot of quality checks. When you buy something, you get paperwork for Factory Acceptance Testing.

The wooden box export packaging protects your investment during international shipping. We've successfully delivered equipment to customers across America, Europe, South Africa, Korea, Philippines, and Indonesia.

Comprehensive Support Package

With your buy, you get free covering for spare parts for a year. Our skilled expert team can help with installation and start-up at your location. This hands-on help makes sure that the system starts up smoothly and works at its best right away.

We also offer ongoing technical consultation throughout your machine's lifecycle. Our multilingual team understands international trade requirements and can assist with documentation and compliance needs.

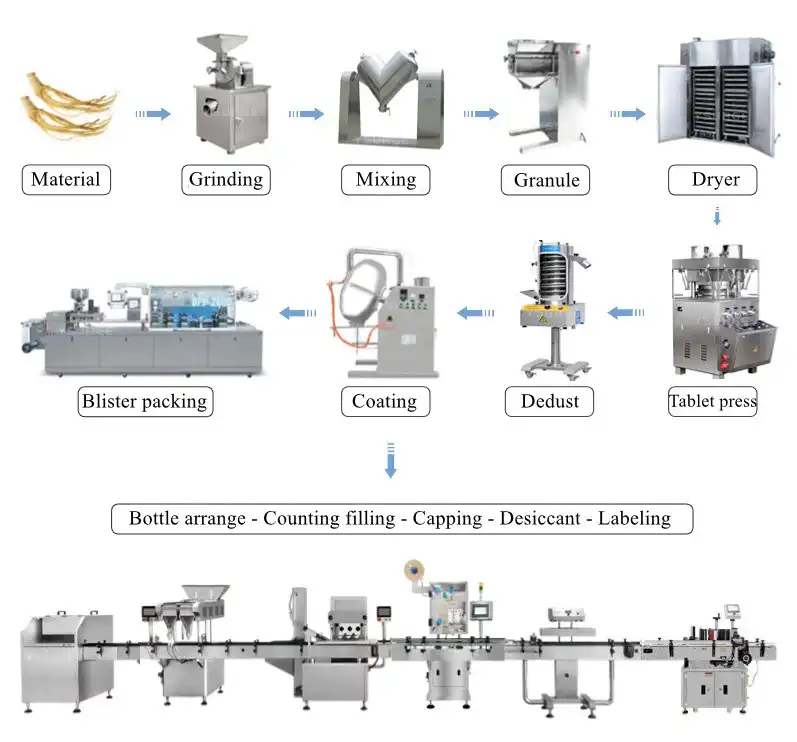

Production Process

Perfect Applications

Pharmaceutical Manufacturing

Hospital preparation rooms benefit from the compact design and precise control features of the Vice tablet press. The equipment handles both research batches and regular production runs efficiently.

Pharmaceutical factories use our machines for contract manufacturing and specialized formulations. The easy changeover between different products maximizes production flexibility.

Health Product Industry

Dietary supplement makers like how the tablets always work and how well they are made. The machine works with different mixtures, such as vitamins, minerals, and plant products.

Food supplement producers find the GMP certification valuable for regulatory compliance. The hygienic design meets strict cleanliness requirements for food-grade applications.

Chemical Applications

Chemical plants use the equipment for specialty tablets and compressed products. The robust construction handles challenging materials while maintaining precision.

Application Areas

Technical Excellence

Standard tools setups can be used with the punch and die system. With quick switching, there is less downtime between runs of a product. For different formulas, it's easy for operators to change the compression force and tablet width.

The control system provides intuitive operation with clear monitoring of all critical parameters. Production data logging helps maintain quality records and process documentation.

Global Partnership Network

Factop International Trade Company has built strong relationships with customers worldwide. Our business philosophy emphasizes integrity, innovation, cooperation, and mutual success. We're committed to creating greater value for every customer.

Our experienced team combines technical expertise with market knowledge. We understand the challenges facing pharmaceutical manufacturers and provide solutions that drive business growth.

Packaging and Transportation

Contact Us

Ready to enhance your tablet production capabilities? Contact us at michelle@factopintl.com to discuss how our Vice tablet press can meet your specific manufacturing requirements and boost your operational efficiency.