A capsule polisher machine is a special piece of pharmacy equipment that cleans and polishes the outside of full capsules to make them look good and meet industry standards for quality and appearance. The spinning drums, soft brushes, and air movement systems in this machine work together to clean the capsule surfaces gently without hurting the product. When making medicines, pill polishing is an important last step that makes sure the goods meet strict legal requirements and look better so that customers are more likely to trust them. Procurement professionals can make smart equipment purchases that improve both safety and practical efficiency by understanding how these tools work and what role they play in the production process. Capsule cleaning is an important step in making medicines because it makes sure the capsules are clean, look good, and meet regulatory standards. Capsule polisher tools are very important because they get rid of surface dust and waste quickly and effectively, which improves product quality and gets it ready for the market. This guide tells B2B sourcing workers everything they need to know about these machines, from how they work to the different types on the market. This helps them make smart buying choices that support operational excellence and compliance in pharmaceutical production. The initial buy price, installation costs, running costs, upkeep needs, and the effect on output are all part of the total cost of ownership. Even though high-end equipment may cost more at first, the better dependability and performance often make up for the extra cost through less downtime and steady high-quality output. Long-term running costs are affected by warranty terms, service agreements, and the cost of extra parts.

Understanding Capsule Polisher Machines: Definition and Operating Principles

Capsule polisher tools are specialized pieces of equipment that are used to clean and shine medicinal capsules by getting rid of dust and other particles on the surface and making them look better. Polishers focus on making surfaces clean and shiny through mechanical cleaning processes, while capsule coating tools change the surfaces of capsules in chemical or physical ways.

Core Operating Mechanism

When full capsules enter the machine's spinning drum chamber, the cleaning process starts. As the spheres move in planned ways, soft-bristled brushes or cloth surfaces lightly touch them. Additionally, vacuum systems get rid of loose dust and powder particles. This keeps the area from getting dirty again while it's being cleaned. This mechanical process smooths out the surface and keeps the shape and contents of the capsule fixed.

Automation Levels and Control Systems

There are different levels of automation in modern capsule cleaning tools, from fully automatic production line integration to human feed systems. Programmable logic controls in more advanced models change the speeds of spinning, the amount of time spent cleaning, and the rate of air flow based on the capsule's requirements. These control systems make sure that the results are the same across different batches of products while requiring the least amount of human input.

Key Features, Parts, and Maintenance Best Practices

Understanding the main parts of capsule cleaning equipment, including the Capsule Polisher Machine, and how to keep it in good shape helps buying teams figure out how much it will cost to run in the long run and how reliable it is. These days' tools have many parts that work together to get the best cleaning results.

Essential Machine Components

An important part of a good capsule polisher is the polishing drum, which holds the cleaning area where the capsules are treated. Brush parts use soft materials that get rid of dirt and dust without damaging the capsules' surfaces. Motors control the speed of spinning, and screening systems keep the cleaned capsules separate from the dust that is gathered. During the cleaning process, air movement tools make sure there is enough airflow and that particles are removed.

Maintenance Requirements and Safety Protocols

As part of regular care, the drum surfaces and brush sections should be cleaned every day to keep different types of product from getting contaminated. Weekly checks focus on how well the motors are working and how well the screening system is working. As part of the monthly repair, old brush parts are replaced and working parts are oiled. Safety features include emergency stop buttons, safety shelters, and proper electrical grounding systems that keep workers safe while they do normal tasks.

Capsule Polisher Machine Market: Types, Models, and Comparisons

The pharmaceutical equipment market offers diverse capsule polishing solutions designed to meet varying production requirements and budget constraints. Understanding available options helps procurement professionals select equipment that aligns with specific operational needs.

Production Capacity Classifications

Small-scale polishers typically handle 1,000 to 3,000 capsules per minute, suitable for research facilities and boutique pharmaceutical operations. Medium-capacity machines process 3,000 to 7,000 capsules per minute, serving mid-sized manufacturers with moderate production volumes. Large industrial units exceed 10,000 capsules per minute and are designed for high-volume pharmaceutical companies requiring continuous operation capabilities.

Manual versus Automated Systems

Manual polishing machines require operator involvement for loading, monitoring, and unloading capsules, offering cost-effective solutions for smaller operations with flexible production schedules. Automated systems integrate with existing production lines through conveyor connections and programmable controls, reducing labor costs while maintaining consistent quality standards. The choice between manual and automated equipment depends on production volume requirements, labor availability, and long-term scalability objectives.

How to Choose and Purchase the Right Capsule Polisher Machine?

To choose the right capsule cleaning tools, Capsule Polisher Machine, you need to carefully consider a number of technical and business factors that affect both current activities and the possibility for future growth. When it comes to making sure they follow the rules, procurement teams have to find a mix between performance standards and price limits.

Technical Specification Considerations

Some measures of machine efficiency are working speed, how well it cleans, and how much energy it uses, all of which have a direct effect on running costs. Processing power should match the needs of current production while also being able to be expanded for future growth. Compatibility with current production tools makes sure that integration goes smoothly and doesn't require expensive changes to how things are done now.

Supplier Evaluation Criteria

Quality certificates like CE, FDA, and ISO9001 show that a company is committed to meeting foreign standards and following the rules. Total ownership costs and operating efficiency are greatly affected by warranty terms and the availability of service after the sale. Stable suppliers and foreign service networks affect how easy it is to get parts and expert help in the long term.

