A Capsule Filling Line is an automated production system that is designed to fill empty capsules with pharmaceutical compounds, nutraceuticals, or other substances efficiently, accurately, and in conformity with regulations. When it comes to optimizing operations, reducing labor costs, and ensuring constant product quality, pharmaceutical firms cannot do without these specialized production lines. Whether it's a large-scale pharmaceutical facility or a specialized laboratory, modern capsule filling equipment reliably performs thanks to the integration of advanced automation technology and precision engineering.

Understanding Capsule Filling Lines: Definition and Core Components

Sophisticated machinery that can maximize operational efficiency while meeting tight quality standards is essential in today's pharmaceutical manufacturing. Machines that fill capsules are an essential part of this manufacturing ecosystem because they allow companies to reliably make encapsulated items of high quality.

Essential System Components

Knowing what goes into a capsule filling procedure is the first step to doing it well. All of the parts work together to keep the product together and guarantee its best performance.

The main point of entry for empty capsules into the production process is the capsule feeding system. These systems eliminate the possibility of jamming by using advanced orientation technology to guarantee correct capsule positioning. To prevent damaged capsules from reaching the filling step, modern feeding systems use sensors and automatic rejection processes to detect and eliminate them.

The process revolves around the filling stations in the Capsule Filling Line, which are responsible for precisely dosing the active chemicals into each capsule. The latest systems can handle a wide range of filling materials, such as liquid formulations, powders, pellets, and granules. Operations need to be filled accurately since it has a direct impact on product quality and regulatory compliance.

The last step in encapsulation is the sealing unit, which uses controlled pressure and heat to attach the capsule caps to the bodies. Proper closure integrity and protection of sensitive capsule materials are guaranteed by these technologies. In order to ensure that each capsule is properly sealed and to detect any possible flaws, quality control sensors keep an eye on them.

Automation and Control Systems

These days, modern capsule filling processes are able to control and monitor each step of the manufacturing process. In addition to keeping tabs on production parameters and filling accuracy, these automated systems also give operators feedback in real time. Operators may easily optimize performance across various product formulations with the use of advanced human-machine interfaces that let them swiftly and efficiently modify settings.

How Does a Capsule Filling Line Work? A Step-By-Step Process Overview

The intricacy and accuracy needed for pharmaceutical production can be better understood by manufacturers by gaining an understanding of the operational process of capsule-filling equipment. In order to keep manufacturing efficiency and product quality high, each stage must be carefully coordinated.

Capsule Loading and Orientation

Capsule loading is the first step in production in the Capsule Filling Line; automated feeding mechanisms bring empty capsules into the machine. Caps are separated from bodies and aligned for subsequent filling procedures by sophisticated orientation devices, which also assure accurate capsule positioning. In order to keep the production pace constant and avoid capsule damage, this stage demands mechanical coordination and exact timing.

The use of vacuum technology and mechanical sorting allows for the efficient handling of various capsule sizes and materials by advanced loading systems. In order to avoid problems with downstream production, quality sensors check the capsules' integrity at this step and reject those that are broken or oriented incorrectly.

Precision Filling Mechanisms

Consistent dosage across all capsules is ensured by filling operations that demand extraordinary accuracy. Depending on the properties of the material and the needs of the production process, modern systems use a variety of filling processes. To obtain precise fill weights, powder filling uses dosing wheels or tamping devices, while pellet filling uses counting systems.

In order to fill liquids precisely and without contamination, specialized pumping systems are needed. To keep the product stable when filling, these systems use temperature control and anti-foaming technologies. Each capsule gets the right dosage thanks to sophisticated weight monitoring; if a capsule's weight falls outside of certain tolerances, an automatic rejection system will remove it.

Sealing and Quality Control

By applying regulated pressure, the sealing process brings the capsule bodies back together with their caps. To close the capsule correctly without breaking its structure, this step necessitates exact timing and force control. Pressure in modern sealing systems is adjusted by feedback mechanisms that take ambient factors and the qualities of the capsule material into account.

