candyland tablet press

Model: ZP15B/19B/23B

Max production capacity: 69000ocs/hour

Rotation speed: 5-25rpm

Max tablet thickness: 1-7/6-12/8-14

Max tablet diameter: 50mm

Transform Your Confectionery Production with Our Professional Candyland Tablet Press

Are you ready to revolutionize your candy manufacturing process? Our candyland tablet press offers the perfect solution for creating uniform, high-quality confectionery tablets with exceptional precision. When you use this high-tech equipment, your candy-making line will become an efficient and reliable system. Our tools always gives you results that meet industry standards, whether you're making breath mints, candy tablets, or other high-end sweets. Your candy business will reach new heights thanks to our cutting edge technology.

Product Specifications

| Specification | Details |

|---|---|

| Model | Candyland Tablet Press |

| Max Output Capacity | 120,000 tablets/hour |

| Tablet Diameter | 3-20 mm |

| Max Pressure | 150 kN |

| Motor Power | 4.5 kW |

| Die Sets | 1-3 sets (customizable) |

| Tablet Thickness | Adjustable (1-12 mm) |

| Material of Construction | Stainless Steel 304 |

| Certification | ISO 9001:2015, CE |

Why Choose Our Tablet Press Technology for Candy Production?

There's more to making great candy pills than just mixing the ingredients. You need tools that knows how to deal with the unique problems that come up when making sweets. Our machines are careful with delicate sugar mixtures while keeping up with the speed your business needs.

It's very easy to use the ZP15B, ZP19B, and ZP23B types. They're great for both small businesses and big commercial buildings because they can make up to 69,000 pieces an hour. You have full control over the output process because the spin speed can be changed from 5 to 25 rpm.

When making candy, temperature awareness is important. Our equipment has clever settings that keep it from getting too hot while it's being compressed. This keeps your sugar-based mixtures from breaking down and makes sure that every tablet forms perfectly.

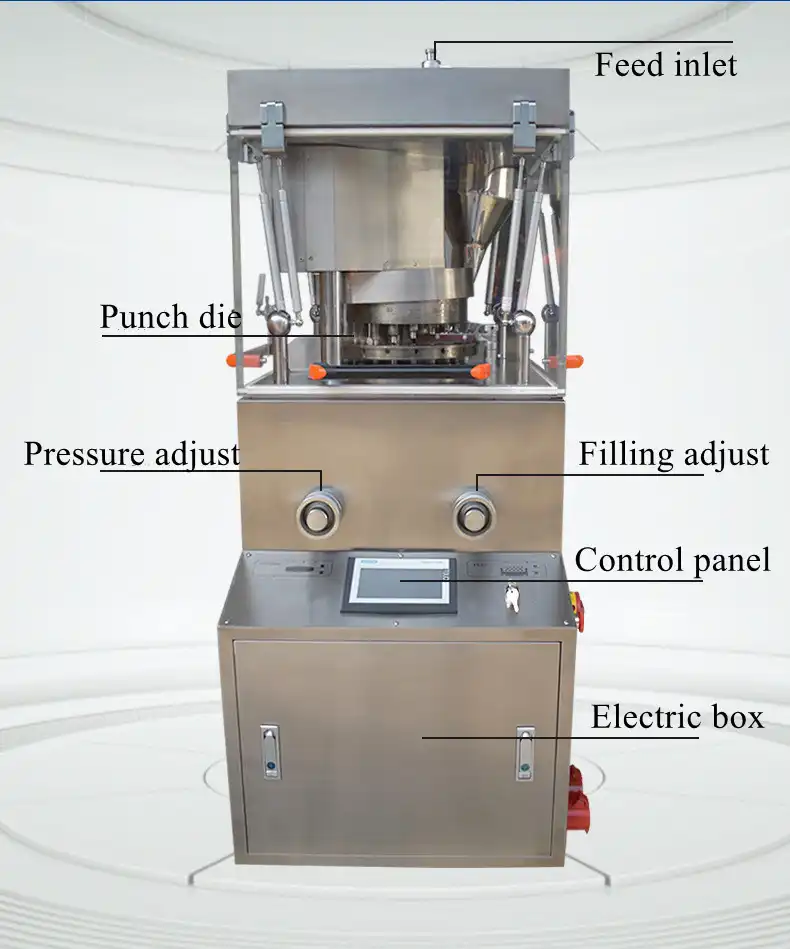

Advanced Features That Make the Difference

Precision Control Systems

The weight and width of your candy pills should stay the same. Depending on the type, our machines make tablets with thicknesses between 1 and 14 mm. With a maximum width of 50 mm, the tablet can hold candies of different sizes and shapes.

Durable Construction

Built to withstand continuous operation, these machines feature robust components that resist wear from sugar-based materials. The GMP-certified design ensures your candy production meets food safety standards.

User-Friendly Operation

Easy-to-use settings make it simple to train your staff. The simple interface cuts down on setup time and mistakes in production. You will have more time to make good candy and less time to fix problems with the tools.

