High Capacity Vitamin Tablet Press Machines for Efficient Nutraceutical Production

2026-02-02 11:27:12

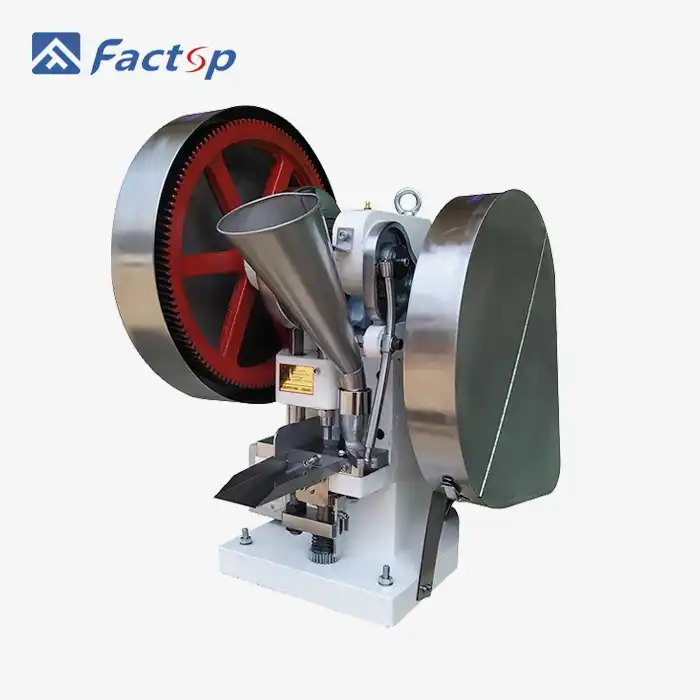

High-volume vitamin pill press machines are the most important part of modern nutritional manufacturing because they can make a lot of vitamins quickly, accurately, and reliably. Through advanced compression technology, these complex systems turn powdered nutrients into uniform, high-quality pills. This change is shown by our Factop THDP-6 Vitamin Tablet Press Machine, which can make tablets with a width of 5–18 mm and has CE, GMP, and ISO9001 certificates. It was made for food companies, vitamin makers, and supplement production facilities that want to be more productive.

Understanding High-Capacity Vitamin Tablet Press Machines

When we look at the scene of nutrition manufacturing, high-capacity vitamin pill press machines stand out as the workhorses that help companies meet the huge demand for healthy supplements from customers. The unique thing about these tools is that they can make thousands of tablets an hour while keeping pharmaceutical-grade accuracy in every single one.

Defining High Capacity Specifications

A machine is considered "high capacity" based on a number of important performance indicators that have a direct effect on how efficiently it produces goods. Depending on the size of the pill, the complexity of the mixture, and the way the machine is set up, output rates can be anywhere from 50,000 to over 500,000 per hour. The compression force can be more than 100 kN per station, which makes it possible to work with difficult materials like magnesium oxide or calcium carbonate that need a lot of pressure to form tablets properly.

Levels of automation are also a big part of figuring out capability. Modern high-capacity systems have advanced programmable logic controllers (PLCs) and touchscreen displays that let workers see real-time information like changes in tablet weight, hardness readings, and the spread of compression force. These systems change the feeding rates, compression time, and release forces automatically to keep the quality of the product the same over long production runs.

Rotary vs. Single Punch Press Technologies

Both rotating and single-punch presses are very different in how they are built, which makes them very different for making large amounts of nutraceuticals. Multiple punch and die stations are set up in a circle on rotary tablet presses so that tablets can be made continuously as the turret turns. This design lets different stations do filling, compression, and release at the same time, which makes the flow rates much higher than with single-punch options.

Although single-punch presses are more precise for some tasks, they can only make 500 to 3,000 tablets per hour on average. These tools work great in research and development settings where trying new recipes needs to be done in small batches with precise control of parameters. The Factop THDP-6 model fills this gap by being very flexible in both research and production situations. It can handle pill sizes ranging from 5 mm to 18 mm while still keeping the level of accuracy needed for making vitamins.

Essential Components and Safety Features

Manufacturers can better understand how difficult it is to make consistent tablets when they know about the important parts of high-capacity vitamin tablet presses. The die and punch unit is the main part of the system. It's where the powder is compressed under very precise control. When working with rough vitamin mixtures that contain minerals or man-made chemicals, high-quality cutting materials like tungsten carbide or specific steel alloys ensure longer tool life.