Each sealed capsule is checked for good closure, weight, and lack of faults by the inline quality control systems. Visual inspection methods, weight checks, and integrity tests are just a few of the inspection technologies utilized by these systems. To ensure that only conforming items make it through the production line, any capsules that do not meet the quality criteria are automatically rejected.

Benefits and Advantages of Using Capsule Filling Lines for Pharmaceutical Manufacturers

Putting money into state-of-the-art capsule filling equipment has many benefits beyond just automating the process. Maximizing operational efficiency, improving product quality, and ensuring long-term corporate sustainability are all directly affected by these benefits.

Enhanced Production Capacity and Efficiency

Automated filling systems greatly outperform manual procedures in terms of production throughput in the Capsule Filling Line. The modern lines are capable of processing thousands of capsules every hour without sacrificing quality. Manufacturers can now fulfill the increasing needs of the market thanks to this capacity boost, all without having to raise wages or build more space.

The benefits of increased efficiency go beyond only faster manufacturing times. By eliminating typical causes of production delays, automating processes shortens setup times between product changeovers, reduces material waste through precision dosing, and more. Increased profits and a stronger position in the market are the immediate results of these upgrades.

Superior Quality Control and Compliance

Consistent product quality and regulatory compliance are ensured by the modern filling equipment's extensive quality monitoring systems. These technologies make it easier to submit to regulators and pass audits by documenting production parameters in great detail. With automated quality control, human error is eliminated, and quality assurance programs receive objective measurement data.

GMP compliance becomes more manageable with automated systems that incorporate built-in validation protocols and documentation capabilities. While delivering the traceability needed for regulatory compliance, these features make it easier to maintain pharmaceutical manufacturing standards.

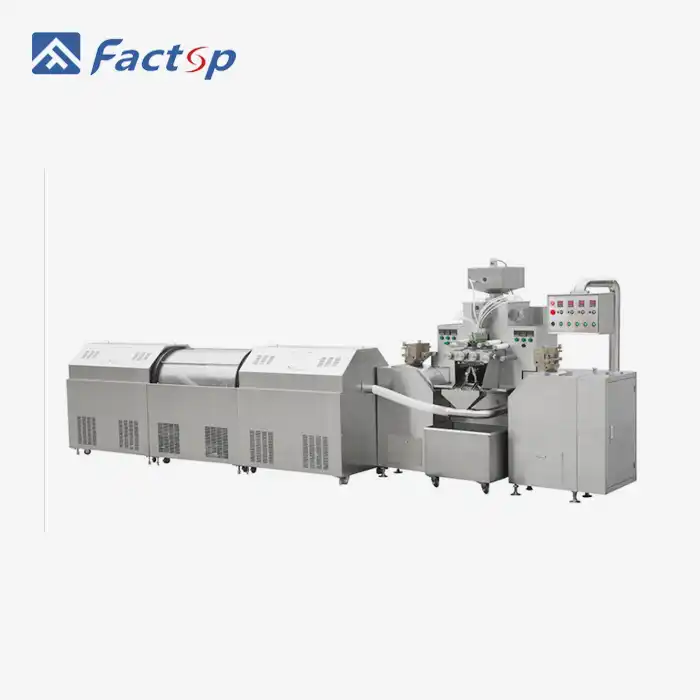

Contemporary capsule filling technology is crucial for pharmaceutical manufacturers to stay competitive because of its increased production capacity, better quality control, and simplified compliance procedures. These benefits are best illustrated by Factop's automated bottle counting filling line, which provides a one-stop shop for all of the encapsulating requirements of the pharmaceutical, laboratory, and food industries.

Choosing the Right Capsule Filling Line: Key Considerations for B2B Buyers

Careful consideration of several aspects affecting both short-term operational demands and long-term company goals is required when selecting suitable capsule filling equipment. Finding a happy medium between performance expectations, financial limitations, and long-term expansion strategies is an important part of making decisions.

