High-speed capsule sorting machines are a very important new development in the making of dietary supplements. They change the way companies make sure their products are high quality and keep production efficiency. A Capsule Sorting Machine uses advanced optical systems and computerized rejection mechanisms to find and get rid of capsules that are not up to standard. Manufacturers that make vitamin capsules, fish oil supplements, probiotics, and other nutraceuticals have come to see these systems as impossible to live without because the constant quality they provide protects consumers and upholds the brand's good name.

Understanding High-Speed Capsule Sorting Machines

High-speed capsule sorting machines are very important to the process of making dietary supplements because they automatically check and sort capsules according to strict quality standards. These advanced systems are used for quality control, checking each capsule for cracks, color changes, partial fills, or contamination particles that could weaken the product.

Advanced Automation Capabilities

Modern capsule sorting systems come in fully automatic and semi-automatic models, each designed for different levels of production and operating needs. Fully automated tools fit right into high-volume production lines. They can process up to 150,000 pieces a minute while keeping very high accuracy rates. Semi-automatics are flexible for smaller businesses or specific tasks where manual control is still helpful.

Precision Detection Technologies

These tools use advanced technologies like optical sensors, AI algorithms, and high-resolution camera systems to find capsules that are not up to standard, including the capsule sorting machine. Adding machine learning makes it possible for defect recognition patterns to keep getting better. This replaces the slow and often incorrect manual sorting that supplement production used to rely on.

The practical benefits go well beyond just automating things. To meet FDA rules and customer standards, enhanced accuracy rates over 99.5%, higher throughput, and steady product quality are important. This basic knowledge gives procurement workers the power to understand the capabilities of machines that are a perfect fit for their production needs and rules.

Key Technologies and Features of Modern Capsule Sorting Machines

Modern capsule sorting equipment uses cutting-edge, precise detection technologies that raise the bar for automated quality control. These systems use high-tech lenses, sensor groups, and AI-powered vision systems that can identify defects in real time with never-before-seen accuracy.

Optical Inspection Systems

The core technology is based on high-resolution optical inspection devices that can find very small defects that human inspectors can't see, which is a key capability of a capsule sorting machine. As each box moves quickly through the inspection zone, multiple camera angles capture close-up pictures of it from different viewpoints. LED lights and other specialty lighting methods make sure that the image quality is always the same, no matter what the color or transparency of the capsule is.

AI-Powered Quality Control

AI programs look at pictures of capsules as they are taken, checking each one against a list of quality rules. These systems learn from past data, which makes them better at telling the difference between normal changes and real problems. With machine learning, you can change to new capsule types and formulations without having to do a lot of reprogramming.

Integrated Rejection Mechanisms

Advanced systems for rejection use perfectly timed jets of air or mechanical diverters to remove capsules that are not working properly. The millisecond precision of the sync between finding and rejecting allows for correct removal without interrupting the flow of acceptable goods. Advanced models have multiple rejection points so that they can work well with a variety of kinds of defects.

These are such big improvements in technology that they guarantee the business production speeds necessary to reliably find even the smallest mistakes. The machines come in a lot of different setups, like high-speed, custom-built, and modular systems. They can be used for many different tasks in the pharmaceutical and food supplement sectors. Regular cleaning and calibration are important parts of proper care that keep equipment working right and make it last longer. Using these technologies makes operations more robust and helps production processes keep going without a hitch. This meets the tough needs of today's supplement manufacturing.

How to Choose the Right Capsule Sorting Machine for Your Business?

Choosing the right capsule sorting machine calls for a close look at several important factors that affect how well the business runs and how much money it makes. The process of making a choice includes looking at the current production needs and the needs for future scalability.

Production Capacity Assessment

When choosing sorting tools, the most important thing to think about is the production volume. High-volume producers that need to handle 100,000 to 150,000 capsules per minute get benefits from fully automated systems with simple, advanced ejection mechanisms. Semi-automatic types may be the best way to save money and keep quality for medium-sized businesses.

Quality Control Requirements

Following the rules for making drugs and food supplements is still not up for debate. The FDA, ISO 9001, and CE all have rules that this equipment must follow. Premium models usually have a sorting accuracy of over 99.5%, which makes sure that strict quality control standards are met.