Modern vitamin tablet press machines have a lot better safety methods than older ones did. They protect both the workers and the tools in many ways. Accidents can be avoided with emergency stop devices, light screens, and pressure tracking monitors. These also keep expensive tools from getting damaged. When making vitamins, the unique problems that come up are dealt with by dust control systems. Fine powders can be dangerous for the lungs, and there is a chance that different supplement formulas could become contaminated.

Comparing Different Types of Vitamin Tablet Press Machines for Nutraceutical Production

In the tough nutritional market, choosing the right tablet press technology has a big effect on both short-term output skills and long-term business success. Different types of machines have different benefits that make them better for different types of production needs, from new businesses starting out to large companies expanding to meet rising demand.

Rotary vs. Single Punch Performance Analysis

Rotary tablet presses are the most common way to make large amounts of nutraceuticals because they are so efficient and can handle a lot of tablets at once. These machines can usually make 10 to 50 times as many units as single-punch machines. This is why companies that make famous products like multivitamins, vitamin D3, or omega-3 formulations need them every day to make hundreds of thousands of units. The concept of ongoing operation cuts down on material waste and labor costs per thousand pills made.

Even though they cost more to buy at first, rotating systems are better for large-scale production because they are cheaper to run. Higher numbers use a lot less energy per pill, and the automatic feeding and release systems cut down on the amount of work that needs to be done by hand. How often maintenance is done depends on how much is being made and what kind of material it is, but modern rotary presses are made in a way that lets them quickly switch between different vitamin formulas without a lot of downtime.

Single-punch tools are still useful in certain situations where accuracy is more important than speed. When making high-value nutraceuticals with complicated release profiles, enteric coatings, or unique forms that need careful attention to compression factors, these systems really shine. Single-punch technology is useful for custom recipe development and small-batch specialty supplements because it lets you change the properties of each pill individually.

Electric vs. Pneumatic System Comparisons

When making vitamin tablets, the choice between electric and gas drive methods affects both how flexibly the machine can be used and how much it will cost to maintain over time. Electric servo-driven systems give makers more precise control over the pressing force, which lets them make tablets that are the right hardness and dissolve faster for different vitamin formulations. Electric systems have exact speed controls that let you fine-tune the stay time, which is very important when working with vitamins or probiotics that need to be handled carefully and at a low temperature.

How much energy these systems use is very different from one another. During continuous operation, electric systems usually work more efficiently because they directly turn electrical energy into mechanical compression force without the costs that come with making compressed air. Pneumatic systems are better in places where there is already equipment for compressed air because they lower the cost of installation and make upkeep easier.

Electric systems offer the most operational freedom because they can quickly switch between different vitamin goods thanks to customizable parameters. By storing different compression settings, makers can quickly switch from making vitamin C tablets to calcium supplements, making the most of their tools across a wide range of products.

Station Configuration Impact on Production Speed

The amount of production and the amount of money needed to buy tools are directly related to the number of compression units in rotary tablet presses. Ten-station machines are a great choice for medium-sized supplement makers because they are both affordable and good at getting the job done. These systems can make between 50,000 and 150,000 pills an hour, based on the size and composition of the tablets. This makes them good for regional supplement brands or contract makers who work with many customers.

With sixteen-station setups, these machines can make 200,000 to 400,000 pills per hour, making them perfect for big vitamin companies that sell to customers across the country or around the world. The extra stations allow for faster speeds while still allowing enough rest time for proper compression. This is especially important when working with difficult materials like pills with multiple active ingredients or sustained-release vitamin formulas.

Scale issues in business go beyond the current output needs and include Vitamin Tablet Press Machine plans for future growth. Companies that are seeing their markets grow quickly often do better by investing in more stations at first. This way, they don't have to deal with the hassle and cost of replacing equipment as demand grows. Modern tablet presses are flexible, which means that their capabilities can be slowly increased by adding new tools and making the machinery better.

Maintenance, Troubleshooting, and Capacity Optimization Tips

Nutraceutical production depends on good upkeep plans that keep pill quality uniform and machine uptime at its highest level. Because vitamin pill production is so difficult, with different formulas and strict quality standards, it needs proactive upkeep methods that keep production from stopping, which would cost a lot of money.