Production Scale and Automation Level

The level of automation that is most suitable for capsule filling activities is mostly determined by the manufacturing volume needs. Automated solutions that maximize output while minimizing human effort are usually a boon to large pharmaceutical corporations. Continuously high-volume production and decreased per-unit manufacturing costs make these high-capacity systems worth the investment.

When considering operational scale and budget constraints, small to medium firms generally find that semi-automatic solutions work better for them. These systems are incredibly efficient compared to human operations, and they can adapt to different product lines and different production quantities with ease. Picking gear that can grow with your business is the most important thing you can do right now.

Technical Specifications and Customization Options

The parameters of the equipment should be in sync with the needs for filling material properties, manufacturing speed, and capsule size compatibility in the Capsule Filling Line. Current systems can handle a wide range of capsule sizes and filling materials; tailored setups could be necessary for certain uses. Equipment can be optimized for each manufacturer's particular product portfolio and operational requirements using customization possibilities.

Decisions on which equipment to purchase are influenced by how well it can integrate with current manufacturing lines and packaging equipment used downstream. Optimal system performance and simplified implementation are both achieved through seamless integration. Before investing in new machinery, factories should figure out how it will work with what they already have.

Support Services and Long-Term Partnership

The operational success is greatly affected by the dependability of equipment and the capabilities of the manufacturer's assistance. Installation, training, maintenance, and the availability of spare parts are all part of the comprehensive support services that guarantee optimal performance of equipment throughout its operating life. Manufacturers receive prompt assistance no matter where they are located because of Factop's global support network that includes established alliances across the Americas, Europe, South Africa, Korea, the Philippines, and Indonesia.

Technology Trends and Future Outlook in Capsule Filling Lines

Innovations in technology and shifts in consumer preferences drive continuous change in the pharmaceutical manufacturing sector. In order to make educated investment decisions and be ready for future operational needs, manufacturers benefit from having a good grasp of emerging trends.

Smart Manufacturing Integration

The Internet of Things (IoT), real-time monitoring, and predictive maintenance capabilities are transforming pharmaceutical manufacturing using Industry 4.0 technology. Sensors and networking capabilities in today's capsule filling systems allow for data analytics and remote monitoring. The ability to optimize production parameters, anticipate maintenance needs, and enhance equipment performance is a key capability for manufacturers.

Machine learning and artificial intelligence are starting to impact the capsule filling operations by optimizing processes and automating quality analysis. While lowering the bar for professional equipment operation, these innovations claim to boost production efficiency even more.

Sustainability and Environmental Considerations

The pharmaceutical industry is starting to place a greater emphasis on environmental sustainability. Efficiency in energy consumption and material waste are two key elements of today's capsule filling technology. To achieve environmental goals, manufacturers are also looking at biodegradable capsule materials and environmentally friendly production methods.

From an economic and environmental standpoint, these sustainability measures are appealing since they frequently coincide with cost reduction objectives. To meet these changing demands without sacrificing performance or quality, equipment makers like Factop are creating new solutions.

Factop's Advanced Capsule Filling Solutions

The Jining Factop Pharmacy Machinery Company is an industry leader in the development of pharmaceutical equipment, such as tablet presses, capsule filling systems, and other associated machinery. Our automated bottle-counting filling line is the result of extensive research and development in both engineering and business.

Comprehensive Product Portfolio

The pharmaceutical, laboratory, and food industries are just a few of the many that benefit from our Capsule Filling Line solutions. Whether you run a pharmaceutical plant, health product facility, or hospital preparation room, the automatic bottle counting filling line gives excellent precision and efficiency. Because of its adaptability, our machinery can meet the demands of a wide range of producers in terms of both production volume and specific applications.

Tablet press machines, granulator machines, sugar coating equipment, blister packing systems, and more may all be integrated into our systems; our capabilities do not stop with capsule filling. Instead of just having pieces of equipment, firms get a whole manufacturing ecosystem with this all-encompassing method.

