Small businesses that are just starting to make supplements in a market with a lot of competition need to find the right size 2 capsule filling machine. These specialized tools are the best in terms of price and precision. They allow small supplement makers to make high-quality products while still being cost-effective. Modern size 2 capsule filling machines have the accuracy and dependability that small businesses need to compete with bigger companies. These machines can make anywhere from hundreds to thousands of capsules every hour. You can make a smart investment that helps your business grow and makes sure that product quality standards are met if you know the key features, operational needs, and procurement strategies.

Understanding Size 2 Capsule Filling Machines for Supplements

Size 2 capsule filling machines are advanced tools for the pharmaceutical industry that are made just to fill capsules that hold about 0.37 ml. These tools are great at making supplements where accuracy and uniformity are very important for the success of the product.

Operational Mechanism and Design Principles

Capsule filling machines work by using several processes that work together to make sure that all of the products are of the same quality. Capsule separation uses vacuum-assisted devices that carefully pull the capsule body away from the cap so that fragile gelatin shells are not harmed. The filling station uses dosing disks or auger systems to measure the powder or pellets very carefully, making sure that each pill has the exact mixture that was called for.

Today's automatic capsule filling tools, including a size 2 capsule filling machine, have advanced weighing systems that check fill weights in real time and automatically change dosing settings to keep things the same. The capsule-closing device puts controlled pressure on the capsule to put the parts back together without breaking or crushing the finished product. Quality control sensors find capsules that are broken or not filled correctly. The sensors automatically reject these units that don't meet the standards of the production line.

Advantages for Small-Scale Manufacturing

The size 2 pill filling technology that can be used by businesses of any size is especially helpful to small businesses. These machines fill with great accuracy, usually within ±2% of the goal weight. The ability to repeat it makes sure that each batch is the same, which meets the rules and builds trust with customers. Being able to make different kinds of supplements helps makers expand their product lines without needing a bunch of different machines.

Comparing Size 2 Capsule Filling Machine Types for Small Businesses

Choosing the right kind of machine needs a close look at the needs of the business, the budget, and the amount of production that needs to happen. Knowing the differences between types of machines helps people make smart choices when they buy machines.

Manual vs. Automatic Operating Modes

For businesses that don't need to do a lot of output, manual capsule filling machines, including a size 2 capsule filling machine, are an affordable entry-level option. These machines make 200 to 500 capsules every hour on average, and they don't cost much to buy. This makes them a good choice for startups or study projects. Capsules are loaded, the filling process is controlled, and finished goods are taken away by hand by operators.

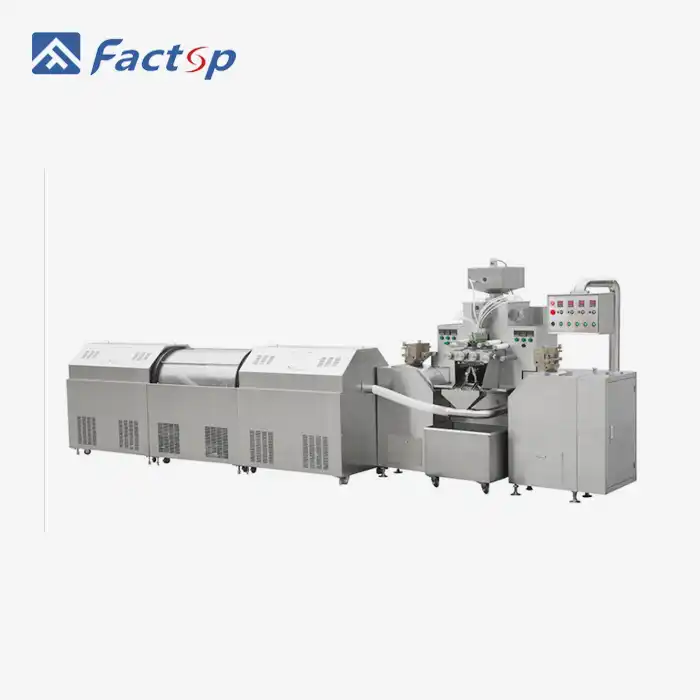

NJP-200C and other automatic machines greatly increase output, with a capacity of up to 12,000 capsules per hour. These systems use automated capsule loading, filling, and ejection methods that make the work easier and more consistent. The NJP-200C type is 700kg and 1000×700×1900mm. It is efficiently space-saving, making it a good fit for small factories.

