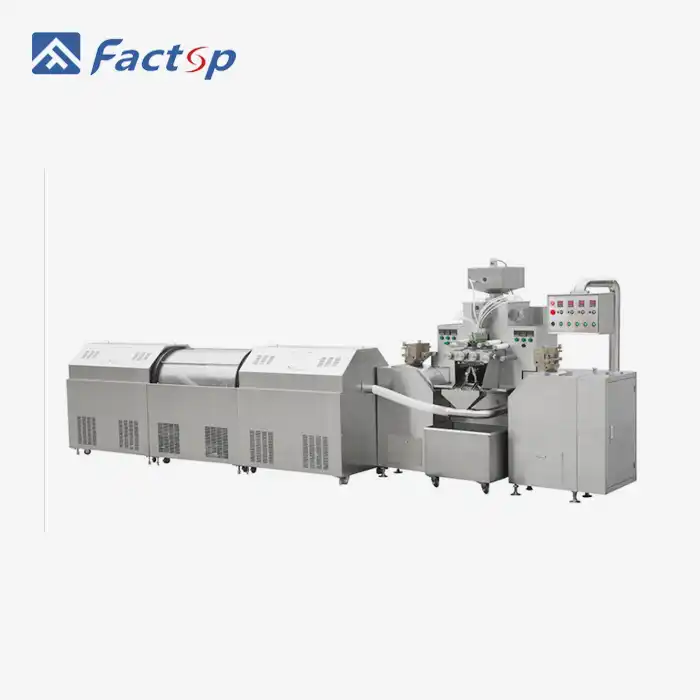

Pillow wrap machine

Working type: Fully automatic

Suitable: Pharmaceutical, food, chemical

Stock: Delivery time 20 days

Material: Stainless steel 304/316

Pillow Wrap Machine: Streamline Your Packaging Operations

Are you looking for efficient packaging solutions for your pharmaceutical, food, or chemical products? Businesses that want the best in automatic packing will love our Pillow wrap machine because it works so well and is so reliable. This fully automatic equipment will change the way you make things because it packs pills, tablets, and other small items in a reliable and professional way. Using cutting-edge technologies and a frame made of stainless steel can help you get better package quality, cut down on labor costs, and greatly increase productivity.

Advanced Features for Maximum Efficiency

The state-of-the-art technology used in our automated wrapping system was created especially for high-volume manufacturing settings. Precision servo motors in the machine provide precise product placement and reliable seal quality. The intuitive touchscreen interface that makes it simple to change parameters and monitor your packing processes in real time will be appreciated by you.

Pharmaceutical applications are ideal for the stainless steel 304/316 structure as it satisfies strict GMP requirements. This long-lasting substance keeps up the hygienic requirements necessary for food and medicinal items while also resisting corrosion. The sturdy construction guarantees dependable performance for many years with no upkeep.

The best sealing conditions for a variety of packing materials are offered by temperature control systems. The machine can adjust to your unique needs whether you're dealing with pharmaceutical-grade materials or regular plastic films. You have flexibility for a range of packaging requirements thanks to many size options that accommodate varying product dimensions.

Key Features

Specifications

| Feature | Details |

|---|---|

| Machine Type | Automatic Pillow Wrap Machine |

| Output Speed | 10-180 bag/min |

| Package Size Range | 30 mm - 100 mm (Width) x 80 mm - 320 mm (Length) |

| Power Consumption | 2.5 kW |

| Voltage | 220V / 50Hz |

| Machine Dimensions | 4700 x 800 x 1550 mm |

| Weight | 500 kg |

| Certification | ISO 9001:2015, CE, GMP Compliant |

Versatile Applications Across Industries

Automated pill packaging features are very beneficial to pharmaceutical producers. In order to avoid product damage during the wrapping process, the system gently and precisely handles tablets, capsules, and soft gels. Features for batch tracking assist with regulatory compliance, which is crucial for the manufacturing of pharmaceuticals.

Uses in the food business include packaging for sweets, vitamins, and other little sweets. Through the use of tight sealing technology, the sanitary design keeps the goods fresh and prevents contamination. Those in the chemical industry love the equipment because of how well it handles granular compounds of all kinds.

Manufacturers of nutraceutical, herbal, and vitamin supplement pills will find this Pillow wrap machine to be an appropriate packaging solution. Various product lines may be accommodated inside a single facility due to the adaptable design, which accepts varying forms and sizes of products.

Application Areas

Quality Construction and Compliance

Your packaging processes will satisfy worldwide pharmaceutical requirements with GMP certification. All steps of production are subject to stringent quality control methods at our factory. Factory Acceptance Testing (FAT) certification ensures that all machines have been thoroughly tested and meet all performance criteria before they are shipped.

When shipped internationally, your investment will be protected by the wooden box export packing. Your equipment will arrive in pristine shape thanks to expert packaging that minimizes the danger of damage during shipment. Speedy setup and commissioning are made possible by comprehensive technical documentation and installation instructions.

Quality components sourced from reputable suppliers contribute to long-term reliability. Precision bearings, high-grade electrical components, and commercial-grade sensors ensure consistent performance under demanding production conditions. Regular maintenance schedules keep your equipment operating at peak efficiency.

Comprehensive Support and Service

Fast delivery within 20 days from our stock inventory gets your production line operational quickly. Our experienced team coordinates shipping logistics to minimize delays and ensure timely arrival at your facility. Express shipping options are available for urgent requirements.

On-site installation and commissioning support guarantees proper setup and optimal performance. Our qualified technicians provide comprehensive training for your operators, ensuring they understand all machine functions and safety procedures. This hands-on approach minimizes startup issues and accelerates full production capability.

Free spare parts for one year protect your investment and reduce operating costs. This comprehensive warranty covers wear components and critical parts, giving you peace of mind during the initial operating period. Our international service network provides ongoing technical support when needed.

Technical Specifications and Customization

The fully automatic operation reduces labor requirements while improving packaging consistency. Programmable settings allow quick changeovers between different products, maximizing production flexibility. Speed controls accommodate various production rates, from small batches to high-volume runs.

Safety features include guards, emergency stops, and tracking systems that use sensors. These parts keep workers safe and keep tools from getting damaged by bad operation. Following international safety standards is the only way to make sure that the workplace is safe in any industrial setting.

Options for customization Change the product so that it fits your needs. For each application, specialized feeding systems, custom tools, and changed control factors improve performance. Our tech team works closely with clients to come up with solutions that are just right for them.

Delivery & Samples

Investment Benefits and ROI

Compared to wrapping things by hand, automated packing uses a lot less work. Consistency in the quality of wrapping makes products look better and cuts down on waste from broken packages. Overall output goes up when production speeds go up, which lets you meet growing demand well.

Design that uses less energy keeps efficiency high while lowering running costs. These days, servo motors use less power than older methods, which helps keep energy costs down. Total running costs over the life of the machine go down even more because it needs less repair.

If you package your products professionally, it makes your brand look better and makes customers think the products are better quality. It keeps goods safe while they're being stored and shipped when the seal is always intact, which cuts down on returns and customer complains. Many customers are happier and come back to buy from you again because of these perks.

Contact Us

Ready to transform your packaging operations? Contact our experienced team at michelle@factopintl.com to discuss your specific requirements and discover how our Pillow wrap machine can enhance your production efficiency today.

YOU MAY LIKE