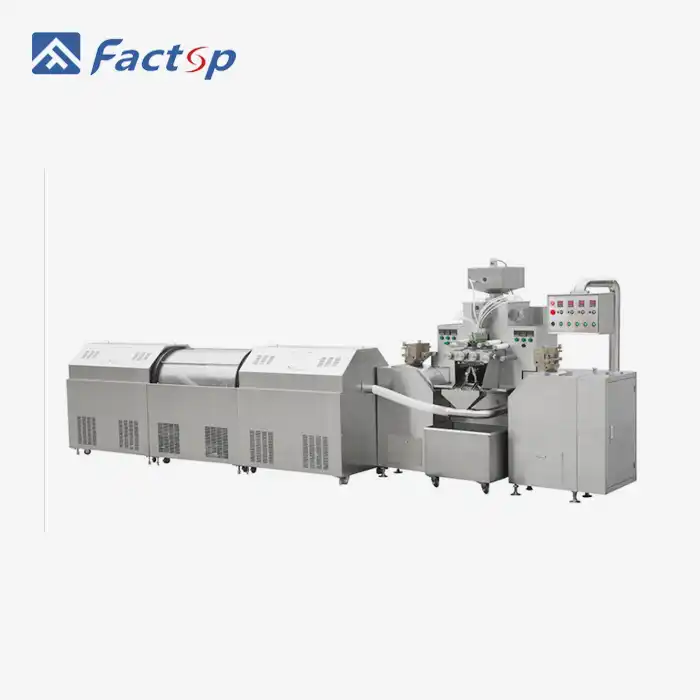

Soft Gel Production Equipment

Max capacity: 147000pcs/hour

Die roller dimension: 150*250mm

Material feeding quantity: 20*(0-2)ml

Delivery time: 30 days

Certificate: CE, GMP, FDA, ISO9001, FAT

Weight: 1500kg

Dimension: 1880*1000*2000mm

Soft Gel Production Equipment: Advanced Capsule Manufacturing Solutions

Are you looking for reliable Soft Gel Production Equipment to streamline your pharmaceutical manufacturing process? A maximum of 147,000 bits per hour can be processed by Factop's HSR-250 machine, which provides excellent performance. For example, CE, GMP, FDA, and ISO9001 badges show that this cutting-edge equipment meets international quality standards. Our high-tech soft gel making equipment guarantees consistent product quality while rising production efficiency and lowering running costs.

Specifications

| Feature | Details |

|---|---|

| Model | HSR-250 Soft Gel Capsule Manufacturing Equipment |

| Production Capacity | Max 147000 soft gels per hour |

| Material Compatibility | Gelatin, HPMC, and other soft gel materials |

| Control System | PLC-based, touch screen interface |

| Power Requirements | 220V/380V, 50Hz/60Hz |

| Material feeding quantity | 20*(0-2)ml |

| Weight | 1500kg |

| Dimensions | 1880*1000*2000mm |

Why Choose Our Softgel Manufacturing Systems?

Superior Production Capacity

This type, the HSR-250, sticks out in the market for pharmaceutical tools. You can meet high-volume needs without sacrificing quality thanks to its amazing hourly output. The 150*250mm size of the die roller makes it ideal for making capsules. Every day, your production line will work better because it will be effective.

Precision Material Handling

Our tools have improved methods for feeding materials. For each pill, the 20*(0-2)ml feeding amount makes sure that the right dose is given. With this level of accuracy, waste is cut down and product stability is maintained. You will like how smoothly it works and how little break there is.

Compact Yet Powerful Design

Despite its robust capabilities, the machine maintains a reasonable footprint. Measuring 188010002000mm and weighing 1500kg, it fits efficiently into most production facilities. The thoughtful engineering maximizes performance while minimizing space requirements.

International Quality Standards

Comprehensive Certification Portfolio

Our Soft Gel Production Equipment meets stringent international standards. CE marking ensures European compliance. GMP certification guarantees pharmaceutical-grade manufacturing standards. FDA approval provides access to global markets. ISO9001 certification demonstrates our commitment to quality management systems.

