Fully automatic Tablet Press

Product name: Multi-punches tablet machine

Max production capacity: 19200pcs/hour

Punch die number: 11

Max press diameter: 20mm

Max tablet thickness: 6mm

Fully Automatic Tablet Press - Advanced Pharmaceutical Manufacturing Solution

Are you looking to revolutionize your pharmaceutical production line? Our Fully automatic Tablet Press Model ZP-11B delivers exceptional performance with cutting-edge automation technology. This high-tech multi-punch tablet machine is great for pharmaceutical companies, health product makers, and food supplement makers because it combines precise engineering with easy operation. With an output of up to 19,200 pieces per hour, this tablet press machine guarantees consistent quality while meeting your high-volume production needs quickly and reliably.

Main Parameter

| Feature | Description |

|---|---|

| Model | ZP-11B fully automatic tablet making machine |

| Output Capacity | 19800pcs/hour |

| Tablet Diameter | 4-18 mm (adjustable) |

| Max Pressure | 80 KN |

| Motor Power | 2.2kw |

| Rotation speed | 30r/min |

| Dimensions | 620*480*1020mm |

| Weight | 220kg |

| Certification | ISO 9001:2015, CE, GMP compliant |

Why Choose Our Advanced Tablet Press Machine?

Exceptional Production Capabilities

Your production site should have high-quality tools that do great work. With its 11 precisely designed punch dies, our tablet press can make tablets that are up to 20 mm across and 6 mm thick. Because of this, you can work with different pill formulas without slowing down or lowering the quality.

The strong construction means that it will work well for a long time, even when production plans are tight. You'll like how this machine keeps the weight, hardness, and regularity of the tablets the same over long periods of time.

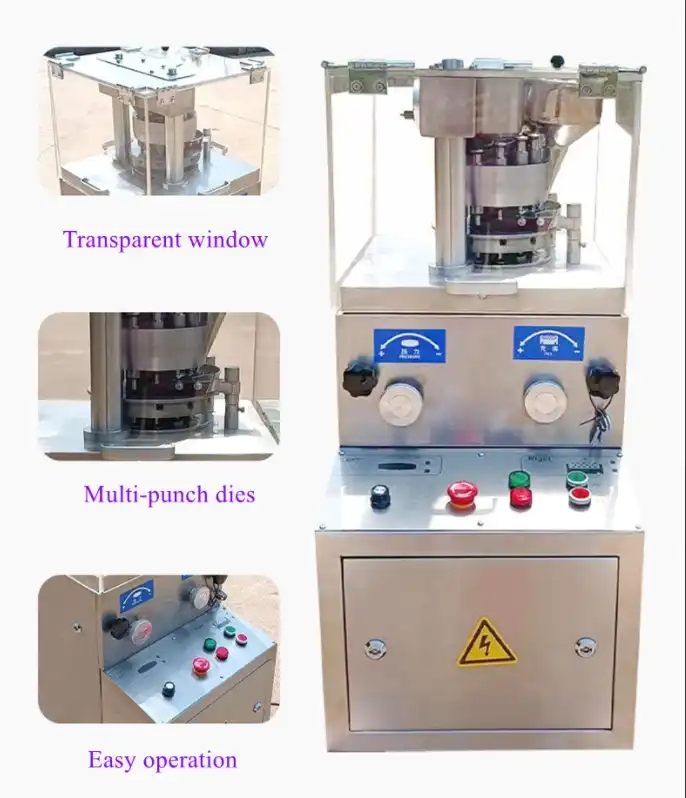

Machine Real Photos Shows

GMP-Certified Quality Standards

Quality control is very important when making medicines. Our product meets strict GMP standards, which means that your goods will meet the rules set by foreign regulators. Before it is shipped, every machine goes through strict FAT testing, so you can be sure of how well it will work right away.

The GMP-certified factory backing guarantees that your investment meets the highest industry standards. This certification demonstrates our commitment to excellence and regulatory compliance.

Quality Control

Comprehensive Support and Service

We understand that machinery downtime can significantly impact your operations. That's why we provide comprehensive support including:

- Free spare parts for one year after purchase

- On-site installation and commissioning support

- Technical guidance from our experienced team

- Wooden box export packaging for safe delivery

Our multilingual technical team ensures smooth communication throughout the installation and training process. You'll have direct access to experts who understand your specific production requirements.