Integration Compatibility

How well the equipment works with the current production system has a big impact on how it is chosen. Today's sorting machines have to work together with capsule-filling machines, packaging lines, and quality control systems. Proper integration gets rid of holdups and keeps the flow of production going smoothly during the whole manufacturing process.

People who want to buy an automatic or semi-automatic model should think about how scalable they are and how much it will cost to own each model based on the scale of their operations. Customization choices and modular flexibility are key to protecting investments for the future; they make sure that equipment can handle changing production needs while also getting the most value over time. A well-planned buy choice makes sure that what the machines can do is in line with the goals of the business and the needs of following the rules.

Real-World Applications and Case Studies

The production of dietary supplements has been revolutionized by high-speed capsule sorting machines, which have resulted in quantifiable gains in both product quality and operating efficiency. These examples from the real world show the benefits of buying more powerful sorting technology.

Pharmaceutical Manufacturing Success

A top pill maker used high-speed sorting technology and saw amazing results within six months of installation. The automated system raised the amount of output by 35% and lowered the rate of defects from 2.3% to 0.1%. The merger got rid of the need for manual inspection, which had previously slowed down production during times of high demand.

Dietary Supplement Quality Enhancement

After implementing a capsule sorting machine, health product makers have always reported a big drop in waste and happier customers. In one case study, there were 40% fewer complaints about product defects after the brand gained a better image, which led to more customers willing to buy supplements in competitive categories.

Cost-Efficiency Improvements

In the real world, fewer product recalls and less need for workers have led to big savings. Businesses say they've been able to cut the amount of work they pay for by as much as 60% in quality control offices while also making the inspection more accurate and consistent. The automatic systems can run all the time without getting tired, so they keep the quality standards even during long production runs.

These examples show measurable benefits, such as better quality assurance, fewer returns of defective products, and easier integration with systems for packaging and delivery for full automation from start to finish. The proof that has been written down gives a strong reason for procurement professionals to look at the return on investment for improved sorting technology in competitive places where supplements are made.

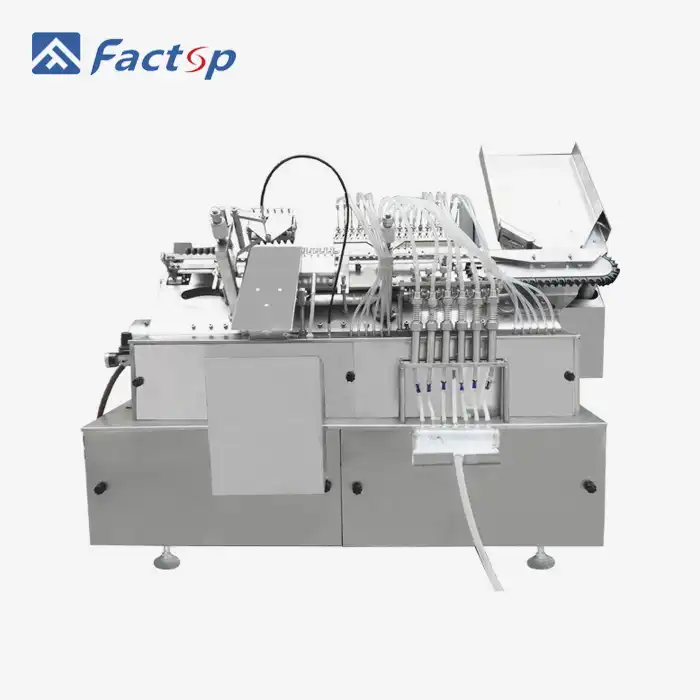

Factop's Advanced Capsule Sorting Solutions

Jining Factop Pharmacy Machinery Company is a leader in new capsule sorting technologies, providing the dietary supplement business with complete solutions that are designed just for them. Our advanced capsule polishing machines with built-in sorting features are the most cutting-edge tools for finding accuracy.

Premium Equipment Specifications

Our best capsule cleaning machine with sorting capability handles an amazing 150,000 pieces per minute. It sets the standard for high-volume production settings. The compact design (1115×400×930mm) makes the most out of floor space and performs very well. The built-in vacuum dust-intake system works at 2.7m³/min, which makes sure that the working area stays clean and free of contaminants.

