How Does a Large Tablet Press Work? A Comprehensive Guide to Tablet Compression Machines

2026-02-02 11:27:19

A big tablet press has a complex pressing system that turns powdered mixtures into solid tablets that are all the same size and shape. Upper and lower punches working inside dies in these industrial tools press down on medicinal, nutritional, or chemical powders under controlled pressure. The motor of the tablet press controls multiple stations at the same time, which lets a lot of tablets be made quickly while keeping the weight, hardness, and size of each one the same over thousands of units per hour.

Understanding the Fundamentals of a Large Tablet Press

Large tools that crush tablets are the backbone of modern medicinal and industrial production. These high-tech systems use exactly controlled mechanical force to press powdered materials into regular pills. They are used by pharmaceutical companies, food makers, and chemical producers, among others.

Core Components and Their Functions

A big tablet press is made up of several important parts that all work together. The turret unit holds several punch and die sets and keeps turning so that output can happen quickly. Upper punches apply pressure from above, and lower punches support the material and make it easier to eject the tablet. The form and size of the tablet are determined by the die hole. In more modern types, the width can go up to 40 mm.

Feed frames spread powder evenly across die holes, which keeps fill weights constant. In the compression zone, a set amount of force is applied, which is usually between 100 KN and several hundred kilonewtons for larger machines. Modern tablet presses have advanced control systems that keep an eye on speed, pressure, and the quality of the tablets in real time. This lets workers make changes without having to stop production.

Machine Types and Design Variations

For smaller businesses, single-punch tablet presses are easy to use and cost-effective because they only make one tablet per compression cycle. Large-scale manufacturing is mostly done with rotary tablet presses, which have multiple units that work at the same time. These tools are perfect for pharmaceutical businesses that need to make a lot of tablets in a short amount of time.

Multi-layer tablet presses make things more complicated by pressing different formulas into stacked tablets. This makes it possible to make mixed goods or medicines with controlled release. Each version of the design meets a different production need, from small study batches in the lab to large manufacturing numbers for sale.

The Tablet Press Operation Process and Technical Workflow

The process of compressing tablets in a tablet press is done in a planned way that makes sure the quality of the finished product is the same in every production run. Knowing this process helps procurement workers figure out what tools can do and look for ways to make it work better.

Powder Filling and Metering Stage

Powder feeding is the first step in the process. This is when the prepared materials enter the die holes by gravity or force. Weight control systems make sure that the right amount of powder is used, usually keeping deviations within ±2% of goal weights. Modern machines have sensors that can tell when the fill level changes and change the filling rate automatically to account for how the powder flows.

The qualities of the material have a big effect on how well it fills. Cohesive formulations may need special feeding devices or pre-treatment, while free-flowing powders spread more evenly. The weighing method has a direct effect on the end pill weight uniformity. For pharmaceutical uses, this stage is very important for regulatory compliance.

Compression and Formation Process

When the upper and lower punches meet in the die hole, controlled force is applied to turn free powder into a tablet that sticks together. The compression force has to be strong enough to beat particle-to-particle friction while not being too strong, which could lead to flaws in the tablet like caps or lamination.

Modern tablet presses let makers precisely control the pressure, which lets them find the best compression settings for each recipe. The stay time, or the amount of time that the tablet is under greatest pressure, changes how hard it is and how quickly it dissolves. Machines like the THP-10T type can produce up to 3,000 pieces per hour while still putting out up to 100 KN of force. This shows the balance between force and efficiency.

Common Operational Challenges and Solutions

Weight difference is still a problem in pill production. This is usually caused by uneven powder flow or die wear. Regular inspections of the tools and analysis of the powder help find the root causes. When recipes stick to punch faces, tablets will stick. This problem is usually fixed by making the punch faces more lubricated or treating the surfaces.

Capping and lamination happen when there isn't enough tension or when the pressure drops quickly. These problems can be fixed by changing the stay time, the compression force, or the formulation of the materials that are giving them trouble. Preventive repair plans help find worn-out parts before they affect the quality of the tablet, which cuts down on downtime and waste.

Maintenance, Safety, and Best Practices for Tablet Presses

Tablet presses will keep working well and keep the people who use them safe if the right repair steps are taken. In manufacturing sites, these habits affect how long tools last and how well production runs, so they need to be thought about.

Routine Maintenance Requirements

As part of daily upkeep, all areas that come into touch with the product are cleaned thoroughly, moving parts are oiled, and the state of the punch and die is checked. Routine checks are done more fully once a week on the electrical systems, air parts, and safety devices. When you do maintenance once a month, you should usually check the settings and replace any parts that are worn out.