Essential Maintenance Practices

High-capacity vitamin pill presses need regular repair in a number of important areas that work together to make sure they work at their best. Daily cleaning routines get rid of any leftover powder and keep different supplement formulas from getting contaminated. The unique problem with making vitamins is that they need a lot of different things to be made. Some vitamins, like those that dissolve in water, can harden when it's wet, and vitamins that dissolve in fat can leave a sticky film on machines.

To stick to plans for lubrication, you need to make sure the oils are safe for food, allowed by the FDA, and up to healthy production standards. Turret bearings, cam followers, and release systems are all important places to lubricate because they are constantly under stress during high-speed production. How often greasing is done depends on how much is being made. For example, high-capacity processes need to be oiled every day to make sure they run smoothly.

Procedures for calibration keep the accuracy needed to keep pill weight and stiffness the same throughout production runs. These days, tablet presses have electronic tracking systems that keep track of changes in compression force and let workers know about possible problems before they affect the quality of the product. Regularly calibrating these sensors stops movement that could lead to batches being refused or finished vitamins not dissolving properly.

Common Troubleshooting Solutions

One of the most common problems with making a lot of vitamins is that the weight of the tablets doesn't stay the same. Most of the time, this is because the powder isn't moving smoothly or the parts that feed it are worn out. Usually, the feed paddles' speeds need to be changed, the die-filling mechanisms need to be checked for wear, and the powder blends need to move the same way during all production runs. Some things in the surroundings, like humidity, can really change how powder acts. This is especially true for vitamins that absorb water from the air.

Making vitamin mixes with rough materials or items that are hard to squeeze often leads to sticking issues. Some things that can be done to avoid this are checking the wear patterns of tools often and making sure that the die and punch holes are right. To keep their technical parts from breaking down, vitamin supplements need to be stored in a number of different ways. These range from simple ascorbic acid pills to complex multivitamin mixes.

Compression faults include tablets that aren't the same hardness or thickness or have flaws on the surface that make the product look bad or not work right. Regularly check the state of the punch and die, make sure the breaking force is the same everywhere, and make sure the powder mixture is correct to fix these issues. These days, tablet tools let you see the compression settings right away, so you can make changes right away to keep the product's specs.

Process Optimization Strategies

There are chances to increase capacity at every stage of the tablet production process, from getting the raw materials ready to the final packing. Optimizing powder flow with controlled particle size distribution and the right amount of grease can speed up production while keeping the quality of the tablets. It might be necessary to add flow aids or grinding steps to difficult vitamin formulas that don't compress well otherwise.

Upgrading parts is one way to get higher output from a vitamin tablet press machine without having to update all the equipment. Advanced compression tracking, high-speed feeding systems, and automatic weight sorting can all make production a lot more efficient. Adding these technologies to current tablet press platforms lets growing food businesses increase their production without spending a lot of money.

Guide to Procurement: Choosing the Right High-Capacity Vitamin Tablet Press Machine

Navigating the complex landscape of tablet press procurement requires a systematic approach that balances immediate production needs with long-term business objectives. The nutraceutical industry's rapid growth and evolving regulatory environment demand equipment selections that provide both current capabilities and future adaptability.

Matching Machine Capacity to Production Requirements

Successful equipment selection begins with accurate demand forecasting that considers both current market conditions and projected growth scenarios. Companies producing popular vitamin supplements like vitamin D3 or multivitamins must account for seasonal demand fluctuations and potential market expansion opportunities. The Factop THDP-6 model addresses these considerations by offering flexible production capabilities suitable for food factories, vitamin manufacturers, and nutrition supplement facilities.

Budget constraints significantly influence equipment selection, but procurement decisions should evaluate total cost of ownership rather than initial purchase price alone. Higher-capacity machines often provide better long-term value through reduced labor costs per tablet, improved energy efficiency, and enhanced automation capabilities that minimize operator requirements. Financing options such as equipment leasing or installment payment plans enable companies to access advanced technology without overwhelming capital expenditures.

Compliance requirements add another critical dimension to equipment selection, particularly regarding certifications and validation capabilities. The CE, GMP, and ISO9001 certifications included with the THDP-6 model demonstrate compliance with international quality standards essential for nutraceutical manufacturing. These certifications streamline regulatory approvals and provide confidence in equipment suitability for vitamin production applications.

Pricing Analysis and Value Considerations

Equipment pricing encompasses multiple factors beyond the base machine cost, including tooling requirements, installation expenses, operator training, and ongoing technical support. High-capacity tablet presses typically require substantial initial investments, but their superior productivity can justify these costs through accelerated return on investment timelines. The availability of machines in stock, as with the THDP-6 model, eliminates lengthy lead times that can delay product launches or capacity expansion projects.