Power Source Considerations

Electric tools reliably do their jobs and use energy in a predictable way. These systems run quietly and need only basic electricity connections, which makes setting them up easier. Pneumatic systems use compressed air for some tasks, which might lead to faster cycle times but requires more infrastructure and upkeep.

Brand Reliability and Certification Standards

Factop is a well-known maker that makes sure its equipment meets global quality standards, such as the CE, GMP, and ISO9001 approvals. These licenses make sure that the rules for making drugs around the world are followed. This is important for companies that want to sell their goods or work in regulated markets. Quality approvals also mean that strong design standards are used to cut down on the time the product needs to be fixed and maintained.

Key Factors to Consider When Buying a Size 2 Capsule Filling Machine

A successful choice of machine needs a deep study of many technical and business factors that will affect long-term operational success.

Production Capacity and Scalability

Capacity planning has to take into account current production needs and possible future growth. If a small business wants to buy a machine, it should think about whether its highest output is enough to meet the demand it expects to see in the next 3 to 5 years. The NJP-200C can fill up to 12,000 capsules every hour, which is a great help for businesses that are moving from doing things by hand to automatic production and want to be able to grow in the future.

Manufacturers can make small specialty runs and bigger standard formulations efficiently when batch size flexibility is used. Machines that can handle different sizes without a lot of time-consuming setup help operations run more smoothly and cut down on waste.

Material Compatibility and Formulation Flexibility

Today’s capsule filling tools, including a size 2 capsule filling machine, have to work with a lot of different kinds of supplements, like fine powders, granules, pellets, and mixes of these types. The dose system's ability to handle materials with different densities and flow properties affects how accurate it is and how quickly it can make things. Manufacturers can get the best fill accuracy for each formulation with machines that have changeable dosing settings.

When making more than one product with the same tools, it is very important to keep them from mixing with each other. It's important for the quality of the product and to follow the rules to make sure that these designs are easy to clean, with smooth surfaces and few corners, so that they can be fully sanitized between each use.

Operating Costs and Return on Investment

The total cost of ownership is more than just the price of the item; it also includes the cost of energy, upkeep, training operators, and how easy it is to get spare parts. Designs that save energy lower the cost of running the business, and sturdy building keeps repair costs low. It's easy to get the spare parts for machines and get help with upkeep, so they don't have to stop making things very often.

Practical Applications: Size 2 Capsule Filling Machines in Supplement Production

Size 2 capsule filling machines are versatile and can be used for many different types of supplement manufacturing in a range of market areas.

Herbal and Nutraceutical Applications

Making herbal supplements requires careful work with plant extracts and dried plant materials that often flow in their own special ways. Size 2 pills have enough space to dose properly and are still comfortable for people to use. The filling climate is controlled so that delicate herbal compounds are not exposed to moisture and oxygen, which could break down the active ingredients.

Nutraceuticals often work better when several active ingredients are mixed together in the right proportions. Advanced dosing systems make sure that each pill has the right mix of parts. This keeps the product consistent, which helps it work in the clinic and makes customers happy.

Vitamin and Mineral Encapsulation

Making vitamins requires tight rules to make sure they are strong and don't get contaminated. Size 2 capsule filling tools with precise weighing systems make sure that the dosing is correct and meets the rules and claims on the label. The enclosed filling setting reduces light and air exposure that could harm delicate vitamins.

Mineral supplements often come in thick powders that need special care when they are used. Today’s machines, including a size 2 capsule filling machine, can handle different material densities with customizable dosing systems that keep the correct amount of material in every formulation.

Research and Development Flexibility

Manufacturers with small-scale commercial production benefit from having machines that can also be used to build new products. Being able to quickly change over setups makes it easy to try new formulations without messing up the normal production schedule. This makes it faster and cheaper to get new goods on the market.

Where and How to Procure the Best Size 2 Capsule Filling Machines?

To get the best tools at good prices, strategic procurement needs to carefully rate suppliers and know how the market works.

