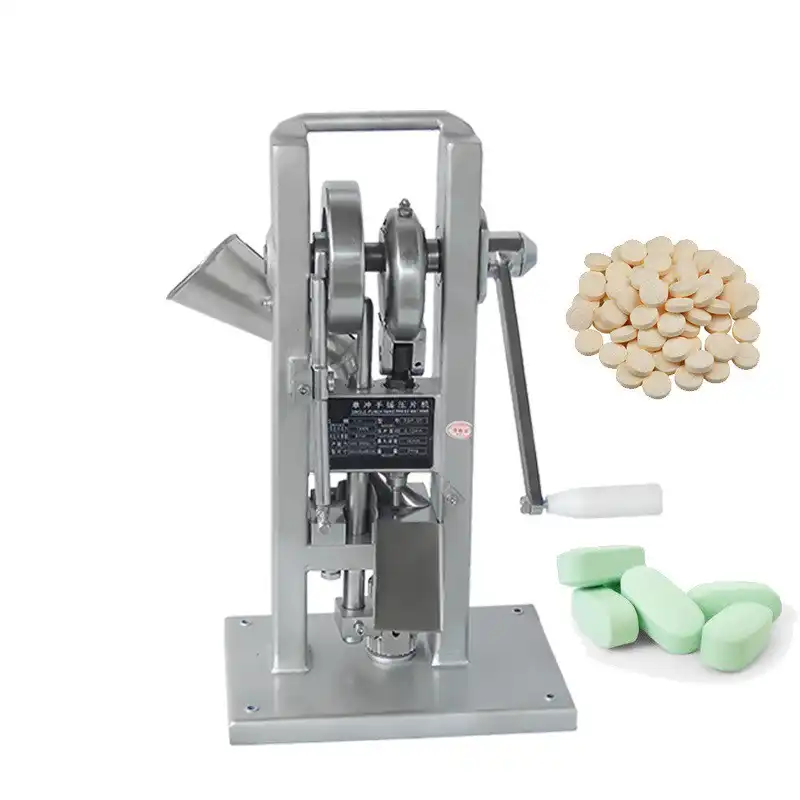

Single-station tablet making machine

Max pressure: 50KN

Max press diameter: 25mm

Max filling depth: 20mm

Max tablet thickness: 8mm

Voltage: 110/220V, 1.5kw

Single-Station Tablet Making Machine - Precision Manufacturing Solution

Are you looking for a reliable and efficient tablet production solution? Our Single-station tablet making machine delivers exceptional performance for small to medium-scale pharmaceutical manufacturing. With its precise engineering, this small machine strikes the right mix between quality, efficiency, and price. Our tablet press gives you reliable results every time, whether you run a drug plant, a health product facility, or a hospital preparation room.