Quality Assurance and Global Support

Pharmaceutical compliance is guaranteed from the moment a machine is installed since it fulfills GMP certification standards. With the backing of long-standing connections spanning many continents, our multilingual technical team offers support that is customized to meet the unique needs of each location. Regardless of their location, manufacturers can always rely on our global presence to provide them with timely help and expert knowledge.

Conclusion

Modern pharmaceutical production would not be possible without capsule filling lines, which allow for the efficient and cost-effective production of high-quality encapsulated goods. Making educated investment selections that contribute to a company's success in the long run requires familiarity with the systems' operating principles, advantages, and selection criteria. Investment in modern, adaptable capsule filling technologies positions producers for continuous competitive advantage as the sector continues to evolve through technology advancements and shifting regulatory constraints. These systems are essential for pharmaceutical firms that strive for operational excellence and regulatory compliance due to their combination of automation, quality control, and complete support services.

FAQ

Q1: What is the difference between semi-automatic and fully automatic capsule filling lines?

The loading of capsules, monitoring of activities, and removal of final products in semi-automatic systems all require human participation. These machines are ideal for small to medium production volumes, as they can process 5,000 to 25,000 capsules per hour. Continuously processing 50,000+ capsules per hour, fully automatic lines work with minimal human intervention, offering improved efficiency for large-scale manufacturing operations.

Q2: How do I determine the right capsule filling line capacity for my production needs?

A: Take a look at your operational schedule, product variety, present production volume, and expected expansion. Size of the capsule, filling material, and frequency of changeover are all important considerations. Get in touch with the makers of the machinery to make sure their specs are compatible with what you need. In order to account for expansion and production flexibility, most businesses find it beneficial to select equipment with a 20-30% surplus capacity.

Q3: What maintenance practices ensure optimal performance of a capsule filling line?

The following are necessary: routine cleaning procedures, verification of calibration, examination of components, and scheduling of preventative maintenance. Proper functioning of equipment and early discovery of problems are ensured by operator training. Follow the manufacturer's maintenance instructions and have a supply of replacement parts on hand for essential components. To ensure compliance with regulations and meet the requirements of equipment warranties, it is important to document all maintenance actions.

Partner with Factop for Your Capsule Filling Line Requirements

Ready to enhance your pharmaceutical production capabilities with state-of-the-art capsule filling technology? Factop offers comprehensive solutions as a trusted capsule filling line manufacturer, combining advanced automation with reliable global support. Our automatic bottle counting filling line delivers the precision, efficiency, and GMP compliance your operation demands. Experience the advantages of working with an established capsule filling line supplier committed to your success. Contact us at michelle@factopintl.com for detailed specifications, custom configurations, and expert consultation tailored to your manufacturing requirements. Visit factopmachinery.com to explore our complete range of pharmaceutical equipment solutions.

References

1. Smith, J.A., and Brown, M.K. "Pharmaceutical Manufacturing Technology: Modern Approaches to Capsule Filling Systems." Journal of Pharmaceutical Engineering, Vol. 45, No. 3, 2023.

2. Johnson, R.L., et al. "Automation in Pharmaceutical Production: Quality Control and Regulatory Compliance in Capsule Manufacturing." International Pharmaceutical Manufacturing Review, 2023.

3. Williams, D.C. "GMP Guidelines for Capsule Filling Equipment: Implementation and Validation Strategies." Pharmaceutical Technology and Manufacturing Standards, 2022.

4. Davis, K.M., and Thompson, S.R. "Cost-Benefit Analysis of Automated Capsule Filling Systems in Modern Pharmaceutical Manufacturing." Industrial Pharmacy Economics Quarterly, Vol. 28, No. 4, 2023.

5. Miller, P.J. "Emerging Technologies in Pharmaceutical Equipment: IoT Integration and Smart Manufacturing Applications." Advanced Pharmaceutical Manufacturing Technology, 2023.

6. Anderson, L.H., et al. "Quality Assurance Protocols for Capsule Filling Operations: Best Practices and Industry Standards." Pharmaceutical Quality Management Journal, Vol. 12, No. 2, 2023.