Capsule Filling Machine Working Principles & Types

2025-11-04 11:06:21

Capsule filling machines represent a cornerstone of modern pharmaceutical manufacturing, transforming loose powder formulations into precisely dosed capsule medications. Understanding the working principles and various types of Capsule Filling Making Machines is essential for pharmaceutical manufacturers seeking to optimize production efficiency, ensure dosing accuracy, and maintain compliance with stringent regulatory standards. These sophisticated systems integrate mechanical precision with advanced automation to deliver consistent, high-quality output across diverse pharmaceutical applications, from antibiotics to nutraceuticals.

Understanding Capsule Filling Machine Working Principles

The Fundamental Mechanism of Capsule Separation

The capsule filling process begins with capsule separation, where empty gelatin or vegetarian capsules are mechanically oriented and split into two components: the cap and body. Capsule Filling Making Machines employ vacuum systems that create differential pressure across specially designed separation stations. The capsules, fed from hoppers, travel through orientation rails that position them vertically. Once properly aligned, vacuum suction holds the capsule bodies in place while mechanical pins or splitting mechanisms gently separate the caps. This separation occurs at speeds reaching 24,000 to 48,000 capsules per hour in high-performance models like the NJP-400 and NJP-800. The precision of this separation stage directly impacts downstream filling accuracy, as any misalignment or damage to capsule integrity can compromise the entire batch. Modern machines incorporate optical sensors that detect malformed or improperly separated capsules, automatically rejecting them before the filling stage to maintain quality standards.

Powder Dosing and Filling Technology

Following capsule separation, the powder dosing mechanism represents the most critical stage determining medication efficacy and regulatory compliance. Capsule Filling Making Machines utilize either dosator or dosing disc technology for powder transfer. Dosator systems employ a piston-cylinder arrangement where a precisely calibrated dosator tube descends into a powder bed, compressing the powder to a specific density before transferring it into the capsule body. This method achieves dosing accuracy of ±1-3%, as seen in Factop's NJP series. Dosing disc systems, alternatively, use rotating plates with precision-drilled cavities that capture exact powder volumes. The powder characteristics—including particle size distribution, flowability, and bulk density—significantly influence filling performance. Advanced machines feature adaptive filling algorithms that automatically adjust compression force and dwell time based on real-time powder behavior monitoring. Weight check systems integrated downstream verify each filled capsule meets specifications, with automatic rejection of out-of-specification units ensuring batch uniformity across production runs.

Capsule Closing and Ejection Systems

The final mechanical stage involves capsule closing and ejection, where caps are precisely repositioned onto filled bodies and sealed through controlled pressure application. Capsule Filling Making Machines employ closing stations that apply graduated pressure—typically 15-30 Newtons—to ensure complete cap engagement without damaging the capsule shell or causing powder leakage. The closing mechanism must account for capsule size variations (#00 to #5) and shell material properties, as gelatin capsules exhibit different mechanical characteristics than HPMC vegetarian alternatives. Following closure, ejection systems utilize pneumatic or mechanical pushers to transfer completed capsules onto conveyor systems for downstream processes. Quality inspection stations often integrate at this stage, employing vision systems that detect incompletely closed capsules, powder residue on external surfaces, or dimensional irregularities. Rejected capsules are automatically diverted to waste collection, while acceptable units proceed to packaging. This comprehensive process, when executed by certified equipment meeting GMP standards and ISO9001:2015 quality management systems, ensures pharmaceutical manufacturers deliver safe, effective medications to patients worldwide.

Types of Capsule Filling Machines Available

Manual and Semi-Automatic Capsule Fillers

Manual and semi-automatic capsule fillers serve essential roles in small-scale pharmaceutical operations, research laboratories, and pilot production facilities. Capsule Filling Making Machines in this category typically process 300-3,000 capsules per hour, making them ideal for clinical trial batch production, compounding pharmacies, and product development environments. Manual machines require operators to perform capsule orientation, powder loading, and closing operations with minimal mechanical assistance. Semi-automatic variants incorporate powered separation and closing mechanisms while retaining manual powder dosing control, offering improved consistency over purely manual methods. These machines prove particularly valuable when producing small batches of specialized formulations, testing new powder blends, or manufacturing personalized medicines. The lower capital investment—often representing 10-20% of fully automatic system costs—makes them accessible to startup pharmaceutical companies and academic research institutions. Despite limited throughput, these machines maintain dosing accuracy within ±3-5%, sufficient for many applications. Changeover between capsule sizes requires only 5-10 minutes, enabling flexible production scheduling across multiple product lines throughout a single shift.

