A tablet pill press is a machine that utilizes exact pressure to turn powdered or grainy materials into solid, uniform pills. This important piece of pharmaceutical equipment works by putting precise amounts of powder into die holes. Upper and lower punches then press the material down with controlled force to make tablets that are all the same size. For pharmaceutical businesses, health product makers, and study sites that need to make tablets quickly and to high standards of quality, understanding how these tools work is essential.

Understanding the Tablet Pill Press: Definition and Working Principle

Core Functions and Industry Applications

Today, tablet compression machines are essential for making medicines because they turn powdered ingredients into precise, regular pills that are used in many fields. Pharmaceutical companies use these high-tech tools to make medicines, food processing plants use them to make candy tablets and throat lozenges, health product companies use them to make vitamin supplements, and research institutions use them to study formulations. Compression technology can be used in many different fields, such as the chemistry industry, which makes fertilizer tablets and disinfection pills.

People like them because they can make solid dosage forms from free powders that are the same weight, hardness, and ability to melt. These days' tablet presses can work with many different types of materials, from health supplements to pharmaceutical APIs. While they're crushing the materials, they keep a close eye on quality the whole time.

Essential Components and Their Functions

At the heart of every tablet compression system are three main parts that work together perfectly. The die decides the shape and size of the tablet by making a precisely cut hole that sets the end product's measurements. Upper and lower steel rods move vertically inside the die to make punches. These rods apply controlled compression force to powder to turn it into solid pills.

To make sure that tablets are the right hardness and density, compression rollers apply lots of pressure to tools that are pressed together. This pressure control method keeps the quality of the tablets constant and stops over-compression, which could hurt the product or equipment. The filling device carefully adds the right amount of powder to each die hole, and the release system takes out the finished tablets so they can be collected and checked for quality.

Manual Versus Automatic Operation Modes

For small-scale production and study, manual tablet presses are easy to use and don't cost much. These machines need to be operated during each compression cycle, which makes them perfect for labs that are working on new formulations or small businesses that are only making a few items at a time. Manual operation gives workers full control over compression settings, so they can change the time and pressure to get the best results with different formulas.

Automatic rotary presses are the most efficient way to make tablets because they can run continuously and have multiple places working at the same time. These tools can make thousands of tablets an hour, and built-in tracking systems make sure that the quality stays the same. Automatic presses have complex control systems that keep an eye on the weight, hardness, and thickness of the tablets in real time and make changes as needed to keep specs during production runs.

Key Benefits and Safety Considerations of Using a Tablet Pill Press

Production Efficiency and Precision Advantages

Modern tablet compression equipment, including tablet pill presses, makes production incredibly efficient, which changes how businesses of all sizes make things. When it comes to pill weight accuracy, these machines are very accurate, keeping differences within ±2% of goal specs most of the time. The constant application of crushing force makes sure that tablets are all the same hardness, which has a direct effect on how quickly they dissolve and how bioavailable they are in medicinal settings.

The number of tablets made and how they are set up have a lot to do with how fast they are made. In an hour, a high-speed rotating press can make more than 100,000 tablets. A hand press with only one spot can only make 50 to 100 tablets. This gives manufacturers the freedom to pick the tools that best suit their needs and still meet quality standards.

Modern presses have automatic features that cut down on labor costs and lower mistakes made by people. Integrated quality control systems keep an eye on important factors all the time, rejecting tablets that don't meet the requirements and keeping thorough production records to meet legal requirements.

Operational Safety and Risk Management

Procurement workers can make better decisions about tool choices and safety rules at work when they know about possible safety risks. The main dangers come from mechanical threats caused by moving parts, especially punch and die systems that are under a lot of pressure. Operators who work near these strong compression tools need to be protected by machine guards and emergency stop systems.

Another big worry is being exposed to dust, especially when working with chemical compounds or medicinal powders. Modern tablet presses have filtration systems and dust cleaning equipment to keep the work area clean and reduce the amount of contact to the user. If you are working with possibly dangerous products, you need to wear safety glasses, hearing protection, and breathing protection.

When it comes to automatic systems with complicated control panels and sensor networks, electrical safety becomes very important. Proper grounding, lockout/tagout processes, and regular electrical checks keep things running safely and keep accidents from happening during maintenance.

Maintenance Requirements for Optimal Performance

To make sure that the equipment works well for a long time and that the quality of the tablets stays the same, specific replacement plans should be made. Every day, the punch and die must be checked, all parts that touch the product must be cleaned, and working parts must be polished. It's best to do these things regularly so that the groups don't get dirty and so that you can find wear problems before they break down the product.

Monitors for pressure, speed, and weight should all be checked to make sure they are set every week as part of their maintenance schedules. It is important to keep the crushing force regulated so that it stays in line with product specs because it affects how hard and how quickly tablets break down. How often and what kind of material are being used to decide when to change a die or punch? Most tools can be compressed 100,000 to 1,000,000 times.

Preventive repair plans make devices last longer and cut down on unplanned downtime by a large amount. Full checks should be done once a year, as recommended by the manufacturer. These checks should include checking the electrical system, changing any broken parts, and updating the software. These repairs make sure that production plans stay on track and that the quality of the goods always meets government standards.