Factory Acceptance Testing

Before it is sent out, every machine goes through strict FAT testing. This thorough test makes sure that your equipment works as it should from the start. You get detailed paperwork that confirms all success factors.

Complete Support Package

Professional Installation Services

Our skilled expert staff helps with installation and testing on-site. For the best speed and setting, they make sure everything is set up correctly. Training helps your workers get the most out of your tools. This wide range of help cuts down on starting time and learning curves.

Extended Warranty Protection

You receive free spare parts for one full year after purchase. This warranty coverage protects your investment and ensures uninterrupted production. Our global service network provides quick response times for any technical support needs.

Secure Packaging and Delivery

All equipment ships in wooden export boxes designed for international transport. This robust packaging protects your investment during transit. Standard delivery time is 30 days from order confirmation.

Softgel Capsule Machine Photo Show

Versatile Application Range

Multiple Industry Applications

Our softgel production tools are used in many different fields. Our equipment is used by pharmaceutical companies to make medicines. Health product companies trust our accuracy when making supplements. Our small size is good for hospital preparation rooms. Our systems are used by food companies to make healthy goods.

Flexible Production Options

The equipment handles various capsule sizes and formulations. Whether producing vitamins, supplements, or pharmaceutical products, you'll find the flexibility needed. Quick changeover capabilities support multiple product lines efficiently.

Application Areas

Technical Excellence and Innovation

Advanced Engineering

Years of manufacturing experience have refined our product design. The engineering team continuously improves performance and reliability. Every component undergoes careful selection and testing. This attention to detail ensures long-term operational success.

User-Friendly Operation

The tools are easy for your team to use because they are intuitive. Interfaces that are easy to use cut down on teaching time and mistakes. For efficient care, maintenance steps are made easier. The total cost of ownership is lower because of these benefits.

Global Partnership Network

International Experience

Factop has established partnerships across multiple continents. Our equipment operates successfully in America, Europe, South Africa, Korea, Philippines, and Indonesia. This global presence demonstrates our commitment to international quality standards and customer satisfaction.

Multilingual Support

Our professional team speaks multiple languages and understands international trade procedures. This expertise ensures smooth project execution regardless of your location. Clear communication throughout the entire process eliminates confusion and delays.

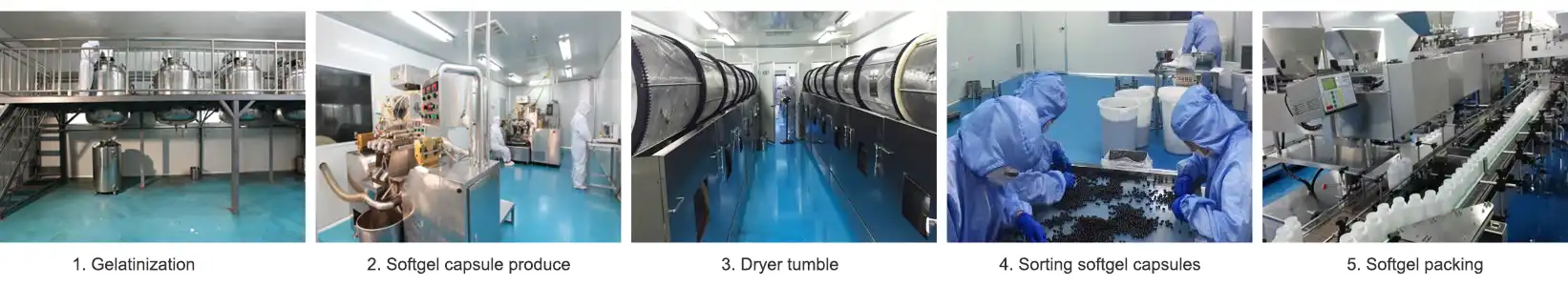

Production Process

Contact Us

Ready to enhance your production capabilities with our Soft Gel Production Equipment? Contact our expert team at michelle@factopintl.com to discuss your specific requirements and receive a customized solution for your manufacturing needs.

YOU MAY LIKE