Double rotary tablet press

Tabletting pressure: 100KN

Max production capacity: 126000pcs/hour

Motor power: 4kw

Voltage: 380V, 3phase

Dimension: 1500*1300*1650mm

Double Rotary Tablet Press ZP-35D: Professional Pharmaceutical Manufacturing Solution

Looking for reliable tablet manufacturing equipment? Our Double rotary tablet press ZP-35D delivers exceptional performance for pharmaceutical, food, and chemical industries. This machine's sophisticated engineering and GMP certification guarantee reliable tablet manufacture that satisfies global quality requirements. High-speed operation, accurate compression control, and sturdy construction intended for continuous production operations will all be advantageous to you.

Product Specifications

| Feature | Details |

|---|---|

| Pressing Force | Up to 80 kN |

| Max Tablet Diameter | 25 mm |

| Production Speed | 120,000 tablets per hour |

| Number of Stations | 30–50rpm |

| Motor Power | 7.5 kW |

| Machine Weight | 2200 kg |

| Dimensions | 1500mm x 1200mm x 1800mm |

| Tablet Thickness | 6–15 mm |

Why Choose Our High-Performance Tablet Manufacturing Equipment?

In the very competitive pharmaceutical machinery industry of today, our ZP-35D model stands out. A robust 100KN tabletting pressure mechanism is included, which can easily handle a variety of powder compositions. The machine is ideal for medium- to large-scale manufacturing operations since it can create up to 126,000 tablets per hour.

With its small dimensions of 1500 x 1300 x 1650 mm, the design may be easily integrated into your current manufacturing line. The 4kw motor's economical power usage and steady output quality will benefit your facilities. The three-phase 380V voltage system guarantees steady operation in a variety of industrial settings.

Advanced Features That Boost Your Production Efficiency

For optimal performance, this rotating tablet compression machine uses state-of-the-art technology. The dual-sided compression technology that produces consistent tablets with exact weight control will be appreciated by you. The machine may produce tablets in single or multiple layers, providing you with flexibility for a range of product needs.

Temperature control systems prevent overheating during extended operation periods. Your maintenance costs stay low thanks to the durable construction and quality components. The user-friendly interface allows operators to adjust parameters quickly, reducing downtime between batch changes.

Machine Real Photos show

Technical Specifications for Professional Applications

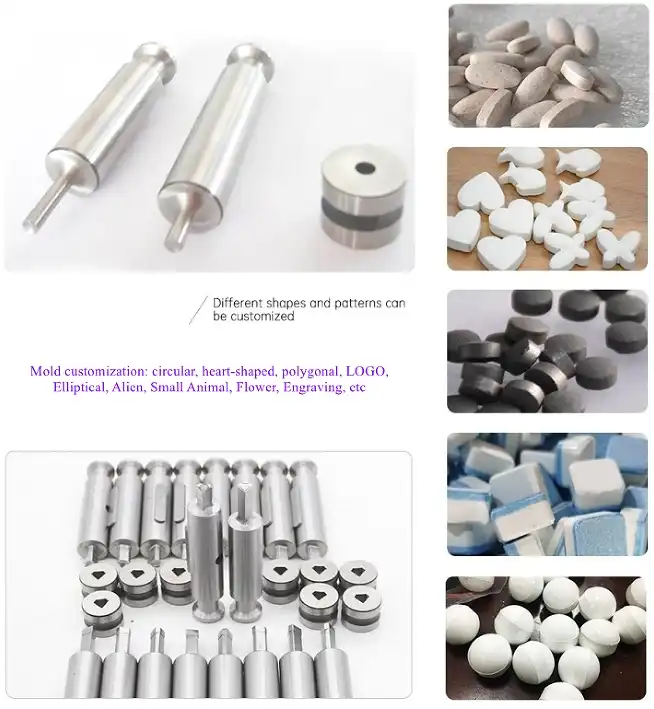

The Double rotary tablet press features robust mechanical design suitable for demanding production schedules. You can process various materials including pharmaceuticals, nutraceuticals, confectionery, and industrial chemicals. The machine accommodates different tablet shapes and sizes through interchangeable tooling systems.

Consistent tablet hardness during production runs is ensured by pressure sensors, which continually measure compression force. The dependable performance that satisfies pharmaceutical production requirements will be valued by your quality control team. The enclosed design keeps manufacturing areas clean while protecting personnel.

Quality Assurance and Manufacturing Standards

Factop's manufacturing facility meets strict GMP certification requirements. You receive equipment that undergoes comprehensive FAT testing before shipment. Our quality control process includes multiple inspection points to guarantee reliable performance from day one.

Each product comes with detailed documentation including operation manuals, maintenance schedules, and technical drawings. Your team gets complete support for installation, commissioning, and operator training. We provide wooden box export packaging to ensure safe international shipping.

Feedback from customers

Comprehensive Support Services for Global Customers

Our skilled technical staff provides international on-site assistance with installation and commissioning. To reduce unforeseen maintenance expenses, spare components are provided free of charge for the first year following purchase. Our bilingual support team can help with customs paperwork and is knowledgeable about international trade protocols.

Fast delivery schedules help you meet project timelines. Your production facility stays operational with our responsive technical support and genuine replacement parts availability. We maintain long-term partnerships with customers across America, Europe, South Africa, Korea, Philippines, and Indonesia.

Packaging and Transportation

Industries and Applications

This adaptable product efficiently serves a variety of sectors. It is used in pharmaceutical companies to make vitamins, supplements, and pharmaceuticals. Food makers provide nutritious tablets, breath mints, and compressed sweets. Catalysts, detergent tablets, and industrial chemicals are processed at chemical factories.

Hospital preparation rooms benefit from the compact design and precise dosing capabilities. Health product manufacturers appreciate the GMP compliance and contamination prevention features. Your facility gains production flexibility while maintaining regulatory compliance standards.

Application Areas

Our Workshop Show

Contact Us

Ready to enhance your Double rotary tablet press manufacturing capabilities? Contact our expert team at michelle@factopintl.com for detailed specifications, pricing information, and customization options tailored to your production requirements.

YOU MAY LIKE

_1762014629009.webp)