How to Choose the Right Tablet Pill Press: A Practical Buyer's Guide?

Capacity and Specification Considerations

To choose the right tablet compression tools, you need to carefully look at your current production needs and your predictions for future growth. When figuring out production capacity, you should think about the size of the tablet, the amount of compression force needed, and the output rates you want. Small drug companies might need a tablet pill press that can make 10,000 to 50,000 pills every day, while big makers need a tablet pill press that can make millions of tablets every shift.

The specs of the tablet have a big effect on the machine that is chosen. For example, bigger tablets need more crushing force and slower production speeds. The relationship between the width of the tablet and the force needed to crush it is exponential. This means that 20 mm tablets need about four times as much force as 10 mm tablets. The need for weight regularity also affects the choice of feed system. For low-dose pharmaceutical goods, precision dosing methods are important.

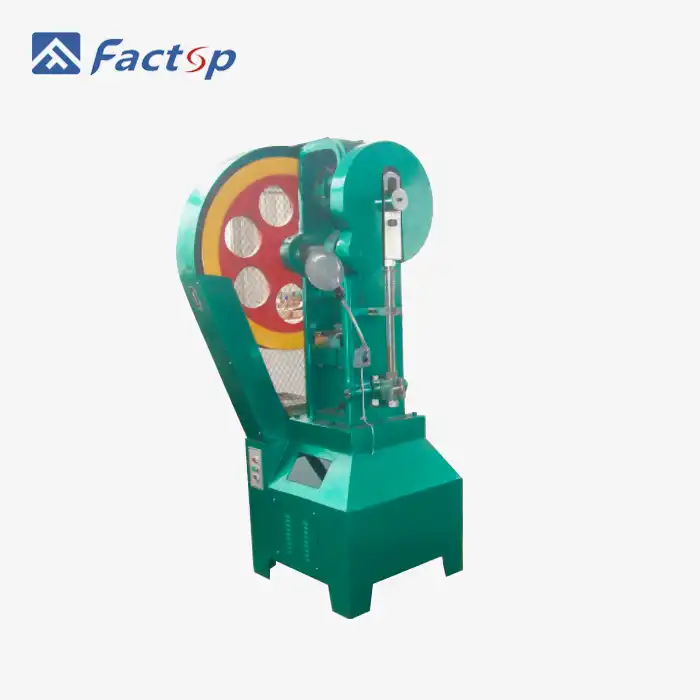

Specialized and multi-layer coatings make things more complicated, but they also give you chances to make your product stand out. With its dual-color tablet production feature, Factop's ZP420-25D model shows how advanced it is. Manufacturers can make visually appealing goods that stand out in competitive markets while still keeping the 120 KN maximum pressure needed for tough formulas.

Comparing Manual and Electric Models

Tablet presses that are operated by hand have clear benefits for study purposes and small-scale industrial settings. These tools give the operator full control over the compression settings, which lets them study in detail how the formulation behaves in different situations. Manual presses are good for startups and research schools that don't have a lot of money to spend on capital because they require less money to set up.

Electric and automatic systems offer better stability and higher production rates that are needed for business manufacturing. Precision control systems in automatic presses keep tablet specifications within very small ranges. This cuts down on waste and makes the equipment work better overall. Integrating upstream and downstream equipment makes production lines run smoothly and reduces the risk of pollution and handling errors.

The total costs of ownership, not just the initial purchase price, should be included in the cost study. Even though they require a bigger initial investment, automated systems usually have lower production costs per tablet. On the other hand, manual machines may need more skilled workers but are more adaptable for switching between products and doing experiments.

Supplier Evaluation and Procurement Strategies

When looking at possible providers, you need to look at their producing skills, quality control systems, and structures for providing help after the sale. ISO 9001 approval means that quality control systems are in place, and GMP compliance means that standards for making medicines are met. Audits of suppliers' facilities can teach you a lot about how they make things and how they check for quality.

Having the right technical help skills is very important during the installation, testing, and ongoing operation stages. For example, suppliers should offer thorough training, clear instructions, and quick expert support. Long-term running costs and production efficiency are affected by how easy it is to get extra parts and repair techs in your area.

Financing choices and deals to buy in bulk can have a big effect on how much a job costs altogether. A lot of sellers have lease programs, longer payment terms, or savings for buying a lot of machines at once. These deals help producers keep track of their cash flow while they buy the tools they need for production.

Industry Use Cases and Practical Applications

Pharmaceutical Manufacturing Standards

Pharmaceutical tablet production operates under stringent regulatory frameworks that demand exceptional precision and documentation throughout the manufacturing process. FDA regulations require validated processes, qualified equipment, and comprehensive batch records demonstrating consistent product quality. Tablet pill presses used in pharmaceutical applications must meet 21 CFR Part 11 requirements for electronic records and signatures when equipped with automated control systems.

The pharmaceutical industry demands tablet weight uniformity within ±5% of target specifications, with many products requiring even tighter control. Content uniformity testing ensures active ingredient distribution meets pharmacopeial standards, while dissolution testing verifies bioavailability characteristics. Modern tablet presses incorporate real-time monitoring systems that track these critical quality attributes throughout production runs.