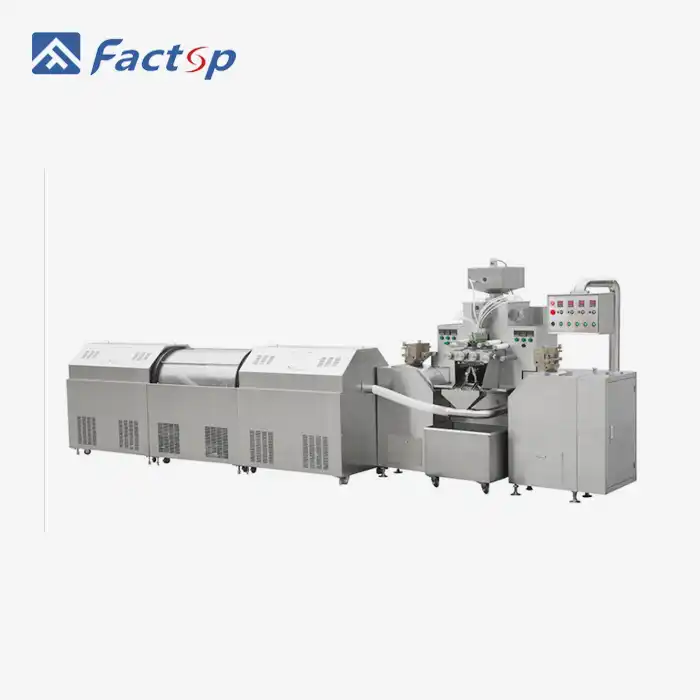

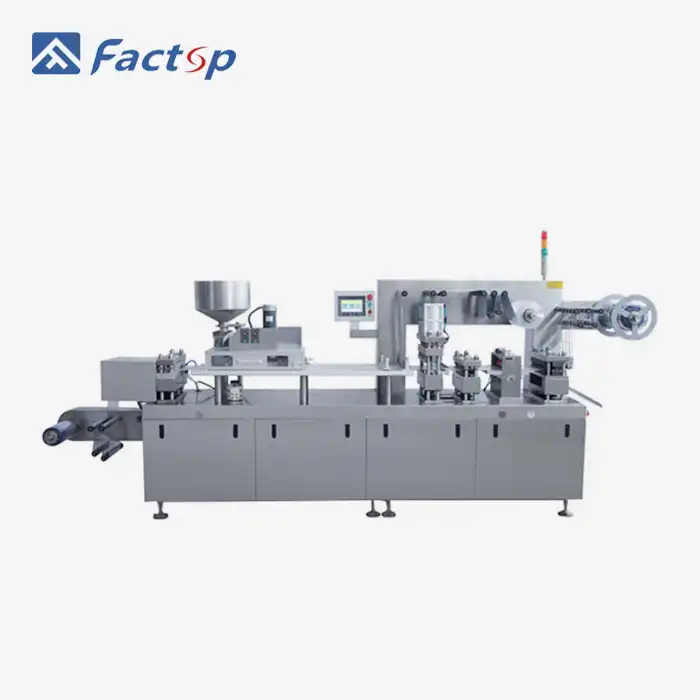

Fully Automatic High-Speed Capsule Fillers

Fully automatic high-speed capsule fillers represent the industry standard for large-scale pharmaceutical manufacturing, delivering production capacities from 12,000 to 48,000 capsules per hour. Capsule Filling Making Machines like Factop's NJP-200, NJP-400, and NJP-800 models exemplify this category, integrating advanced automation throughout the filling cycle. These systems feature continuous operation with minimal manual intervention, employing servo-driven mechanisms for precise motion control and PLC-based programming for recipe management. Automatic capsule orientation systems using vibrating bowl feeders and orientation tracks ensure consistent capsule positioning, while multiple filling stations operating in parallel maximize throughput. Real-time monitoring systems track critical parameters including fill weight, machine speed, and rejection rates, transmitting data to centralized systems for 21 CFR Part 11 compliance in FDA-regulated markets. The NJP-400 model, with its 24,000 capsules/hour capacity and ±2% dosing accuracy, demonstrates the balance between speed and precision required for commercial pharmaceutical production. Changeover times under 15-20 minutes enable multi-product production schedules while maintaining high overall equipment effectiveness (OEE). These machines incorporate automated self-cleaning systems that reduce contamination risks during product transitions and facilitate compliance with stringent GMP requirements.

Specialized Capsule Filling Equipment

Specialized capsule filling equipment addresses unique pharmaceutical manufacturing challenges beyond standard powder filling applications. Capsule Filling Making Machines designed for pellet filling incorporate gentle handling systems that prevent pellet breakage while ensuring accurate dose counting and weight verification. Liquid and paste filling machines employ precision pump systems—typically peristaltic or piston-type—that dispense viscous formulations into capsules without spillage or cross-contamination. These systems often integrate two-stage sealing processes using banding or liquid sealing to prevent leakage during storage and transportation. Temperature-controlled filling chambers maintain optimal conditions for thermosensitive formulations, while modified atmosphere systems provide inert gas environments for