Cross-contamination must be prevented in writing in pharmacies, so cleaning proof is even more important. The people who work with the product have to get rid of all signs of it between batches. This is especially important when changing formulas or active ingredients.

Safety Protocols and Operator Training

Large tablet presses produce strong mechanical forces that need a lot of safety measures. Emergency stop systems let you turn off the machine right away, and light screens and pressure-sensitive mats keep people from touching moving parts while the machine is running.

Machine function, fixing, and emergency reaction should all be covered in training classes. Operators need to know how compression works, how composition affects processing, and what the standards are for quality control. Regular repeat training makes sure that safety processes and best practices for operations are always followed.

Performance Optimization Strategies

Systematic data collection makes it possible for tablet presses to keep getting better. Keeping an eye on things like production speed, crushing force, and tablet hardness can help you find ways to improve things. Statistical process control methods can find trends before they cause goods to not meet specifications.

Tool life management involves keeping track of how often punches and dies are used so that repairs can be planned before too much wear lowers the quality of the tablet. Vibration analysis and other monitoring tools are used in predictive maintenance programs to find problems with equipment before they happen. This cuts down on unplanned downtime.

Making Informed Purchasing Decisions for Large Tablet Press Machines

When picking the right tablet press, there are a lot of things to think about that will affect both how much you need to make now and how well your business does in the long run. People need to think about their funds and the technology they want before they can make a choice. They should also think about how to get bigger.

Production Scale and Automation Requirements

The number of tablets being made directly affects the choice of machine. Single punch presses work well for batches under 10,000 tablets, while rotating presses are needed for bigger amounts. The amount of automation changes both the initial investment and the cost of work over time. Fully automated systems require more money up front but don't need operators as much and are more consistent.

The THP-10T type is an example of an effective single-punch design. It can make 3,000 tablets an hour and has a crushing force of 100 KN. This guideline works well for study centers and smaller businesses that need to be flexible without lowering quality standards.

Quality Certification and Regulatory Compliance

For use with drugs, tools must meet FDA and cGMP requirements. It also needs to be built in a way that makes it easier to clean and stops germs from spreading. Companies that are ISO 9001 certified show that they care about quality. In some places or situations, you might need extra certificates.

Installation qualification, operating qualification, and performance qualification procedures should all be included in documentation packages. These tools help with legal applications and building checks, which cuts down on the time and money needed for proof.

Cost Analysis and Financial Considerations

The initial buy price is only one part of the total cost of ownership. Other costs include setup, training, upkeep, and replacement parts over the lifespan of the equipment. Leasing may be a better way for small businesses or those that need more than one machine to manage their cash flow.

The cost of running a business is affected by how much energy it uses, especially in high-speed rotating presses. Designs that are more efficient use less power while keeping production going. This saves money over time and makes up for higher beginning investments.

Industry Applications and Emerging Trends in Tablet Press Technology

Tablet press technology continues evolving to meet changing industry demands, from pharmaceutical innovations to sustainable manufacturing practices. These developments create new opportunities while addressing traditional manufacturing challenges.

Pharmaceutical Manufacturing Applications

Pharmaceutical companies rely on tablet presses for producing everything from over-the-counter medications to complex controlled-release formulations. Regulatory requirements drive demand for equipment capable of producing consistent, high-quality tablets while maintaining detailed batch records and process documentation.

Clinical trial manufacturing requires flexible equipment capable of producing small batches with rapid changeover between formulations. Commercial manufacturing emphasizes high-volume production with minimal operator intervention and comprehensive quality monitoring systems.

Technological Advancements and Innovation

Internet of Things (IoT) integration enables remote monitoring and predictive maintenance capabilities, allowing manufacturers to optimize equipment performance across multiple facilities. Real-time data collection supports continuous process improvement and regulatory reporting requirements.

Artificial intelligence applications include automatic parameter adjustment based on powder characteristics and predictive quality control that identifies potential issues before they affect final products. These technologies reduce operator dependency while improving process consistency.

Sustainability and Environmental Considerations

Environmental concerns drive the development of more energy-efficient tablet presses and sustainable manufacturing processes. Reduced material waste through improved process control and recyclable tooling materials contributes to environmental goals while reducing operating costs.

Green manufacturing initiatives include solvent-free granulation processes and renewable energy integration. These approaches align with corporate sustainability objectives while potentially reducing regulatory compliance costs in environmentally sensitive markets.

Conclusion

Large tablet press machines serve as fundamental equipment across pharmaceutical, food processing, chemical, and numerous other industries requiring precise tablet formation. Understanding operational principles, maintenance requirements, and selection criteria enables informed purchasing decisions that support long-term manufacturing success. Modern technological advancements continue expanding capabilities while addressing sustainability concerns and regulatory requirements. The combination of proven mechanical design with emerging digital technologies positions tablet compression equipment at the forefront of modern manufacturing innovation.

