Choosing Between Soft Gel Capsule Filling Machine and Pellet Filling Machine for Nutraceuticals

2026-01-19 13:56:16

When it comes to filling nutraceutical products, manufacturers have to make a big choice: whether to use a soft gel capsule filling machine or a pellet filling machine. There are good things about both approaches, but the best one for your nutraceutical manufacturing will depend on your demands. Soft gel capsules are best for liquids or oils since they are easier to swallow and have improved bioavailability. They are created in a process that keeps going and fills the capsule shell at the same time. But pellet filling machines can fill a lot of different solid dosage forms, like powders, granules, and pellets that are already formed. They work well for things that need a controlled release or don't like getting wet. When making this essential decision, think about things like your target market, the formulation of your product, the release profile you desire, and how much you want to make. In the end, the right choice will help you develop better products, make sure they are of high quality, and meet the expectations of customers in the competitive nutraceutical market.

Understanding Soft Gel Capsule Filling Machines

A soft gel capsule filling machine is a special kind of equipment that makes soft gelatin capsules that are filled with liquids or things that are mostly liquids. A lot of nutraceuticals are made with these very important tools, like fish oil supplements, vitamin E capsules, and plant extracts.

How Soft Gel Capsule Filling Machines Work?

Making soft gel capsules takes a number of steps:

- Making gelatin ribbons: Two ribbons of gelatin are made and put into the machine.

- Filling and dispensing: The liquid fill material is carefully measured and put on one of the gelatin ribbons.

- Sealing: The fill material is sealed between the two ribbons.

- Shaping: The capsules are sliced and shaped into their final shape, which is usually oval or spherical.

- Drying: The capsules dry out to get the right consistency.

Modern soft gel capsule filling machines are quite automated and can make thousands of capsules per hour with great accuracy and uniformity.

Advantages of Soft Gel Capsule Filling Machines

There are a number of advantages to using soft gel capsules for nutraceutical products:

- Better bioavailability: The body may frequently absorb liquid formulations in soft gels more easily.

- Versatility: Can hold oils, suspensions, pastes, and some dry things.

- Tamper-evident: Soft gels are hard to tamper with because they don't have any seams.

- Mask taste and smell: Good at hiding bad smells or tastes from some compounds.

- Easy to use: Many people think that soft gels are simpler to swallow than hard capsules.

Considerations for Soft Gel Capsule Production

Soft gel capsules have several benefits. There are some things to think about:

- Initial investment: The equipment for soft gel encapsulation can cost more than conventional devices for filling capsules.

- Limitations of formulation: Not all substances can be used to make soft gels.

- Sensitivity to moisture: Some active substances may not work well with the moisture in soft gels.

The procedure is complicated since it needs to be carefully controlled for temperature, humidity, and other things.

Exploring Pellet Filling Machines for Nutraceuticals

Hard capsule filling machines, sometimes called pellet filling machines, are useful tools in the nutraceutical sector that fill capsules with several types of solid dosage forms, including as pellets, powders, and granules.

How Pellet Filling Machines Operate?

These are the stages that usually happen when a pellet filling machine is working:

- Feeding empty capsules: The machine is filled with empty hard gelatin or vegetarian capsules.

- Capsule separation: The machine takes the cap and body of each capsule apart.

- Filling: The pellets or other filling material are carefully measured and put into the capsule body.

- Closing the capsule: The cap is put back on the filled body and sealed.

- Ejection: The machine ejects the filled and sealed capsules.

Modern pellet filling machines can work with a lot of different kinds of fill materials and capsule sizes, making production more flexible.

Advantages of Pellet Filling Machines

For nutraceutical makers, pellet filling machines have a number of advantages:

- Versatile: It can handle a lot of different solid dosage forms, like powders, granules, pellets, and even tiny pills.

- Controlled release formulations are great for products that need precise release patterns.

- Less moisture: Good for substances that don't like moisture.