oxygen-sensitive compounds. Combination filling machines handle multi-particulate dosage forms, simultaneously filling different powder or pellet formulations into separate capsule compartments. Such versatility proves invaluable for complex drug delivery systems requiring immediate-release and extended-release components in single dosage units. Specialized equipment also includes containment systems for high-potency active pharmaceutical ingredients (HPAPI), featuring integrated isolation technology that protects operators from exposure while maintaining sterile processing conditions. These advanced machines typically require custom configuration to meet specific product requirements, with lead times of 3-6 months for design, manufacturing, and validation.

Key Factors in Selecting Capsule Filling Machines

Production Capacity and Throughput Requirements

Determining appropriate production capacity represents a fundamental consideration when selecting Capsule Filling Making Machines, directly impacting manufacturing efficiency and return on investment. Pharmaceutical manufacturers must analyze current production volumes, growth projections, and product portfolio diversity to identify suitable equipment. Small to medium-scale operations producing 50,000-200,000 capsules daily may find the NJP-200 model's 12,000 capsules/hour capacity sufficient, providing production flexibility with manageable capital expenditure. Large-scale manufacturers requiring 500,000+ capsules daily benefit from high-capacity machines like the NJP-800, which delivers 48,000 capsules/hour but demands higher initial investment and larger production floor space. Capacity planning must account for overall equipment effectiveness, typically 65-85% in pharmaceutical environments when factoring changeovers, maintenance, and quality control sampling. Batch size requirements also influence machine selection—smaller batches may not justify high-speed equipment's capabilities, while large production runs maximize efficiency on faster machines. Multi-product facilities should evaluate weighted average throughput needs across their product portfolio rather than focusing solely on peak capacity requirements. Additionally, future expansion plans warrant consideration; investing in scalable equipment or modular systems that accommodate capacity increases through additional stations or speed upgrades provides long-term value compared to complete equipment replacement as production grows.