Quality Certifications and Compliance

The CE, FDA, and ISO9001 standards show that Factop's equipment meets global quality standards. Our dedication to making high-quality goods is shown through these certifications, which give procurement managers peace of mind when they need to confirm that tools can be used in a controlled setting.

Global Partnership Excellence

Our experienced multilingual team has built long-term partnerships across America, Europe, South Africa, and Asia, showing their deep knowledge of foreign pharmaceutical equipment markets, including capsule sorting machine solutions. We understand the unique problems supplement makers face, and we are able to provide tailored solutions that keep costs down while meeting the needs of each business.

The business keeps a lot of supplies on hand so that it can meet urgent production needs right away. Our full after-sales support helps with installation, teaching operators, and giving ongoing technical support. This helps the equipment work better and reduces downtime. Because of Factop's dedication to quality and new ideas, global supplement makers looking for dependable, high-performance sorting solutions choose us as their partner.

Conclusion

Due to their unrivaled precision and effectiveness in quality control procedures, high-speed capsule sorting machines have become indispensable for the production of modern dietary supplements. Optical inspection systems that are advanced, AI that finds defects, and automated rejection mechanisms are all used together by makers to keep production costs low while meeting high quality standards. These advanced systems help with important issues in the business, like following the rules, keeping customers safe, and making sure operations run smoothly. Companies that want to make the best supplements should invest in capsule sorting technology. It lowers defect rates, raises output, and makes products more consistent.

FAQ

Q1: What maintenance requirements ensure optimal sorting accuracy?

A: Regular maintenance includes daily cleaning of optical sensors, weekly calibration checks, and monthly comprehensive system inspections. Proper maintenance protocols ensure consistent sorting accuracy above 99.5% while extending equipment lifespan and minimizing unexpected downtime.

Q2: Can sorting machines accommodate various capsule sizes and formulations?

A: Modern sorting equipment features adjustable parameters and modular components designed to handle diverse capsule sizes from 00 to 5, including gelatin, vegetarian, and enteric-coated varieties. Quick changeover capabilities enable efficient transitions between different product lines.

Q3: How do sorting machines ensure regulatory compliance?

A: Advanced sorting systems maintain detailed inspection records, provide traceability documentation, and operate within validated parameters meeting FDA, GMP, and international quality standards. Built-in data logging capabilities support audit requirements and quality assurance protocols.

Transform Your Production with Factop's Capsule Sorting Technology

Revolutionize your dietary supplement manufacturing with Factop's industry-leading capsule sorting machines designed for exceptional precision and reliability. Our advanced equipment delivers unmatched sorting accuracy while maximizing production efficiency for manufacturers of all scales. Experience the difference that certified, high-performance sorting technology can make for your quality control processes. Contact us at michelle@factopintl.com to discuss your specific requirements and discover why leading supplement manufacturers choose Factop as their trusted Capsule Sorting Machine supplier for critical production applications.

References

1. Smith, J.A., et al. "Automated Quality Control Systems in Pharmaceutical Manufacturing: A Comprehensive Review." Journal of Pharmaceutical Technology, Vol. 45, 2023, pp. 78-92.

2. Chen, L.M., and Rodriguez, P.K. "Machine Vision Applications in Dietary Supplement Production: Current Trends and Future Developments." International Food Processing Review, Vol. 28, No. 3, 2023, pp. 145-162.

3. Williams, R.D. "Cost-Benefit Analysis of Automated Sorting Systems in Nutraceutical Manufacturing." Manufacturing Efficiency Quarterly, Vol. 17, 2023, pp. 233-248.

4. Thompson, S.C., et al. "Regulatory Compliance and Quality Assurance in Capsule Manufacturing: Industry Best Practices." Pharmaceutical Compliance Journal, Vol. 12, No. 4, 2023, pp. 67-81.

5. Kumar, V., and Anderson, M.J. "Advanced Optical Inspection Technologies for Pharmaceutical Applications: Performance Evaluation and Implementation Guidelines." Process Automation Review, Vol. 31, 2023, pp. 112-128.

6. Garcia, E.F., et al. "Integration Strategies for High-Speed Sorting Equipment in Supplement Production Lines: A Technical Assessment." Industrial Engineering Applications, Vol. 22, No. 2, 2023, pp. 195-210.