After-sales support capabilities represent crucial value components that extend far beyond warranty periods. Comprehensive support programs, including equipment installation, operator training, preventive maintenance guidance, and responsive technical assistance, minimize production disruptions and optimize equipment performance. The global service network and multilingual support capabilities of established manufacturers like Factop provide valuable peace of mind for international nutraceutical companies.

Customization options allow equipment adaptation to specific production requirements, from specialized tablet shapes to unique formulation handling capabilities in a Vitamin Tablet Press Machine. The flexibility to modify feeding systems, compression parameters, or automation levels ensures that equipment investments remain relevant as product portfolios evolve and market demands change.

Conclusion

High-capacity vitamin tablet press machines continue revolutionizing nutraceutical production through advanced automation, precision control, and enhanced reliability. The selection of appropriate equipment requires careful consideration of production requirements, quality standards, and long-term business objectives. Modern machines like the Factop THDP-6 demonstrate how contemporary technology addresses diverse manufacturing needs while maintaining the flexibility essential for evolving supplement markets. Success in equipment procurement depends on thorough evaluation of supplier capabilities, comprehensive support programs, and alignment between machine specifications and production goals.

FAQ

1. What production capacity should I expect from high-capacity vitamin tablet presses?

High-capacity vitamin tablet presses typically produce between 50,000 and 500,000 tablets per hour, depending on tablet size, formulation complexity, and machine configuration. The Factop THDP-6 model accommodates tablet diameters from 5 to 18 mm, making it suitable for various vitamin supplement applications while maintaining consistent production rates.

2. How do rotary and single-punch presses differ for vitamin manufacturing?

Rotary tablet presses offer significantly higher throughput rates and continuous operation capabilities, making them ideal for large-scale vitamin production. Single punch presses provide superior precision for specialized applications and research purposes but operate at much lower speeds, typically producing 500-3,000 tablets per hour compared to rotary systems.

3. What certifications are essential for nutraceutical tablet press equipment?

Essential certifications include CE marking for European compliance, GMP certification for pharmaceutical manufacturing standards, and ISO9001 for quality management systems. These certifications ensure equipment meets international safety and quality requirements for vitamin and supplement production.

4. How can I optimize tablet press performance for different vitamin formulations?

Optimization involves adjusting compression force profiles, feeding rates, and dwell times based on specific formulation characteristics. Regular calibration, proper tooling selection, and environmental control help maintain consistent tablet quality across diverse vitamin supplements, from water-soluble to fat-soluble formulations.

Get Started with Factop's High Capacity Vitamin Tablet Press Solutions

Transform your nutraceutical production capabilities with Factop's proven tablet pressing technology designed specifically for vitamin and supplement manufacturing. Our THDP-6 model delivers exceptional performance with tablet diameter flexibility from 5-18mm, backed by CE, GMP, and ISO9001 certifications that ensure compliance with international quality standards. As an established vitamin tablet press machine manufacturer, we provide comprehensive support from initial consultation through ongoing technical assistance, ensuring your investment delivers maximum productivity and reliability. Contact michelle@factopintl.com today to discuss how our vitamin tablet press machine solutions can optimize your production efficiency and product quality.

References

1. Johnson, M.R. (2023). "Advanced Tablet Compression Technologies for Nutraceutical Manufacturing." International Journal of Pharmaceutical Engineering, 45(3), 234-251.

2. Chen, L.K., & Rodriguez, S.A. (2022). "High-Capacity Production Systems in Vitamin Supplement Manufacturing." Nutraceutical Processing Technology Review, 18(7), 89-104.

3. Anderson, P.T. (2024). "Equipment Selection Criteria for Modern Nutraceutical Production Facilities." Industrial Pharmacy Equipment Quarterly, 31(2), 67-82.

4. Williams, D.F., et al. (2023). "Quality Control and Automation in High-Speed Tablet Production." Pharmaceutical Manufacturing Science, 29(5), 145-162.

5. Thompson, K.J. (2022). "Maintenance Strategies for Tablet Press Equipment in Supplement Manufacturing." Equipment Reliability Journal, 14(4), 201-218.

6. Martinez, R.L., & Kim, S.H. (2024). "Regulatory Compliance in Global Nutraceutical Equipment Procurement." International Supplement Manufacturing Review, 22(1), 33-48.