High speed milk tablet press machine

Model: ZP680-47/63

No. of station: 47/63 punches

Max pressure: 130KN

Max production capacity: Single 226800 Triple 75600pcs/hour; Single 169200 Triple 56400pcs/hour

High Speed Milk Tablet Press Machine - Professional Manufacturing Solution

Are you looking for reliable equipment to produce high-quality milk tablets efficiently? Our High speed milk tablet press machine delivers exceptional performance for pharmaceutical and food supplement manufacturers. This high-tech tablet pressing equipment is built to last and uses cutting-edge technology to meet your production needs. This machine makes sure that the quality of your goods is always the same and that you can make as many as possible, whether you're making calcium pills, vitamin supplements, or nutritional products.

Main Parameter

| Feature | Details |

|---|---|

| Model | ZP680-63C milk tablet press machine |

| Production Capacity | Single color 283500; Three-color 94500pcs/hour |

| Max tablet diameter | 13mm |

| Punch die No. | 63 punches |

| Maximum Pressure | 120 kN |

| Motor Power | 15KW |

| Dimensions (LxWxH) | 1560*1800*2250mm |

| Weight | 4500kg |

Advanced Features for Maximum Efficiency

Dual Configuration Options

With either 47 or 63 punch stations, our tablet press machine can be set up in a variety of ways. You can pick the setup that works best for your business needs. The output speeds of the ZP680 model are very high, which keeps your production line going easily.

Superior Pressure Capabilities

With a maximum pressure of 130KN, this equipment handles various tablet formulations with ease. The robust pressure system ensures uniform tablet density and consistent hardness across every batch. Your milk tablets will meet exact specifications every time.

Outstanding Production Capacity

Experience remarkable productivity with output rates reaching:

- Single punch: Up to 226,800 pieces per hour (47 stations) or 169,200 pieces per hour (63 stations)

- Triple punch: Up to 75,600 pieces per hour (47 stations) or 56,400 pieces per hour (63 stations)

These impressive speeds help you meet demanding production schedules while maintaining quality standards.

Quality Manufacturing Standards

GMP-Certified Production

Everything that we sell comes from a location that is GMP-certified. With this certification, you can be sure that the tools you buy will meet foreign standards for making medicines. Quality control measures are in place to protect your property.

Professional Engineering Team

Our experienced technical team brings decades of expertise to every High speed milk tablet press machine design. They understand the unique requirements of tablet manufacturing and incorporate proven solutions into each unit.

Comprehensive Testing

Each machine goes through thorough FAT (Factory Acceptance Testing) before it is sent out. This process makes sure that all systems work properly and meet the requirements. You get stuff that is ready to be set up right away.

Quality Control

Complete Service Support

Installation and Commissioning

Our technical experts complete installation and testing work on-site. Additionally, they make sure that your machine works perfectly from the very beginning. Less downtime and faster production starting are both benefits of this help.

Training and Documentation

Comprehensive operator training accompanies every installation. Your team receives detailed manuals and hands-on instruction. This preparation ensures safe, efficient operation of your new equipment.

Spare Parts Coverage

Every purchase includes complimentary spare parts for the first year. This coverage protects your production schedule and reduces operational costs during the initial period.

Company Workshop

Versatile Applications

This tablet press machine serves multiple industries effectively:

- Pharmaceutical factories producing calcium and vitamin supplements

- Health product manufacturers creating nutritional tablets

- Hospital preparation rooms making custom formulations

- Food factories producing dietary supplements

- Chemical plants manufacturing specialized tablets

The machine handles various tablet formulations including milk-based supplements, calcium tablets, and other nutritional products.

Application Areas

Professional Export Packaging

Your machine arrives safely with our specialized wooden box export packaging. This protection ensures equipment integrity during international shipping. Professional packaging reflects our commitment to quality throughout the entire process.

Global Partnership Network

Factop has established strong relationships with customers across America, Europe, South Africa, Korea, Philippines, and Indonesia. Our multilingual team understands international trade procedures and provides seamless communication throughout your purchase process.

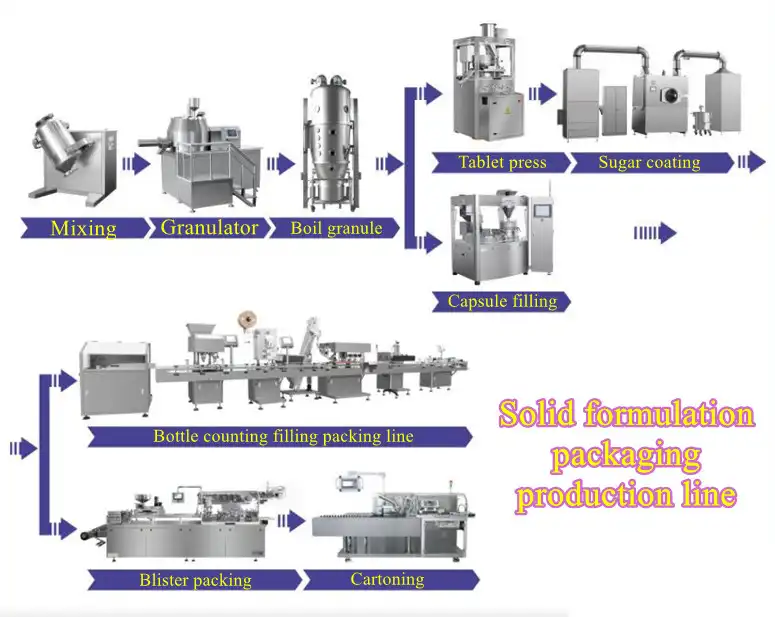

Production Process

Why Choose Factop?

We combine technical expertise with reliable service to deliver exceptional value. Our business philosophy emphasizes integrity, innovation, cooperation, and mutual success. When you choose our tablet press equipment, you join a global network of satisfied customers who rely on our technology for their production needs.

Contact Us

Ready to enhance your High speed milk tablet press machine production capabilities? Contact our team at michelle@factopintl.com to discuss your specific requirements and discover how our equipment can improve your manufacturing efficiency.

YOU MAY LIKE

_1762014629009.webp)