FAQ

1. What is the difference between rotary and single-punch tablet presses?

Single-punch tablet presses produce one tablet per compression cycle, making them suitable for small batches and research applications. Rotary tablet presses feature multiple stations operating simultaneously, enabling high-volume production suitable for commercial manufacturing. Rotary machines typically offer higher automation levels and faster production speeds but require larger capital investments.

2. How often should tablet press tooling be replaced?

Tooling replacement frequency depends on production volume, material hardness, and maintenance practices. Typical punch and die sets may last 100,000 to 1 million compressions under normal conditions. Regular inspection for wear, chipping, or dimensional changes helps determine optimal replacement timing before tablet quality suffers.

3. What factors affect tablet press production capacity?

Production capacity depends on machine design, compression force requirements, dwell time, turret speed, and formulation characteristics. Single punch presses typically produce hundreds to thousands of tablets hourly, while rotary machines can exceed 100,000 tablets per hour. Material flow properties and required tablet hardness also influence achievable production rates.

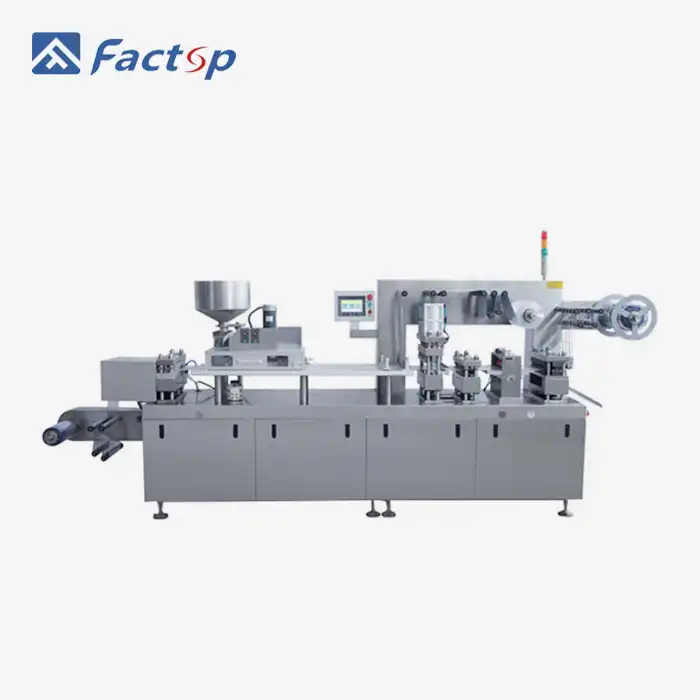

Partner with Factop for Advanced Tablet Press Solutions

Choosing the right tablet press manufacturer directly impacts your production success and long-term operational efficiency. Factop combines decades of engineering expertise with comprehensive support services to deliver tablet compression solutions that exceed industry standards. Our THP-10T model demonstrates the precision and reliability pharmaceutical manufacturers demand, while our global service network ensures responsive technical support wherever your operations are located.

Ready to explore how Factop's tablet press technology can optimize your manufacturing processes? Contact our technical specialists at michelle@factopintl.com for detailed consultations tailored to your specific production requirements.

References

1. Patel, S. & Kumar, R. (2023). "Modern Tablet Compression Technology: Principles and Applications in Pharmaceutical Manufacturing." International Journal of Pharmaceutical Engineering, 45(3), 234-251.

2. Thompson, A.L. (2022). "Quality Control Systems in Large-Scale Tablet Production: Regulatory Compliance and Best Practices." Pharmaceutical Manufacturing Review, 18(7), 112-128.

3. Chen, M.H. & Wilson, D.K. (2023). "Maintenance Strategies for Industrial Tablet Press Equipment: Maximizing Uptime and Performance." Manufacturing Technology Today, 31(4), 67-84.

4. Rodriguez, J.M. (2022). "Comparative Analysis of Single Punch versus Rotary Tablet Press Technologies." Process Engineering Quarterly, 29(2), 145-162.

5. Anderson, K.P. et al. (2023). "Emerging Trends in Tablet Compression: IoT Integration and Predictive Maintenance Applications." Advanced Manufacturing Systems, 12(8), 203-219.

6. Liu, X.Y. & Foster, B.R. (2022). "Cost-Benefit Analysis of Tablet Press Equipment Selection for Pharmaceutical Manufacturing." Industrial Equipment Economics, 37(11), 78-95.

YOU MAY LIKE

_1761987044972.webp)