Cleaning validation protocols ensure no cross-contamination between different drug products manufactured on the same equipment. The complex cleaning procedures required between product changeovers make dedicated equipment cost-effective for high-volume pharmaceutical products, while flexible manufacturing systems serve lower-volume specialty medications.

Industrial and Nutraceutical Applications

Industrial tablet applications extend far beyond traditional pharmaceuticals, encompassing diverse markets with varying quality requirements and production volumes. Chemical manufacturers produce fertilizer tablets, disinfectant tablets, and catalyst pellets using compression technology adapted for non-pharmaceutical materials. These applications often prioritize mechanical strength and dissolution characteristics over pharmaceutical-grade uniformity requirements.

Nutraceutical manufacturers face unique challenges balancing pharmaceutical-quality standards with dietary supplement economics. Vitamin and mineral supplements require careful compression to maintain potency while achieving acceptable hardness and dissolution rates. The growing demand for organic and natural health products creates opportunities for specialized formulations that require precise compression control.

Food industry applications include candy tablet production, breath mints, and nutritional supplement manufacturing. These products often incorporate flavoring agents, colors, and specialized coatings that require compatible compression equipment and carefully controlled processing conditions.

Case Studies and Best Practices

A mid-sized pharmaceutical manufacturer in the United States increased production efficiency by 40% after upgrading from manual to automated tablet compression equipment. The investment in a 25-station rotary press reduced labor costs while improving tablet weight uniformity from ±8% to ±2%, significantly reducing waste and rework expenses.

Research institutions benefit from versatile tablet presses capable of handling diverse formulations and small batch sizes. A university pharmacy school utilizes manual compression equipment for educational purposes and formulation development, allowing students to understand the relationship between compression parameters and tablet properties through hands-on experience.

Contract manufacturing organizations leverage flexible tablet compression systems to serve multiple clients with varying product requirements. The ability to quickly change over between different tablet sizes and formulations maximizes equipment utilization while maintaining strict quality standards required by pharmaceutical clients.

Conclusion

Tablet pill presses represent essential technology for modern pharmaceutical and industrial manufacturing, offering precise control over tablet production while maintaining strict quality standards. Understanding the fundamental principles, safety considerations, and selection criteria enables procurement professionals to make informed decisions that support long-term manufacturing success. The combination of advanced engineering, comprehensive support services, and proven reliability makes quality tablet compression equipment a valuable investment for companies across diverse industries seeking to enhance production efficiency and product quality.

FAQ

1. What maintenance schedule should I follow for optimal tablet press performance?

Regular maintenance includes daily cleaning of product contact surfaces, weekly calibration verification of pressure and speed controls, and monthly inspection of punch and die condition. Comprehensive annual maintenance should include electrical system testing, mechanical component replacement, and software updates to ensure continued reliability and regulatory compliance.

2. How do I ensure consistent tablet quality across different production batches?

Consistent tablet quality requires careful control of powder properties, compression force, production speed, and environmental conditions. Modern tablet presses include integrated monitoring systems that track tablet weight, hardness, and thickness in real-time, automatically adjusting parameters to maintain specifications throughout production runs.

3. What factors determine the production speed capabilities of tablet compression equipment?

Production speed depends on tablet size and complexity, required compression force, powder flow characteristics, and machine specifications. Larger tablets require more compression force and longer dwell time, reducing maximum production rates. The number of compression stations in rotary presses directly impacts hourly output capabilities.

Partner With Factop for Your Tablet Manufacturing Success

Ready to transform your tablet production capabilities with industry-leading compression technology? Factop's ZP420-25D dual-color tablet press delivers the precision, reliability, and advanced features your operation demands. Our comprehensive solution includes rapid 20-day delivery, complete installation support, and one-year spare parts coverage that protects your production investment. Contact our experienced team today at michelle@factopintl.com to discuss your specific tablet compression requirements and discover how our proven tablet pill press manufacturer expertise can enhance your manufacturing efficiency.

References

1. Pharmaceutical Manufacturing Encyclopedia: Tablet Compression Technology and Industrial Applications, 3rd Edition, Industrial Press, 2023.

2. Smith, J.R., Johnson, M.K., "Modern Tablet Press Design and Operational Principles," Journal of Pharmaceutical Manufacturing Technology, Vol. 28, Issue 4, 2023.

3. International Pharmaceutical Excipients Council, "Guidelines for Tablet Compression Equipment Validation in Pharmaceutical Manufacturing," Technical Bulletin 2023-15.

4. Manufacturing Engineering Handbook: Powder Compression Systems and Quality Control Methods, McGraw-Hill Professional, 2022.

5. Wilson, A.T., Chen, L.P., "Comparative Analysis of Manual versus Automated Tablet Production Systems," Pharmaceutical Engineering Review, Volume 45, Number 3, 2023.

6. Global Pharmaceutical Equipment Standards Organization, "Best Practices for Tablet Press Selection and Procurement in Industrial Applications," Technical Report GMP-2023-08.

_1761987044972.webp)