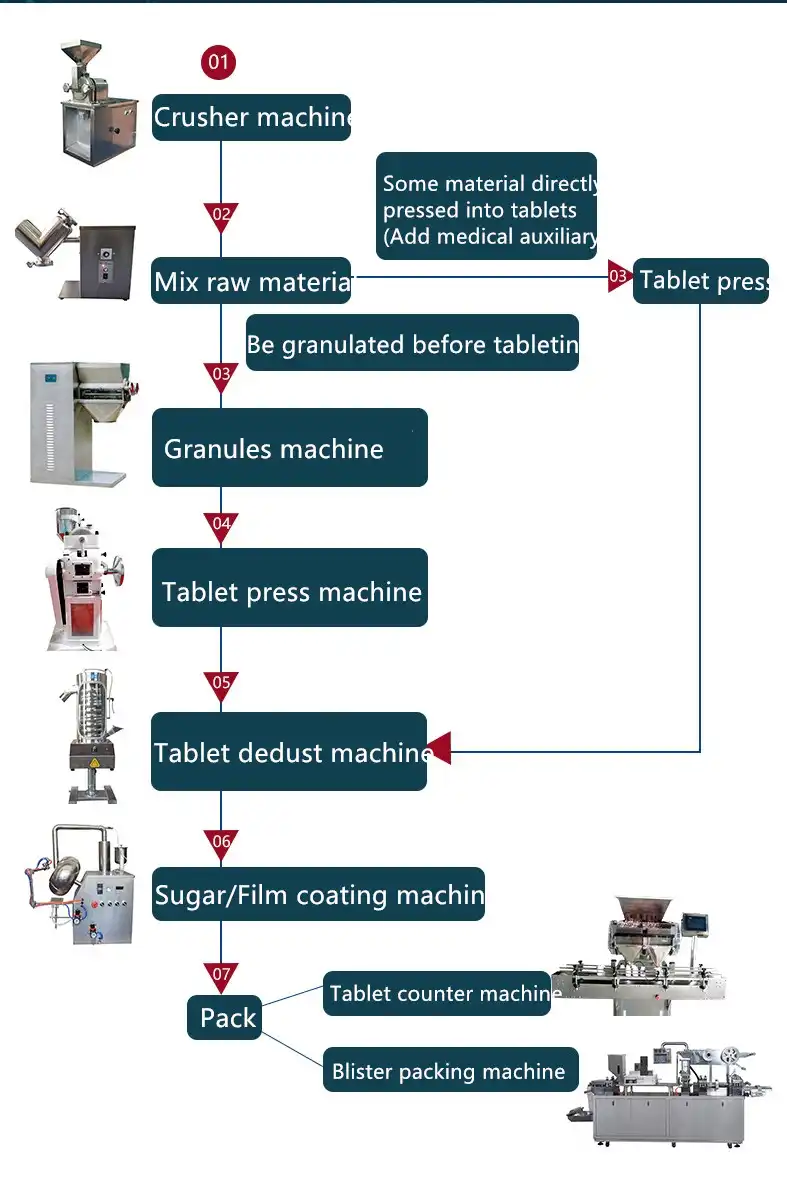

Production Process

Perfect Applications for Your Candy Business

Our tablet press technology excels in various confectionery applications:

- Breath Mints: Create perfectly compressed mint tablets with consistent flavor distribution

- Vitamin Candies: Produce health-focused candy supplements with precise dosing

- Flavored Tablets: Manufacture fruit-flavored candy tablets in multiple sizes

- Sugar-Free Options: Handle alternative sweeteners without compromising quality

Food factories and specialty confectionery manufacturers trust our equipment for reliable daily production. The wooden box export packaging ensures your investment arrives safely, ready for immediate installation.

Application Areas

Comprehensive Support for Your Success

When you choose our candyland tablet press, you're not just buying equipment. You're partnering with experienced professionals who understand your industry. Our technical team provides on-site installation and commissioning support to ensure smooth startup.

Free spare parts for one year give you peace of mind. You won't face unexpected maintenance costs during your equipment's critical early months. Fast delivery means minimal waiting time before you can start improving your production efficiency.

FAT testing and certification support validate your equipment's performance before shipment. This thorough quality assurance process prevents delays in your production schedule.

Our Wearhouse

Technical Excellence Meets Practical Design

The variable speed control accommodates different candy formulations. Harder materials may require slower compression speeds, while softer mixtures can handle faster production rates. This flexibility maximizes your output regardless of recipe requirements.

Maximum production capacity varies by model, allowing you to choose equipment that matches your current needs with room for growth. The scalable design means you can expand production without completely replacing your manufacturing setup.

Quality Assurance You Can Trust

GMP certification demonstrates our commitment to food-grade manufacturing standards. Every component meets strict quality requirements for confectionery production equipment. Your candy products will consistently meet safety and quality expectations.

Professional manufacturing expertise ensures reliable performance. Our experienced team understands the specific challenges of candy tablet production and has engineered solutions that address common industry pain points.

Qualification Certification

After-Sales Service

Contact Us

Investing in professional tablet press technology represents a significant step forward for your confectionery business. Our candyland tablet press combines proven reliability with innovative features designed specifically for candy manufacturers.

The combination of high-speed production, precise control, and comprehensive support makes this equipment an excellent choice for serious candy producers. You'll appreciate the consistent quality and increased efficiency that comes with professional-grade manufacturing equipment.

Ready to discuss how our tablet press technology can benefit your specific production needs? Contact us at michelle@factopintl.com to explore customized solutions for your confectionery business and take the first step toward enhanced manufacturing capabilities.

YOU MAY LIKE