Main Parameter

| Feature | Description |

|---|---|

| Model | DP50 Single Station Tablet Press |

| Maximum Tablet Pressure | 50 kN |

| Max Tablet Diameter | 25 mm |

| Max Tablet Thickness | 8 mm |

| Output Capacity | 3600 Tablets per hour |

| Motor Power | 1.5 kW |

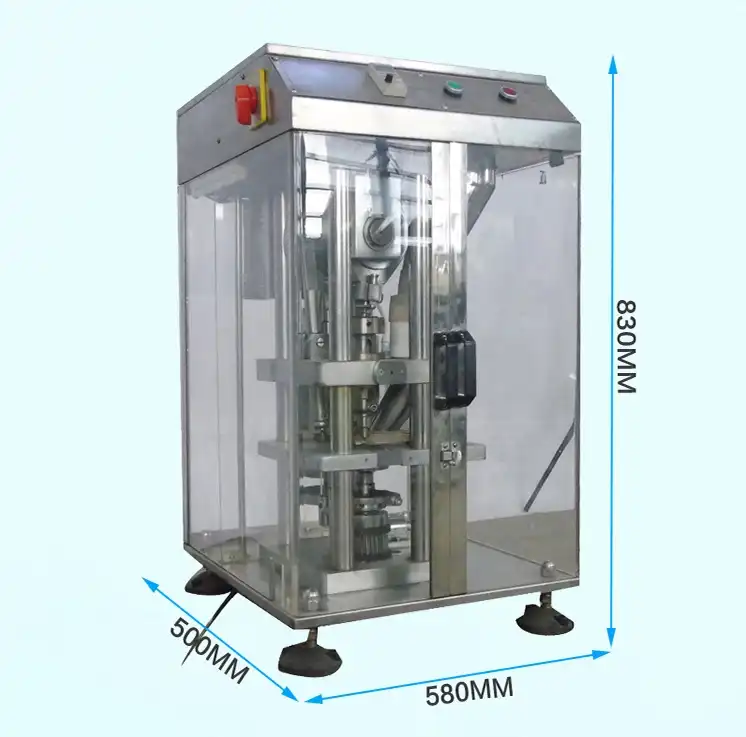

| Dimensions | 580*500*830 mm |

| Weight | 250 kg |

| Material | Stainless Steel 304 |

Advanced Features That Set Us Apart

The tools we use to make tablets are full of cutting-edge features. The DP50 type has great features that make it suitable for a wide range of output needs. With a maximum pressure of 50KN, you can make pills that are very strong and last a long time.

Up to 25 mm in width, the machine can handle tablets. Your ability to change these features lets you make tablets of different sizes for different uses. The highest filling depth is 20 mm, which gives you options for how to make dosages.

You'll appreciate the precise tablet thickness control up to 8mm. This ensures uniform product quality across every batch. The dual voltage capability (110V/220V) with 1.5kw power consumption makes installation easy in any facility.

Why Choose Factop for Your Production Needs?

Factop brings decades of experience making medicinal machines. We know that making tablets comes with its own set of problems. Our skilled team blends expert know-how with useful manufacturing solutions.

Our buildings are GMP-certified to make sure that every machine meets the highest quality standards around the world. With this license, you can be sure that the rules will be followed. Tests and quality checks make sure that your investment is safe.

Quality Control

Our product undergoes rigorous FAT (Factory Acceptance Testing). Each unit receives thorough inspection before shipment. We provide detailed certification documentation for your records.

Comprehensive Support and Service

Installation doesn't have to be stressful. We offer on-site installation and commissioning support to get your operation running smoothly. Our technical experts guide you through every step of the setup process.

Every buy comes with training. Your workers will learn how to properly run the machines, do upkeep, and fix problems. This sharing of knowledge guarantees top success from the start.

Fast delivery keeps your project timeline on track. We understand production schedules are critical. Our efficient logistics network ensures timely equipment arrival.

Quality Assurance and Reliability

Every machine receives professional wooden box export packaging. This protection ensures your equipment arrives in perfect condition. We take extra care in securing all components during transport.

For one whole year after the buy, extra parts are given away for free. This insurance saves your investment and keeps downtime to a minimum. Items of everyday wear are easy to find when you need them.

Our proven technical team stands behind every Single-station tablet making machine. Years of field experience inform our design improvements. Customer feedback drives continuous product enhancement.

Real Photos and Packaging

Perfect Applications Across Industries

This versatile equipment serves multiple sectors effectively. Pharmaceutical factories rely on our machines for consistent tablet production. Health product manufacturers appreciate the precision and reliability.

Hospital preparation rooms benefit from the compact design and user-friendly operation. Food factories use our equipment for supplement tablet production. Chemical plants find applications in specialized tablet manufacturing.

The food supplement and health product sectors particularly value our quality standards. Regulatory compliance is built into every design element. Your products will meet strict industry requirements.

Application Areas and Suitable

Technical Excellence You Can Trust

The compact footprint fits most production spaces efficiently. Despite the small size, performance remains uncompromised. Every component is engineered for longevity and reliability.

Maintenance requirements are minimal thanks to robust construction. Simple procedures keep your product running at peak efficiency. Downtime is reduced through thoughtful design choices.

User-friendly controls make operation straightforward. Training time is minimized while productivity is maximized. Your team will quickly master the intuitive interface.

Company Profile

Contact Us

Ready to enhance your tablet production capabilities? Contact our team to discuss your specific requirements for a Single-station tablet making machine. We'll help you select the perfect configuration for your needs.

Our global customer base spans America, Europe, South Africa, Korea, Philippines, and Indonesia. Join this network of satisfied manufacturers who trust Factop equipment.

We're committed to your success through integrity, innovation, and cooperation. Let's build a win-win partnership that drives your business forward.

For detailed specifications and pricing information, reach out to us at michelle@factopintl.com. Our team is ready to support your manufacturing goals with precision equipment and exceptional service.