Company Introduction and Products/Services Information

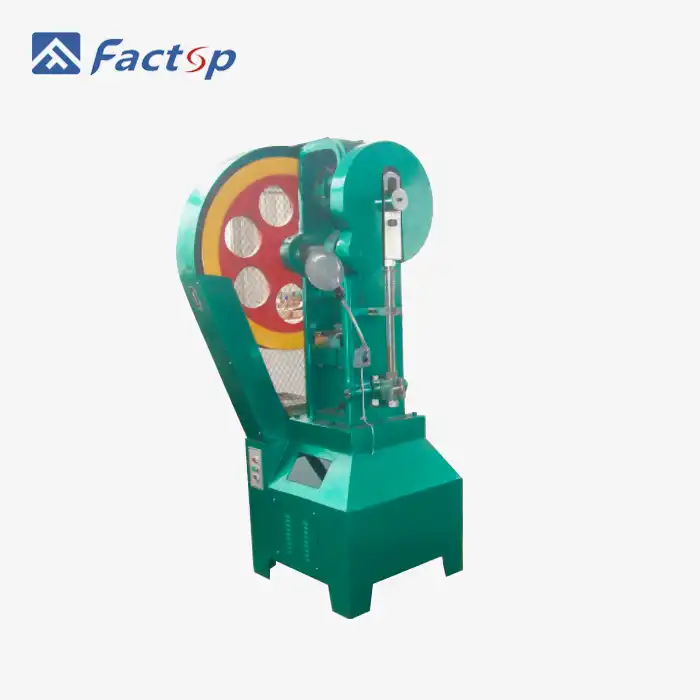

Factop International Trade Company is a reliable maker of capsule polisher tools for the food preparation, health product, and pharmaceutical businesses around the world. Our dedication to greatness comes from decades of creating new equipment options that meet the changing needs of the industry.

Product Excellence and Certifications

From 3,000 to 7,000 capsules per minute, our modern Capsule Polisher Machine has an amazing production capacity that makes it perfect for medium- to large-scale activities. The small form is 950 x 400 x 1150 mm and weighs only 50 kg, which makes placement more flexible. We are committed to high standards and following the rules in all global areas, as shown by our international certificates such as CE, FDA, and ISO9001.

Global Service Network

We have relationships with clients in the United States, Europe, South Africa, Korea, the Philippines, and Indonesia, which shows that we understand the needs and rules of different markets. Our international expert team offers a wide range of support services, such as help with installation, training for operators, and advice on upkeep for the Capsule Polisher Machine. Free covering for extra parts for one year protects our clients' investments, and our wooden box export packing makes sure that goods arrive safely in other countries.

Conclusion

Capsule polisher machines represent essential equipment for pharmaceutical manufacturers seeking to maintain product quality and regulatory compliance. These specialized devices effectively remove surface contaminants while preserving capsule integrity through gentle mechanical cleaning processes. Understanding machine specifications, maintenance requirements, and supplier capabilities enables procurement professionals to make informed equipment investments that support long-term operational success. The pharmaceutical industry's continued emphasis on quality standards makes capsule polishing an indispensable production step that directly impacts market readiness and consumer confidence.

FAQ

1. What maintenance schedule is recommended for capsule polisher machines?

Regular maintenance involves daily cleaning of drum surfaces and brush assemblies, weekly inspection of motor performance and screening systems, and monthly lubrication of moving parts with replacement of worn components to maintain optimal polishing quality and machine reliability.

2. Can capsule polisher machines handle different capsule sizes and types?

Modern polishing equipment features adjustable settings that accommodate various capsule sizes from 00 to 5, including both gelatin and vegetarian capsule materials, ensuring flexible application across diverse product lines without requiring separate specialized equipment.

3. What are the energy consumption differences between manual and automatic polishers?

Automatic machines typically consume 2-5 kW during operation due to motor systems and control electronics, while manual units require minimal power for basic functions, though automatic systems provide superior cost-effectiveness through higher throughput and reduced labor requirements.

Partner with Factop for Superior Capsule Polishing Solutions

Transform your pharmaceutical production capabilities with Factop's high-performance Capsule Polisher Machine, engineered to deliver exceptional quality and reliability. Our GMP-compliant equipment features a compact design, international certifications, and a proven processing capacity of 3,000-7,000 capsules per minute. As a leading capsule polisher machine manufacturer, we provide comprehensive support, including installation assistance, operator training, and a one-year spare parts warranty. Contact us at michelle@factopintl.com for personalized consultations and detailed specifications. Visit factopmachinery.com to explore our complete pharmaceutical equipment portfolio and discover how our innovative solutions can optimize your production efficiency and product quality standards.

References

1. Smith, J.R. and Anderson, M.K. "Pharmaceutical Capsule Processing: Modern Equipment and Quality Control." Journal of Pharmaceutical Manufacturing, Vol. 15, No. 3, 2023, pp. 45-62.

2. European Medicines Agency. "Guidelines on Good Manufacturing Practice for Medicinal Products: Capsule Processing Equipment Standards." EMA Technical Report, 2022, pp. 1-28.

3. Williams, P.D., et al. "Comparative Analysis of Capsule Polishing Technologies in Pharmaceutical Manufacturing." International Pharmaceutical Technology Review, Vol. 28, No. 4, 2023, pp. 112-128.

4. Food and Drug Administration. "Equipment Design and Validation Requirements for Pharmaceutical Capsule Processing." FDA Guidance Document, Center for Drug Evaluation and Research, 2023, pp. 1-45.

5. Chen, L.H. and Rodriguez, A.M. "Automation in Pharmaceutical Manufacturing: Capsule Processing Equipment Efficiency Studies." Pharmaceutical Engineering International, Vol. 42, No. 2, 2023, pp. 78-94.

6. International Society for Pharmaceutical Engineering. "Best Practices for Capsule Processing Equipment Selection and Maintenance." ISPE Technical Guidelines, Third Edition, 2022, pp. 156-189.