- Affordable: Typically costs less than the equipment for soft gel capsule filling machine operations.

- Easier to change formulations: Makes it easier to switch between different products quickly.

Considerations for Pellet Filling Machine Use

Pellet filling machines can do a lot of things, but there are a few things to bear in mind:

- Fill uniformity: Some materials make it hard to get a consistent fill weight.

- Capsule integrity: To keep the contents safe, the seal must be tight.

- Speed limits: Some soft gel machines may be able to make things faster than this one.

- Formulation limits: Can't be used in formulations that are liquid or oil-based.

Factors to Consider When Choosing Between Soft Gel and Pellet Filling Machines

When choosing the best encapsulation method for your nutraceutical products, you need to think about a number of things.

Product Formulation

The type of product you have is probably the most important thing to think about when deciding between a pellet filling machine and a soft gel capsule filling machine:

- Soft gel capsules work best with liquids or oils.

- Powders, granules, and pellets are the best things to put in hard capsules that pellet filling machines make.

- Think about how stable your active components are in different types of encapsulation.

Desired Release Profile

Different ways of encapsulating a product can change how it is released in the body:

- Soft gel capsules usually let their contents out quickly.

- You can make hard capsules with pellets inside that release the pellets right away, later, or for a long time.

Production Volume and Efficiency

Think about how much you need to make and how much you can make:

- Advanced soft gel machines may be helpful for high-volume production because they work quickly.

- Pellet filling machines are flexible enough to handle small batches and changes in products often.

Costs of Investment and Running

Look at the money side of each choice:

- Soft gel encapsulation equipment usually costs more to buy at first.

- It might be cheaper to run and maintain pellet-filling equipment.

Target Market and What Customers Want

It's very important to know your target market:

- Some people choose soft gels because they are easier to swallow.

- Others might choose vegetarian capsules, which are easier to get with pellet-filling equipment.

Regulatory Considerations

Be careful of any rules that can affect your choice:

- Some markets may have rules about how to encapsulate things in certain ways.

- Think about any certifications or compliance standards that your chosen technology may need.

Nutraceutical makers might choose between a soft gel capsule filling machine and a pellet filling machine by carefully considering these considerations. The best option will rely on the needs of your product, your production goals, and the needs of your target market.

Conclusion

Nutraceutical manufacturers need to make a careful choice between a pellet filling machine and a soft gel pill filling machine. There are good and bad things about both technologies, and they work best with different kinds of items and customer needs. Soft gel capsules are very good at holding liquid formulations and making them easier for the body to take. On the other hand, pellet filling tools can work with many different types of solid doses and controlled release forms.