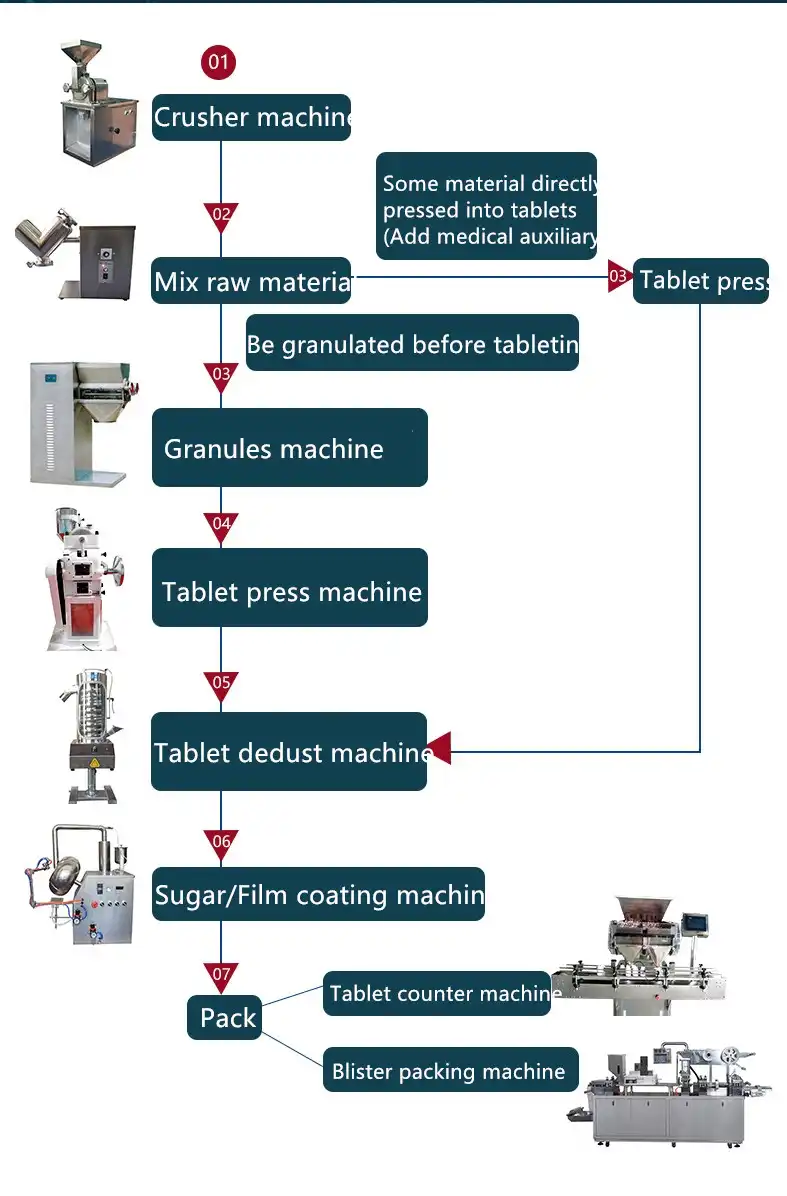

Production Process

Versatile Applications Across Industries

This tablet compression machine serves multiple sectors effectively:

- Pharmaceutical Manufacturing: Perfect for producing various medications with consistent dosing and quality control.

- Health Product Production: Ideal for manufacturing dietary supplements, vitamins, and nutritional tablets.

- Food Industry Applications: Excellent for creating compressed food products and functional food tablets.

- Hospital Preparation Rooms: Suitable for small-batch pharmaceutical preparations requiring precision and reliability.

Application Areas

Advanced Automation Features

Modern manufacturing demands smart solutions. Our Fully automatic Tablet Press incorporates advanced automation that reduces manual intervention while maximizing productivity. The intuitive control system allows operators to adjust parameters easily, ensuring optimal tablet formation every time.

The controlled flow of material through the machine is steady, and the density of each tablet is the same thanks to accurate pressure controls. All of these features work together to help you make less waste and get more done.

Global Manufacturing Excellence

Factop does business in the United States, Europe, South Africa, Korea, the Philippines, and Indonesia. This global reach shows that we are dedicated to providing reliable pharmacy equipment options to customers all over the world.

Our experienced staff knows the rules for foreign trade and can help you through the whole process of buying something. We've formed long-lasting relationships with makers in a wide range of industries, which shows that our equipment works well and is reliable.

Packaging and Transportation

Contact Us

Choosing our Fully automatic Tablet Press means investing in proven technology backed by comprehensive warranties. The one-year free spare parts coverage protects your investment while ensuring uninterrupted operations.

Fast delivery choices cut down on the time you have to wait, so you can start making things right away. The combination of our low prices and high quality makes us an excellent deal for your manufacturing plant.

Ready to transform your tablet production capabilities? Contact our expert team at michelle@factopintl.com to discuss your specific requirements and discover how our advanced tablet press technology can enhance your manufacturing operations today.

YOU MAY LIKE

_1762014629009.webp)