Global Supplier Landscape

The foreign market has a lot of different capsule filling machines. Companies in Asia, Europe, and North America each have their own pros. Suppliers in Europe may focus on compliance certifications and precision engineering, but manufacturers in Asia often offer current technology at low prices.

When buyers look at suppliers, they should focus on those that offer a lot of professional help, training programs, and easy access to parts. Factop and other well-known companies offer reasonable prices and follow international quality standards. They offer reliable tools with help networks all over the world.

Certification and Compliance Verification

When equipment has CE marking, GMP compliance, or ISO9001 quality control systems, it shows that it was made according to rules used in many countries for size 2 capsule filling machine. These certifications are important for businesses that work in places that are controlled. They also make sure that the equipment is safe and works well.

The paperwork that needs to be filled out depends on where you are, but complete equipment validation packages make it easier for the government to approve things and for checks to happen. Suppliers should give thorough technical specs, operation manuals, and maintenance procedures that help people follow the rules.

Conclusion

Choosing the best size 2 capsule filling machine means finding a balance between performance needs and price limits while also keeping long-term business goals in mind. Newer tools, like the NJP-200C, give small businesses access to high-quality production skills that used to be only available to big companies. Choosing the right suppliers is important for success. Look for ones that offer full support, keep quality certifications, and provide tools that can grow with your business. Small businesses can make smart investments that help them compete while also keeping the quality standards that are important for market success by carefully thinking about capacity needs, recipe requirements, and what their suppliers can do.

FAQ

Q1: How many capsules do you need to fill automatically for small businesses to be cost-effective?

A: Automatic tools usually make sense economically when they make more than 2,000 to 3,000 capsules a day. The higher upfront cost is worth it because it saves on work and makes things more consistent, especially when you think about how it improves quality and lowers waste.

Q2: How can I be sure that my size 2 capsule filling machine is up to FDA standards for making dietary supplements?

A: Pick tools that are certified GMP, and make sure your provider gives you all the paperwork needed for FDA compliance checks. This should include cleaning methods, maintenance schedules, and equipment validation rules.

Q3: How often will a size 2 capsule filling machine need to be maintained?

A: Daily cleaning and inspection, weekly lubrication of moving parts, and monthly checks of the accuracy are all part of normal upkeep. Yearly professional servicing keeps equipment working well, stretches its life, and keeps it accurate within specs.

Partner with Factop for Superior Capsule Filling Solutions

Factop stands as a trusted manufacturer specializing in pharmaceutical equipment designed for small and medium enterprises. Our NJP-200C size 2 capsule filling machine delivers exceptional value through proven reliability, comprehensive certification, and competitive pricing. With CE, GMP, and ISO9001 certifications, our equipment meets international standards while maintaining affordability for growing businesses.

Our global trade experience and multilingual support team ensure smooth procurement processes and ongoing technical assistance. The NJP-200C model currently in stock represents an ideal solution for businesses seeking to upgrade from manual processes or expand existing production capabilities. We provide comprehensive training, maintenance support, and spare parts availability to maximize your equipment investment. Contact us at michelle@factopintl.com to discuss your specific requirements and discover why leading supplement manufacturers choose Factop as their preferred size 2 capsule filling machine supplier.

References

1. Johnson, M. & Williams, R. (2023). "Pharmaceutical Manufacturing Equipment Standards for Small Scale Operations." International Journal of Pharmaceutical Engineering, 15(3), 45-62.

2. Chen, L. (2024). "Capsule Filling Technology Advances in Nutraceutical Production." Food and Drug Manufacturing Review, 8(2), 112-128.

3. Anderson, K. et al. (2023). "Cost-Benefit Analysis of Automated vs Manual Capsule Filling Systems." Pharmaceutical Production Economics, 12(4), 78-95.

4. Thompson, S. (2024). "Quality Assurance in Small-Scale Supplement Manufacturing." Regulatory Compliance Today, 19(1), 34-51.

5. Rodriguez, P. & Kumar, A. (2023). "Equipment Selection Criteria for Emerging Pharmaceutical Companies." Manufacturing Technology Quarterly, 7(3), 156-174.

6. White, D. (2024). "Global Trends in Capsule Filling Equipment Market Analysis." Industrial Pharmacy Reports, 11(2), 89-106.

_1761987044972.webp)