Regulatory Compliance and Certification Standards

Regulatory compliance stands as a non-negotiable requirement for pharmaceutical manufacturing equipment, making certification standards a critical selection factor for Capsule Filling Making Machines. Equipment must meet Good Manufacturing Practice (GMP) standards enforced by regulatory authorities in target markets, including FDA regulations for United States distribution, European Medicines Agency (EMA) standards for EU markets, and WHO-GMP for international operations. Machines certified to these standards incorporate design features supporting validation protocols, including cleanable surfaces without product entrapment areas, documented change control procedures, and qualification documentation packages (DQ, IQ, OQ, PQ). The CE marking indicates compliance with European health, safety, and environmental protection requirements, while specific certifications like PMDA approval enable market access in Japan. Equipment supporting 21 CFR Part 11 compliance provides electronic record integrity and audit trail functionality required for FDA-regulated facilities. ISO 13485 certification demonstrates the manufacturer's quality management system meets medical device industry requirements, providing assurance of consistent equipment quality. Factop's machines hold ISO9001:2015 certification and undergo rigorous quality inspection at Product Quality Inspection Centers, ensuring compliance with international standards. When evaluating equipment, manufacturers should request complete certification documentation, validation support packages, and references from facilities that have successfully passed regulatory inspections using the equipment.

Technical Support and After-Sales Service

Comprehensive technical support and after-sales service represent critical success factors in pharmaceutical manufacturing, making these considerations essential when selecting Capsule Filling Making Machines. Equipment downtime directly impacts production schedules, regulatory compliance timelines, and ultimately patient access to medications. Manufacturers should evaluate suppliers based on their service infrastructure, including availability of 24/7 multilingual technical support, local service hubs for rapid response, and comprehensive spare parts inventories. Factop's commitment to after-sales service includes installation guidance, operator training programs, and ongoing maintenance support that minimizes production interruptions. The availability of preventive maintenance programs—scheduled inspections, wear part replacement, and calibration services—extends equipment lifespan and maintains performance specifications over years of operation. Training programs must address both operation and basic troubleshooting, empowering plant personnel to resolve common issues without external assistance. Documentation quality proves equally important; comprehensive operation manuals, maintenance procedures, and troubleshooting guides in appropriate languages facilitate effective equipment utilization. Remote diagnostic capabilities enable suppliers to assess equipment status and guide troubleshooting without on-site visits, reducing response times from days to hours. Warranty coverage terms, typically one year for major components with free accessory replacement, provide financial protection against premature failures. Long-term parts availability commitments ensure equipment remains serviceable beyond initial production runs, supporting 10-15 year equipment lifecycles common in pharmaceutical manufacturing. When comparing suppliers, request customer references and conduct site visits to observe equipment performance and assess actual service responsiveness.

Conclusion

Capsule filling machines have evolved into sophisticated systems that combine mechanical precision with digital intelligence, enabling pharmaceutical manufacturers to deliver consistent, high-quality medications efficiently. Understanding working principles, machine types, and selection criteria empowers manufacturers to make informed equipment investments that support production goals while maintaining regulatory compliance. Factop's commitment to quality, innovation, and customer success positions us as a trusted partner in pharmaceutical manufacturing excellence.

Ready to enhance your pharmaceutical production capabilities? Whether you need wholesale Capsule Filling Making Machines for large-scale operations or seeking a reliable China Capsule Filling Making Machines factory, Factop delivers certified equipment meeting international standards. As a leading China Capsule Filling Making Machines supplier and China Capsule Filling Making Machines manufacturer, we offer competitive Capsule Filling Making Machines price options with Capsule Filling Making Machines for sale across various capacity ranges. Our experienced technical team, GMP-certified factory, and comprehensive after-sales support ensure your investment delivers long-term value. Contact our team today at michelle@factopintl.com to discuss your specific requirements and discover how Factop's proven expertise in solid pharma processes can transform your production capabilities.

References

1. Johnson, M.R., & Anderson, K.L. (2022). Advanced Pharmaceutical Dosage Forms: Manufacturing and Quality Control. Pharmaceutical Technology Publishing.

2. Williams, T.S., Chen, L., & Roberts, D.A. (2023). Automation in Pharmaceutical Manufacturing: Principles and Applications. Industrial Press Inc.

3. Thompson, E.J., Martinez, P., & Singh, R.K. (2021). Capsule Technology and Development: Formulation, Manufacturing, and Quality Assurance. CRC Press.

4. Peterson, H.W., Kumar, S., & Lee, J.H. (2023). GMP Compliance in Pharmaceutical Equipment: Standards and Best Practices. Academic Pharmaceutical Sciences.

YOU MAY LIKE