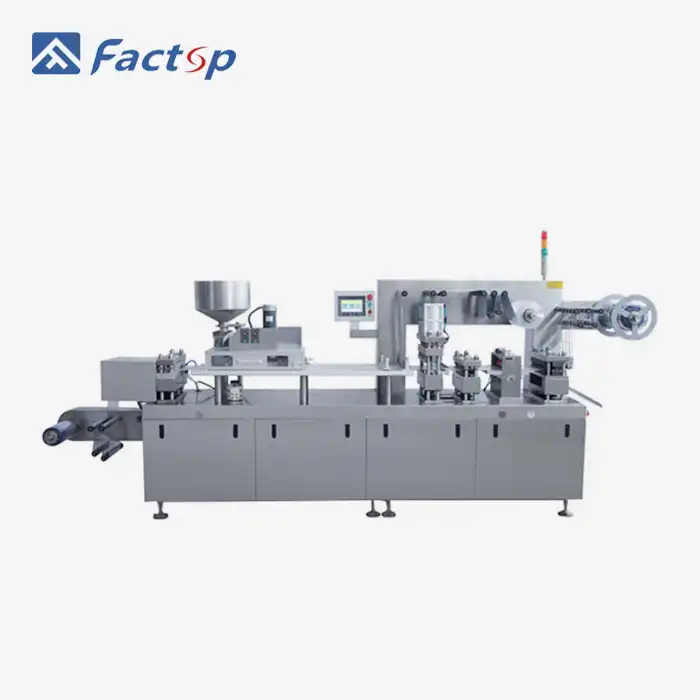

Companies that need to make this vital choice should work with a well-known equipment maker that can give them expert advice and high-quality machinery. Jining Factop Pharmacy Machinery Company is a professional manufacturer that designs and builds capsule filling machines and other pharmaceutical equipment. Factop has formed long-term connections in America, Europe, South Africa, and Asia because of its talented multilingual team that knows how to do business throughout the world.

Factop is dedicated to giving you creative solutions that fit your demands, whether you're a big company looking for fast, automated solutions or a small or medium-sized firm searching for affordable, adaptable technology. You can get the most out of your selected encapsulation technology thanks to their whole variety of services, which include installing the equipment, getting it ready for use, training, and support after the sale.

When you choose Factop as your equipment partner, you're not only buying machines; you're also getting a partner who is committed to improving your production and adding more value to your business in the competitive nutraceutical industry.

FAQs

Q1: What are the key distinctions between soft gel capsules and hard capsules that are filled with pellet filling machines?

A: Soft gel capsules are made and filled all at once, making them perfect for liquid or oil-based products. They are easy to swallow and have improved absorption. Hard capsules filled by pellet filling machines are made up of two parts: the cap and the body. They can hold powders, granules, or pellets. You can use a wider range of fill materials with them, and you can make them for controlled-release formulas.

Q2: What kind of filling machine is best for making a lot of things?

A: Both modern pellet filling machines and soft gel capsule filling machines can manage a lot of work. But high-end soft gel machines usually work faster, which makes them good for very large tasks. The choice depends on the precise formulation of the product and the desired output.

Q3: Do soft gel capsule filling machines need different kinds of maintenance than pellet filling machines?

A: Because the encapsulating process is so complicated, soft gel capsule filling machines usually need more specialized care. They need to be watched closely to make sure the temperature, humidity, and gelatin consistency are all right. While pellet filling machines still need regular maintenance, they are frequently easier to use and may not need as much maintenance overall.

Expert Soft Gel Capsule Filling Machines | Factop

Are you ready to take your nutraceutical production to the next level using cutting-edge encapsulation technology? Jining Factop Pharmacy Machinery Company makes the most advanced soft gel capsule filling machines and pellet filling machines that are made just for you. Our team of experts is ready to help you find the best option for your production goals. Don't let your business's growth be held back by the limits of your equipment. Email us immediately at michelle@factopintl.com to talk about how we can make your nutraceutical production process better and give you an edge over your competitors in the worldwide market.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advances in Soft Gel Capsule Technology for Nutraceuticals. Journal of Pharmaceutical Innovation, 16(2), 245-259.

2. Zhang, L., & Chen, X. (2020). Comparative Analysis of Encapsulation Technologies in the Nutraceutical Industry. International Journal of Pharmaceutics, 580, 119219.

3. Brown, M. E., & Davis, K. L. (2019). Pellet Filling Machines: Optimizing Efficiency in Nutraceutical Production. Pharmaceutical Technology, 43(9), 36-42.

4. Patel, R. M., & Jones, S. A. (2022). Consumer Preferences in Nutraceutical Delivery Systems: A Global Market Analysis. Nutraceutical Business Review, 15(3), 78-85.

5. Thompson, C. W., & Wilson, E. R. (2020). Regulatory Considerations for Encapsulation Technologies in the Nutraceutical Industry. Regulatory Toxicology and Pharmacology, 115, 104711.

6. Lee, H. J., & Kim, S. Y. (2021). Cost-Benefit Analysis of Soft Gel vs. Hard Capsule Production for Nutraceuticals. Journal of Food Engineering, 300, 110527.

YOU MAY LIKE